A Nonlinear Vibration Damping Device Coupled with Segmental Stiffness

A vibration damping device, nonlinear technology, applied in the direction of shock absorber, spring/shock absorber functional characteristics, shock absorber, etc., can solve the problem that broadband vibration reduction cannot be realized, achieve good vibration suppression effect, and low processing cost , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described in detail and completely below in conjunction with the accompanying drawings.

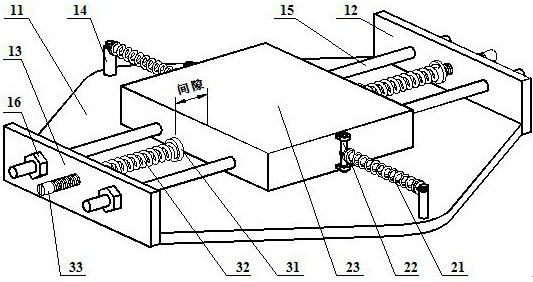

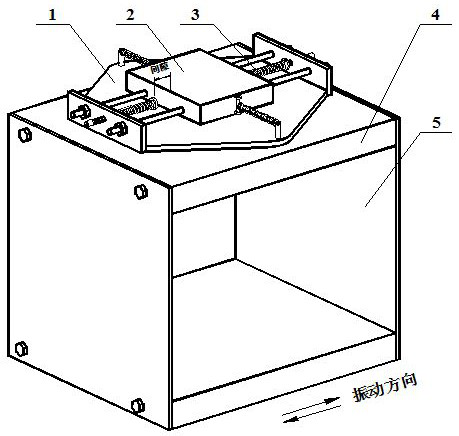

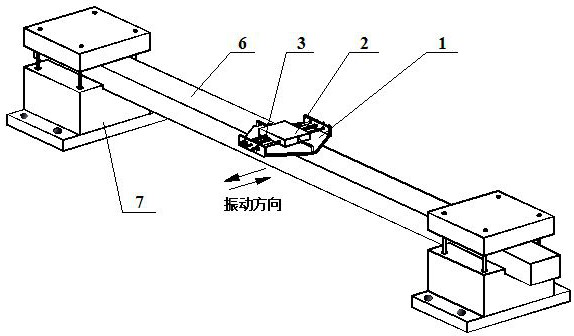

[0017] Such as figure 1 As shown, a nonlinear damping device coupled with segmental stiffness includes a fixed frame 1, a nonlinear damping device 2, and a segmented spring device 3; On the bottom plate 11, two fixing bolts 14 are assembled on the left and right sides of the bottom plate 11, and two guide rods 15 are fixed on the front fender 12 and the rear fender 13 through nuts 16; The two ends of the linear springs 21 on both sides are respectively connected with the fixed bolts 14 and the fixed pins 22 fixed on both sides of the mass block 23, the guide rod 15 runs through the mass block 23, and the mass block 23 can slide on the guide rod 15; The segmented spring device 3 is arranged front and rear, and is installed on the front fender 12 and the rear fender 13 .

[0018] The front baffle plate 12 in the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com