Online detection device for filter capsule filter stick

A detection device and bead blasting technology, which is applied in sorting and other directions, can solve problems such as high brightness requirements, normal operation effects, eye damage, etc., and achieve the effects of improving test accuracy, reducing requirements, and improving detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

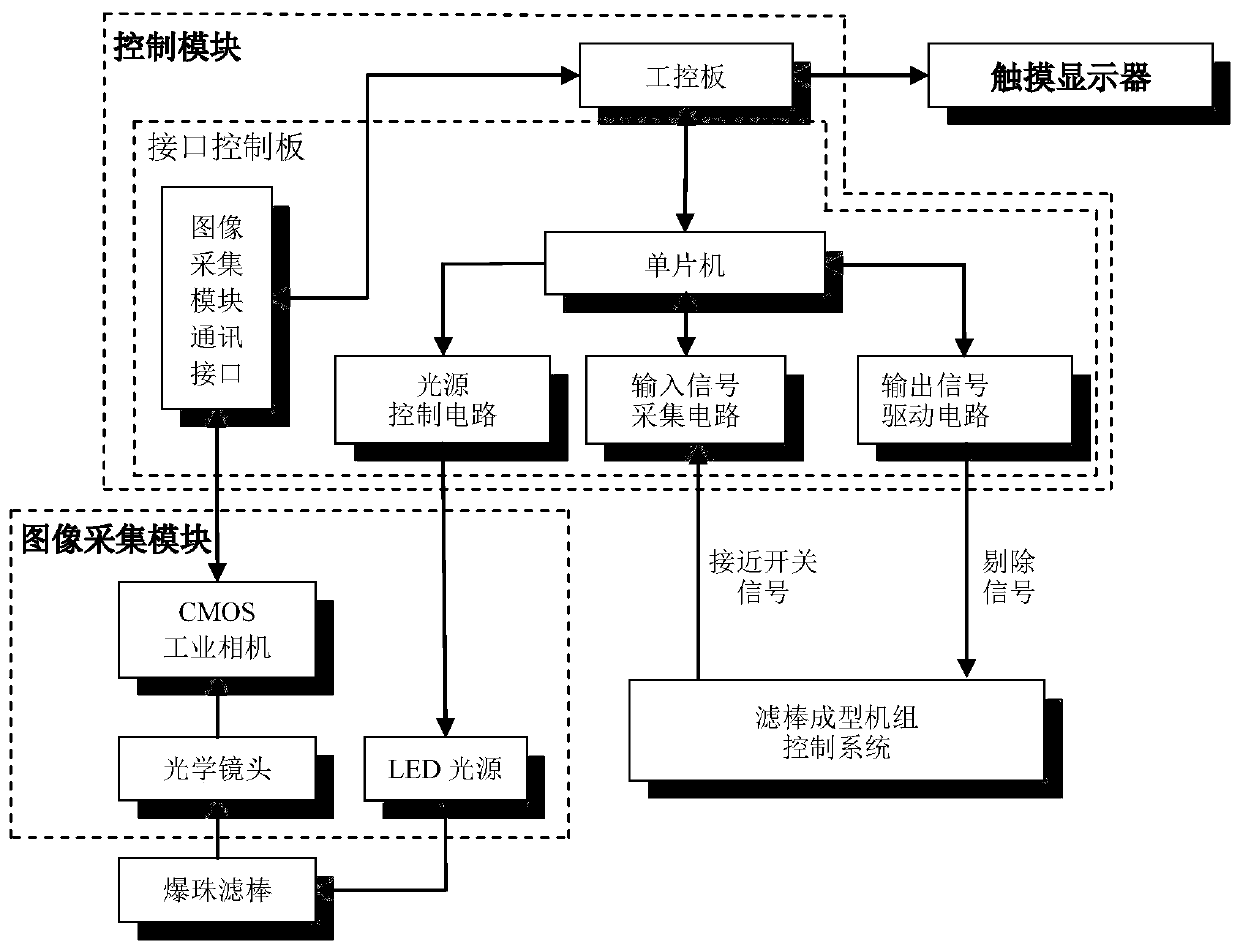

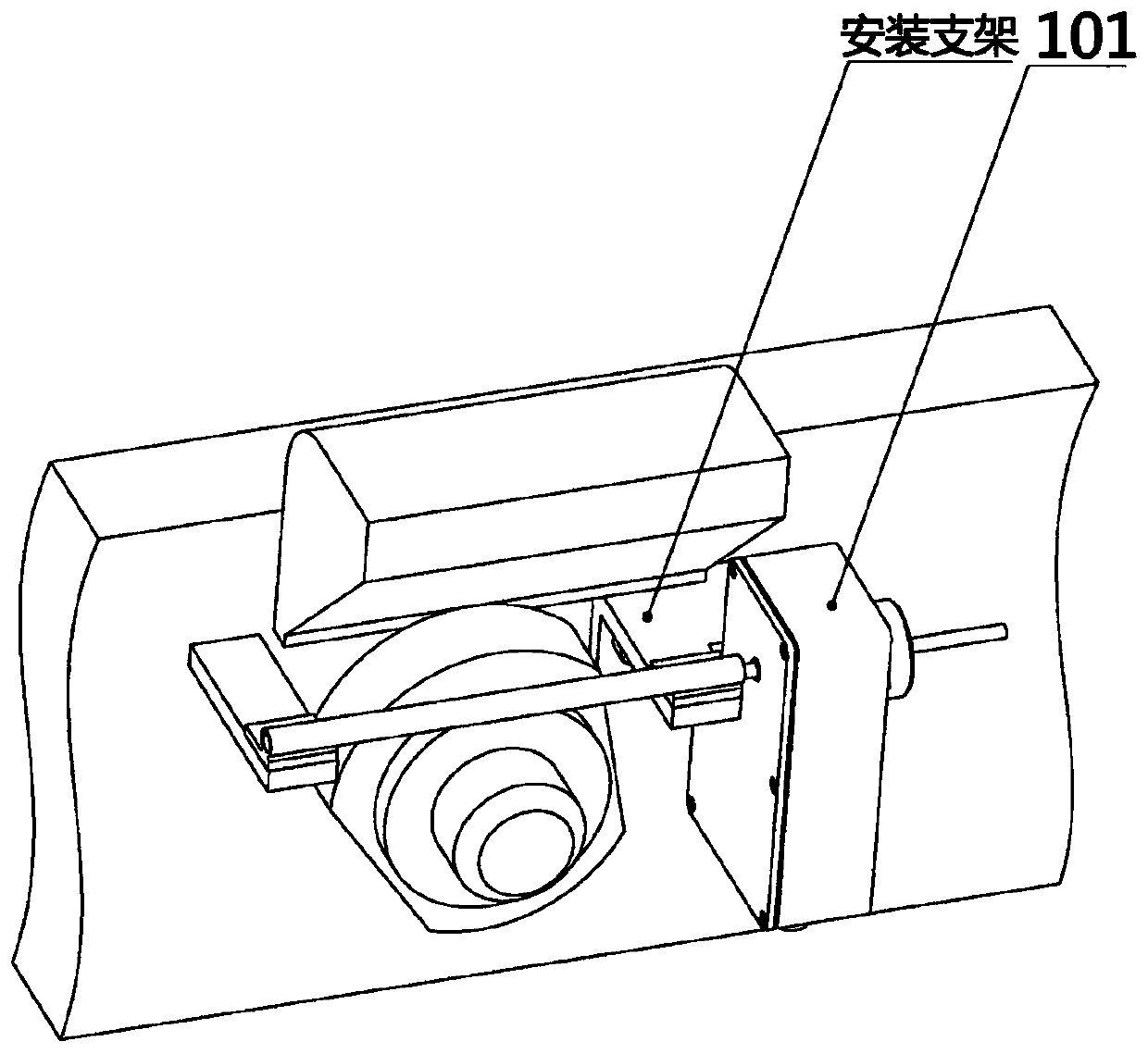

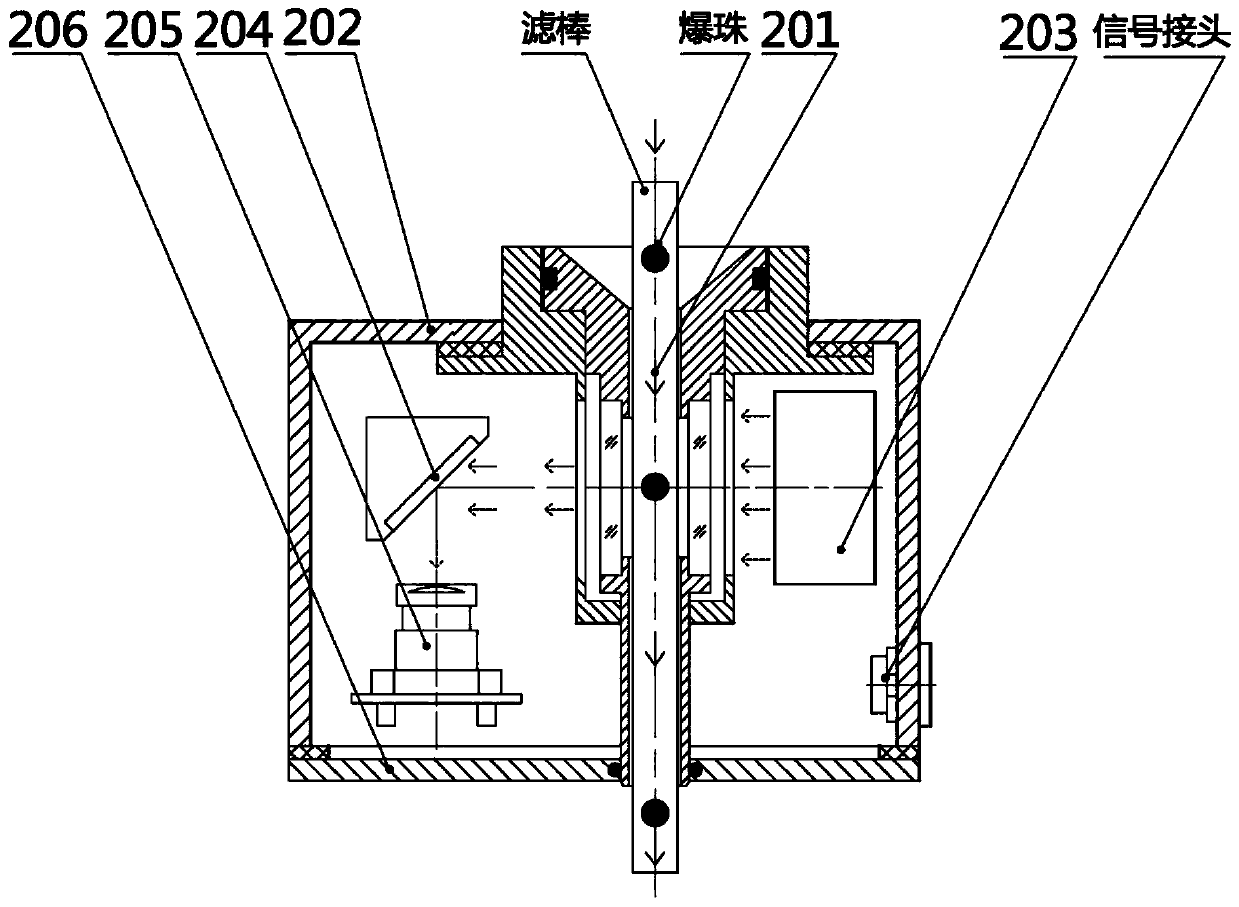

[0034] like figure 1 and image 3 As shown, an online detection device for a bead filter rod includes an image acquisition module 101, a control module 102 and a touch display screen 103. The image acquisition module 101 adopts a box-type structure and includes a detection channel 201, a housing 202 and a cover plate 206. One side of the detection channel 201 is provided with an industrial camera 205, an optical lens and a flat mirror 204, and the other side is provided with a light source 203. The image acquisition module 101 collects the image of the bead filter rod to be inspected through the industrial camera 205 and transmits it to The control module 102, the control module 102 processes the image collected by the image acquisition module and judges whether there are defects such as missing beads, beaded beads and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com