joint assembly device

A technology for assembling devices and metal wires, applied to welding equipment, electrical components, circuits, etc., can solve problems such as hindering heat dissipation, damage to semiconductor devices, and degradation of heat dissipation characteristics, so as to eliminate warping, reduce environmental load, and improve bonding characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the present invention is not limited to the embodiments described below.

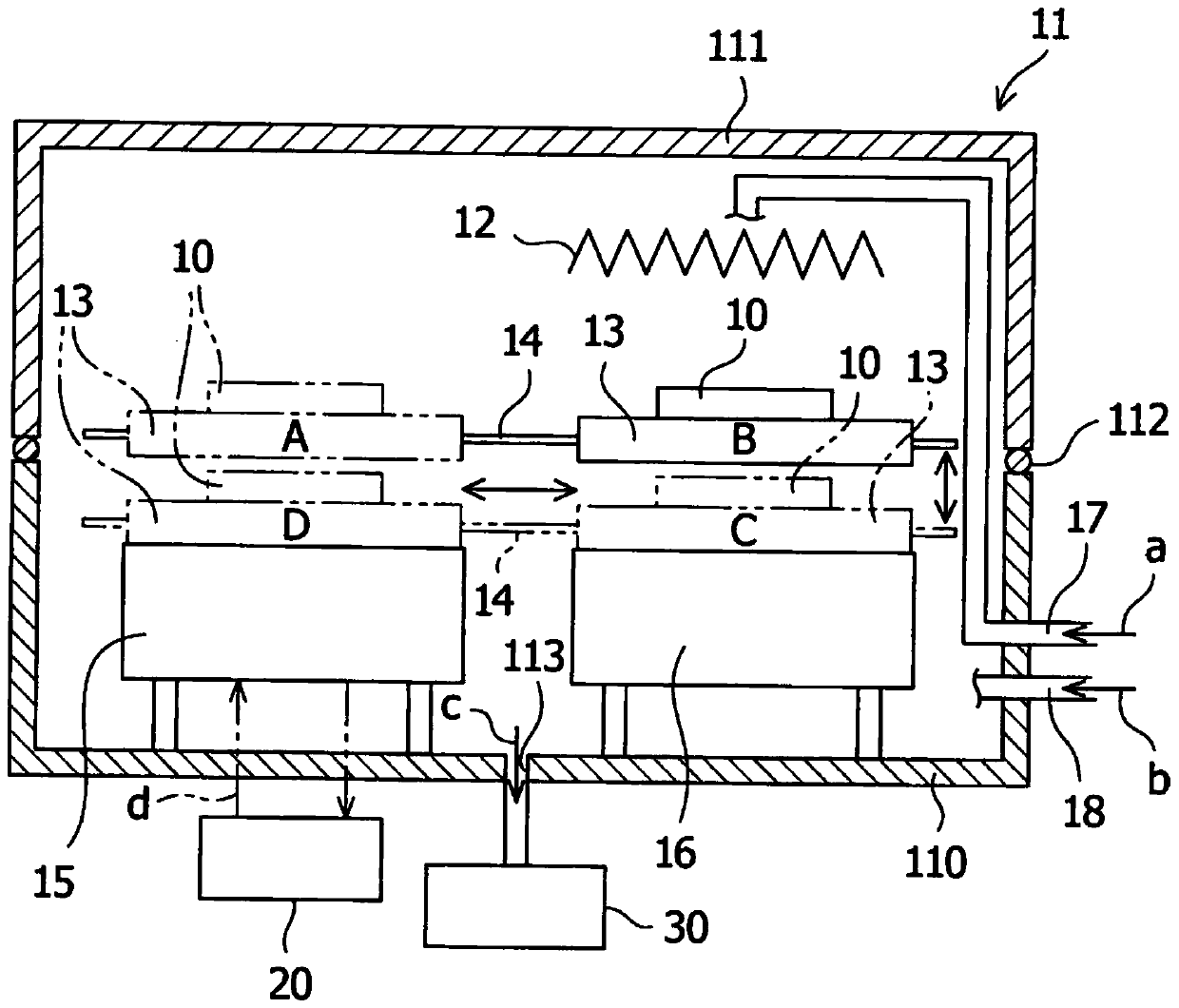

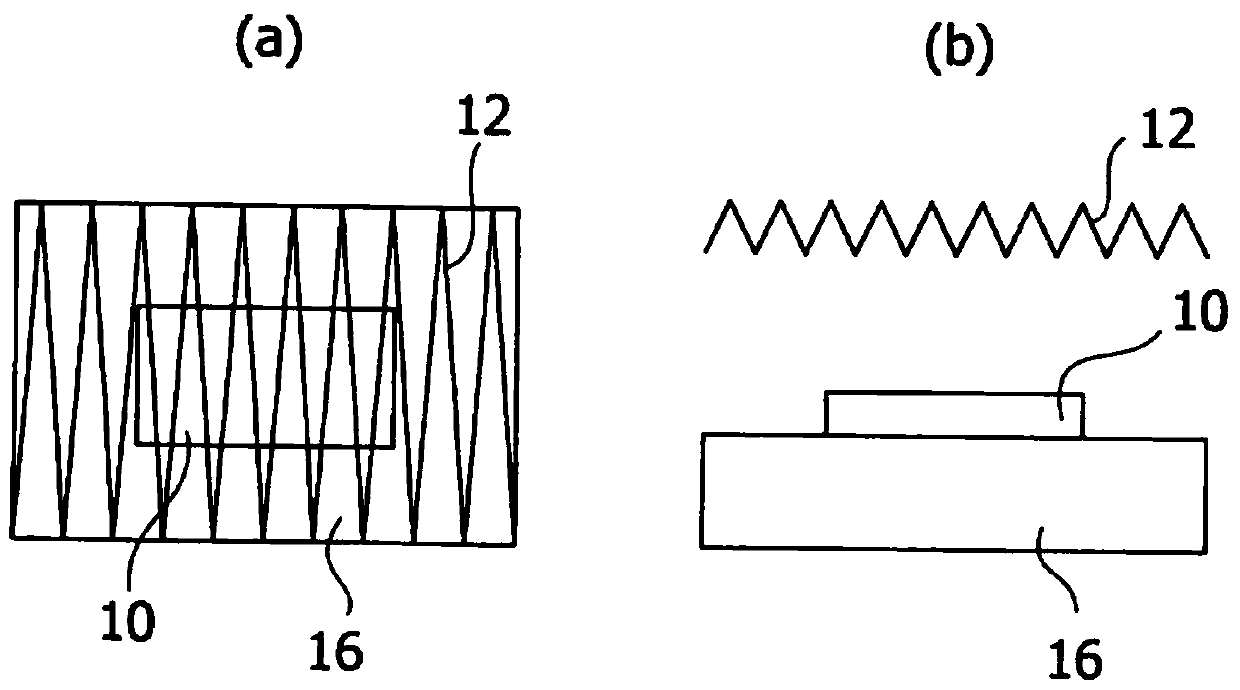

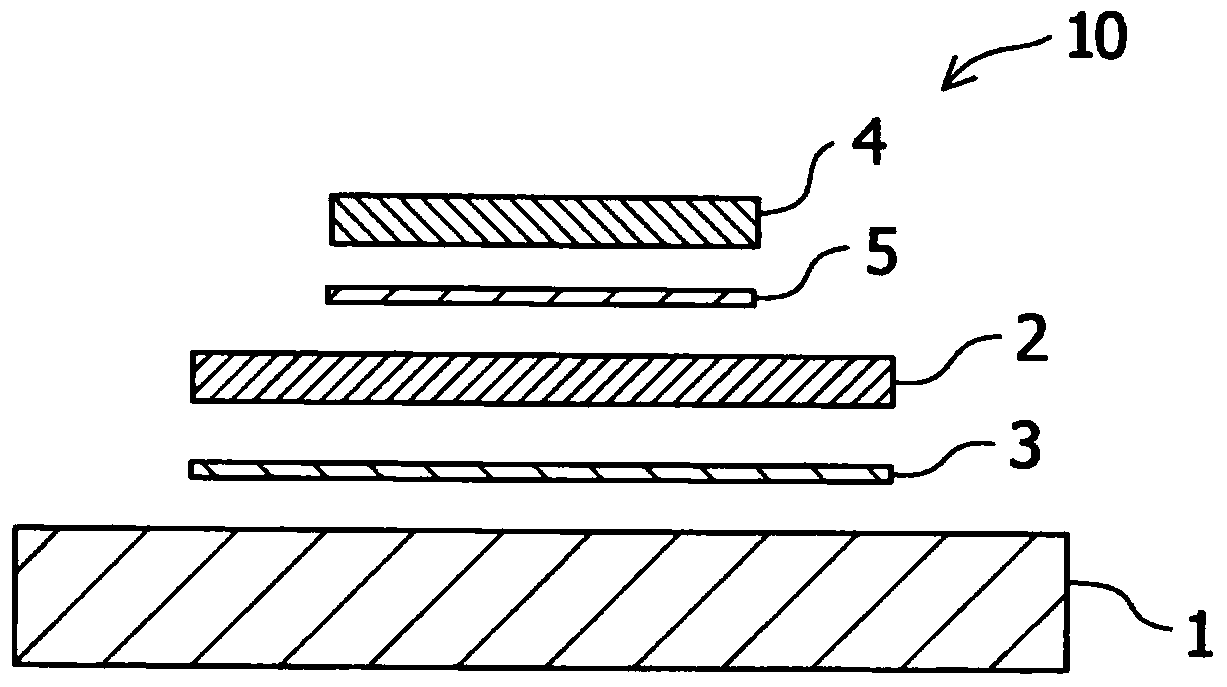

[0043] According to one embodiment of the present invention, the present invention relates to a joint assembly device. figure 1 A schematic diagram of a joint assembly device according to the present invention is shown. The bonding assembly device according to the present invention mainly includes a metal wire 12 , a transfer table 13 , a cooling plate 15 , a hot plate 16 , an active species generation gas introduction pipe 17 , and an inert gas introduction pipe 18 in a reduced pressure furnace 11 . In the present invention, the active species generating gas refers to a gas that is decomposed by contact with the metal wire 12 , has relatively high reducing properties and can generate elements containing unpaired electrons. The above-mentioned active species generating gas is not particu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com