Wire bonding device

A wire bonding device and wire bonding technology, which are applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve problems such as poor electrode connection and achieve the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

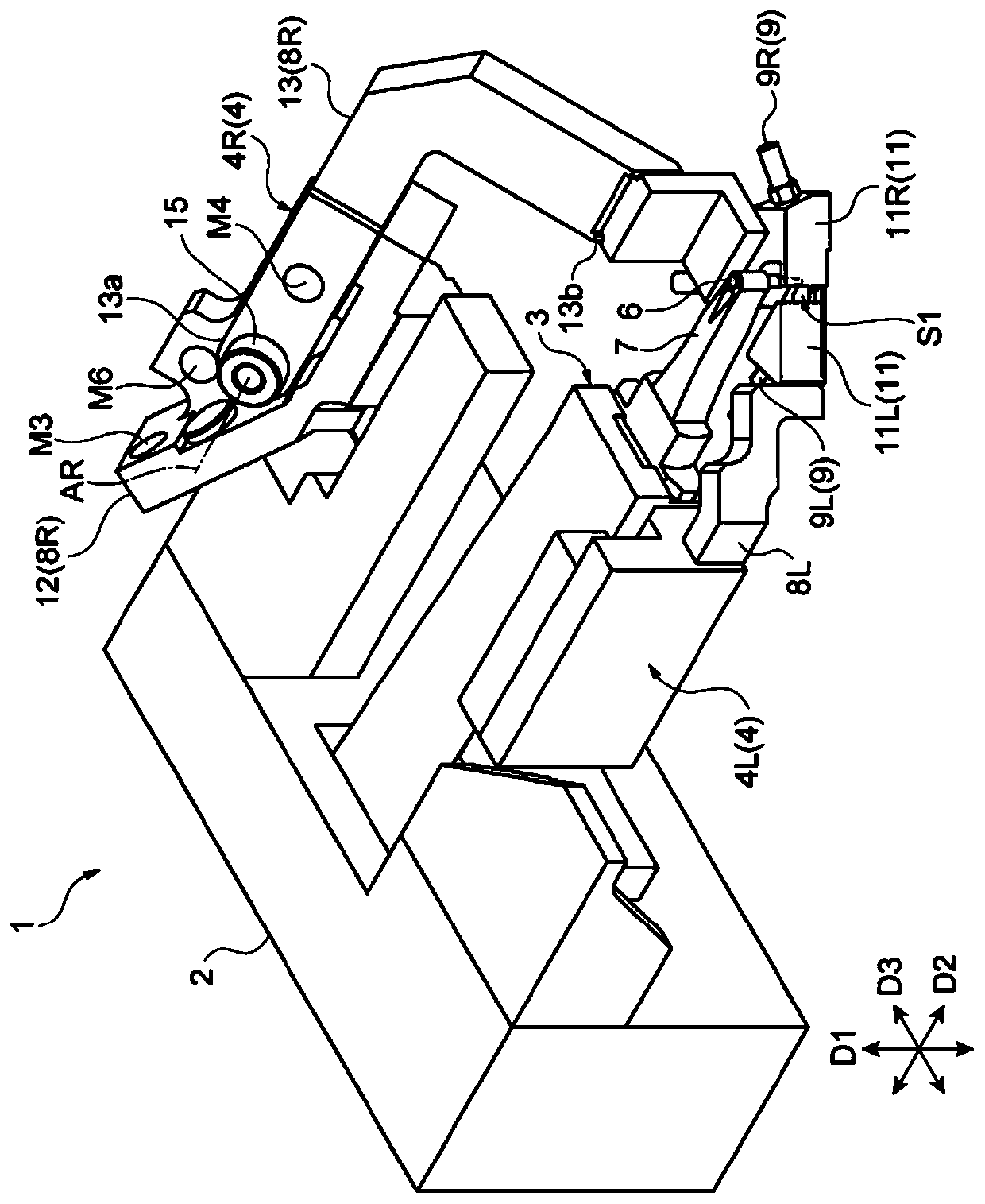

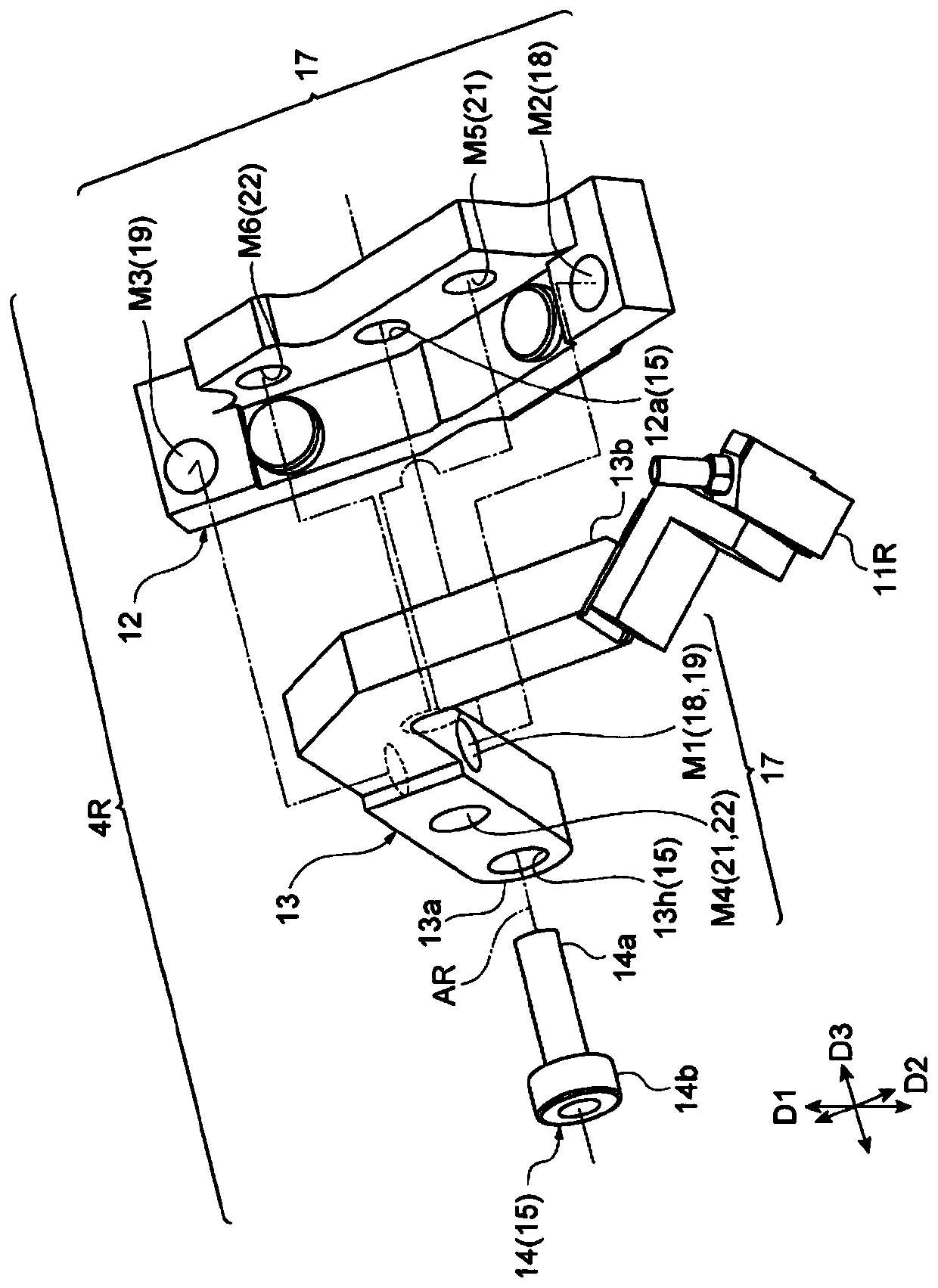

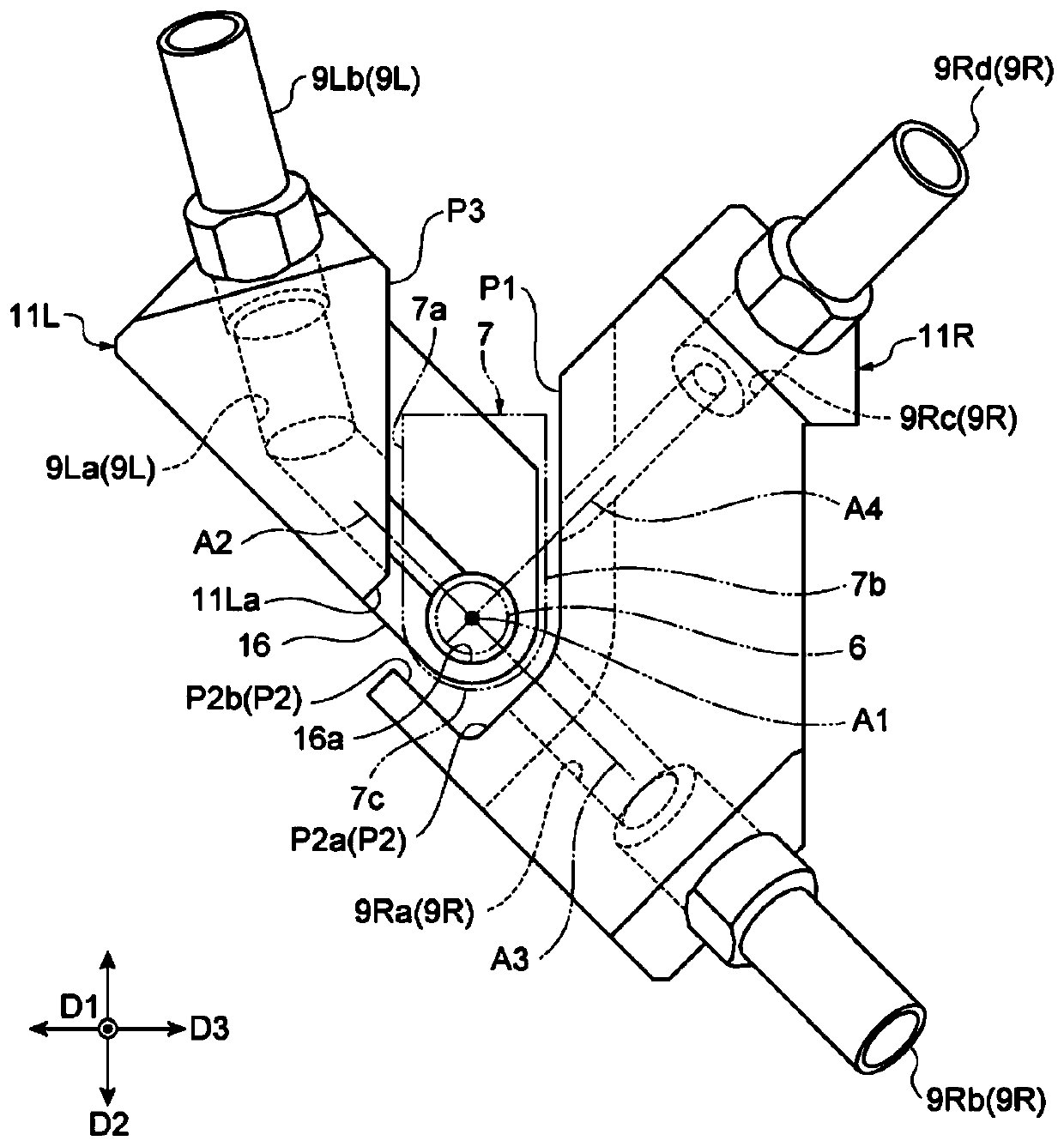

[0022] Below, refer to the attached Figure 1 The method for implementing the present invention will be described in detail. In the description of the drawings, the same components are assigned the same symbols, and repeated descriptions are omitted.

[0023] figure 1 The wire bonding apparatus 1 shown in will bond wires to electrodes of semiconductor chips or substrates. The wire bonding device 1 has a base unit 2 (base portion), a capillary unit 3 , and a chamber unit 4 . In addition, although the wire bonding apparatus 1 has other components, such as a housing|casing, a control device, and a feeder, these components are abbreviate|omitted in the following description and drawing.

[0024] The wire bonding device 1 holds wires so as to protrude slightly from the capillary unit 3 . In the holding state, a free air ball (Free Air Ball) is formed at the tip of the protruding bonding wire. Next, the wire bonding apparatus 1 performs ball bonding. Specifically, the capillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com