Workbench for automobile part punching

A technology for auto parts and workbenches, applied in the field of auto parts, can solve problems such as hole diameter deviation, scrap parts, drill bit deviation, etc., and achieve the effect of preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

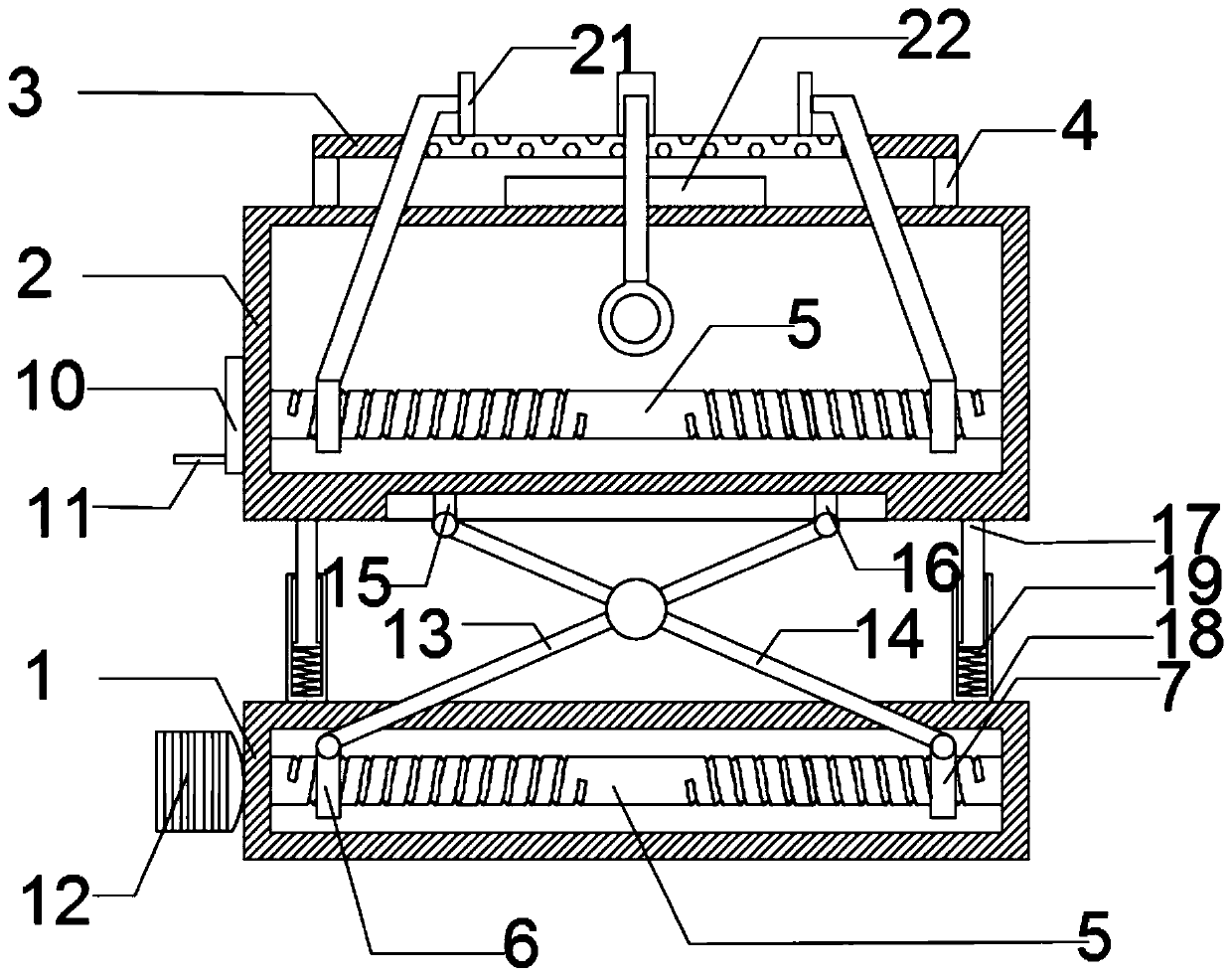

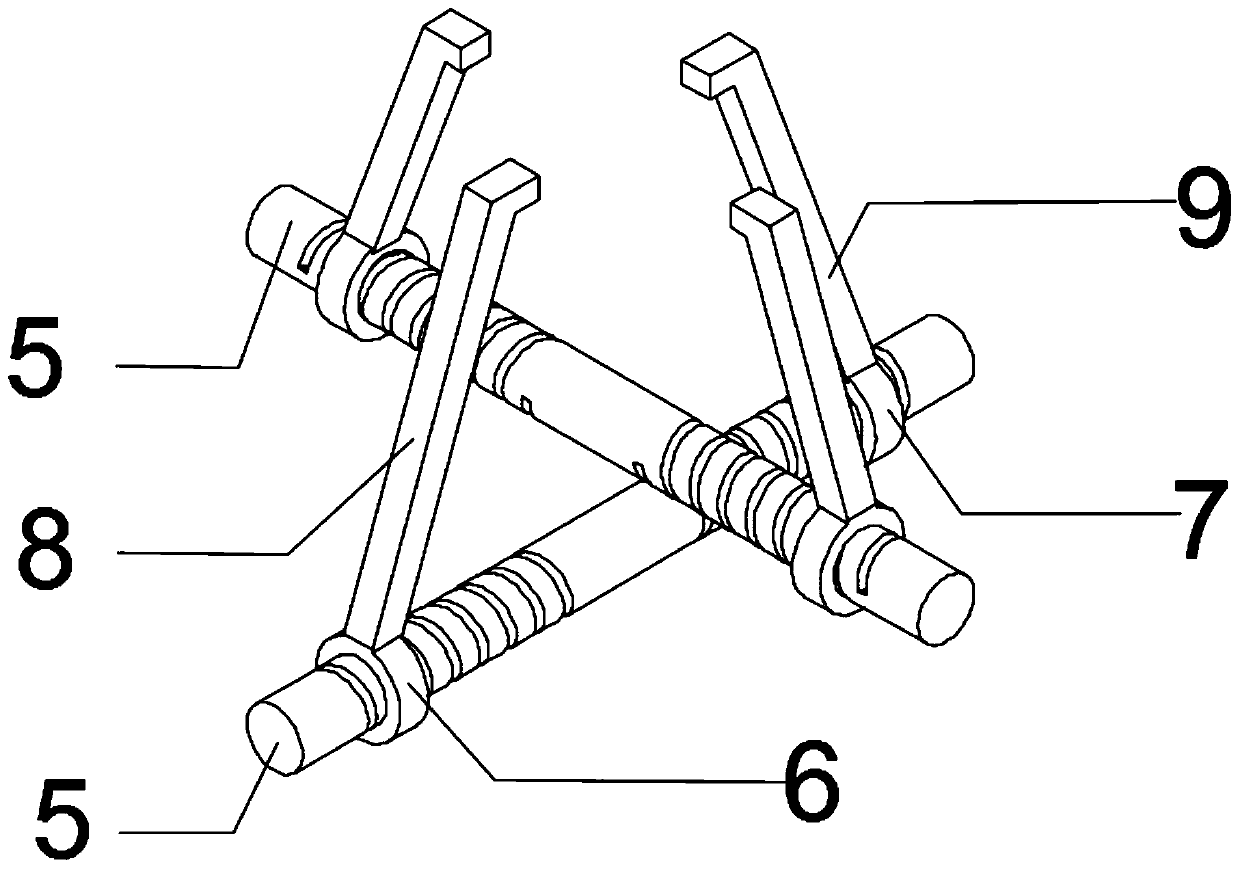

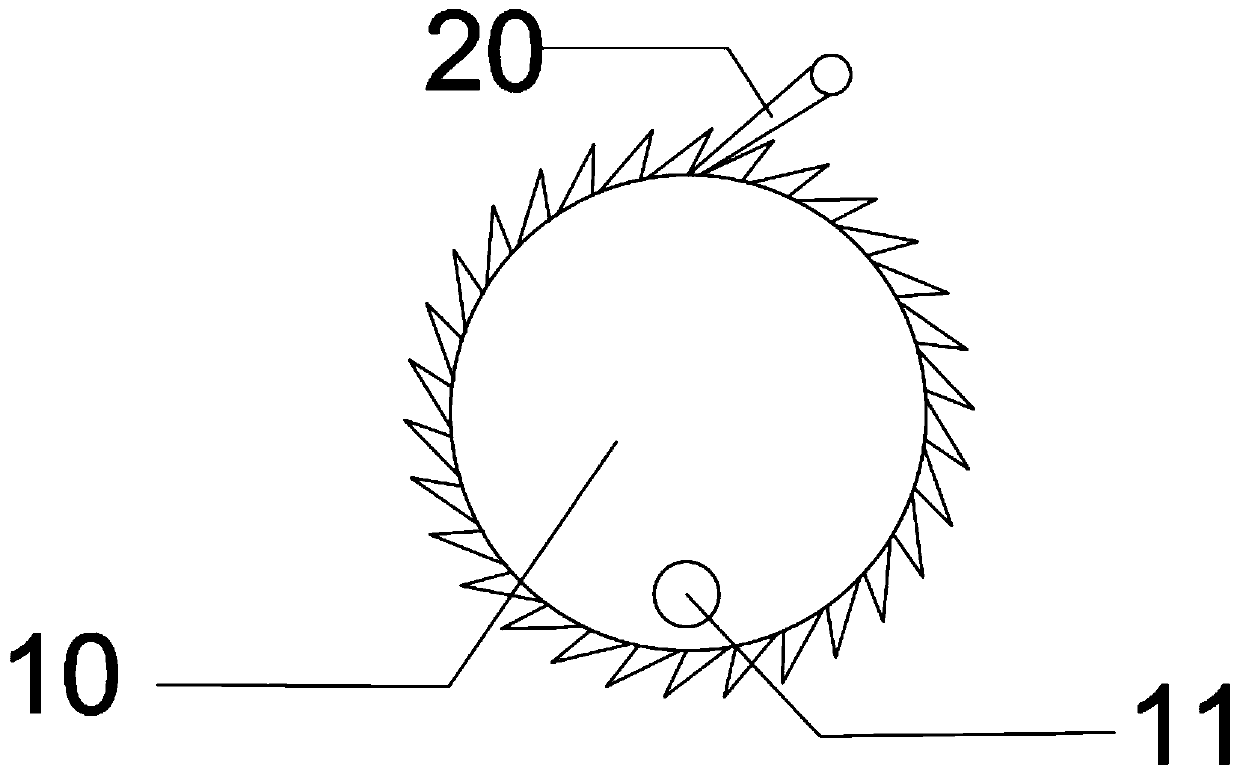

[0019] see Figure 1-3 , this embodiment provides a workbench for punching automobile parts, including a base 1, a workbench 2, a punching platform 3 and a clamping mechanism; the base 1 is provided with a workbench 2; A punching table 3 for placing automobile parts is provided; a punching device is arranged above the punching table 3; a clamping mechanism for clamping automobile parts is also provided on the punching table 3; The mechanism includes a left and right clamping mechanism and a front and rear clamping mechanism; the left and right clamping mechanism and the front and rear clamping mechanism have the same structure, and the two are vertically arranged, respectively located on the left and right sides and the front and rear sides of the auto parts; the left and right clamping mechanisms It includes a clamping rod 5, a left sleeve 6, a right sleeve 7, a left sliding rod 8, a right sliding rod 9, a rotating wheel 10 and a rotating handle 11; On the rotating wheel 10;...

Embodiment 2

[0027] This embodiment is further improved on the basis of Embodiment 1. The improvements are: in order to keep the worktable 2 more stable during the lifting process, a limit mechanism is also set between the worktable 2 and the base 1; The positioning mechanism includes an inner sliding rod 17, an outer fixing sleeve 18 and a spring 19; the bottom of the table 2 is fixed with the upper end of the inner sliding rod 17; the lower end of the inner sliding rod 17 is slidably arranged on the outer fixing sleeve through the spring 19 18; the outer fixing sleeve 18 is also provided with a limit block to prevent the inner sliding rod 17 from being detached; the bottom of the outer fixing sleeve 18 is fixed on the base 1, so that when the worktable 2 is raised and lowered , under the action of the inner sliding rod 17 , the outer fixing sleeve 18 and the spring 19 , the lifting and lowering is more stable.

[0028] In order to further maintain the stability of the worktable 2 during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com