Air bearing spindle rotation error detection and compensation device and method based on reflection principle

A technology of air-floating spindle and rotation error, which is applied in the detection and compensation of air-floating spindle rotation error and the field of air-floating spindle rotary motion error compensation device, which can solve the problems that the loading force cannot be accurately guaranteed and the detection error compensation cannot be realized. , to achieve the effect of easy detection, accurate compensation and gentle compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

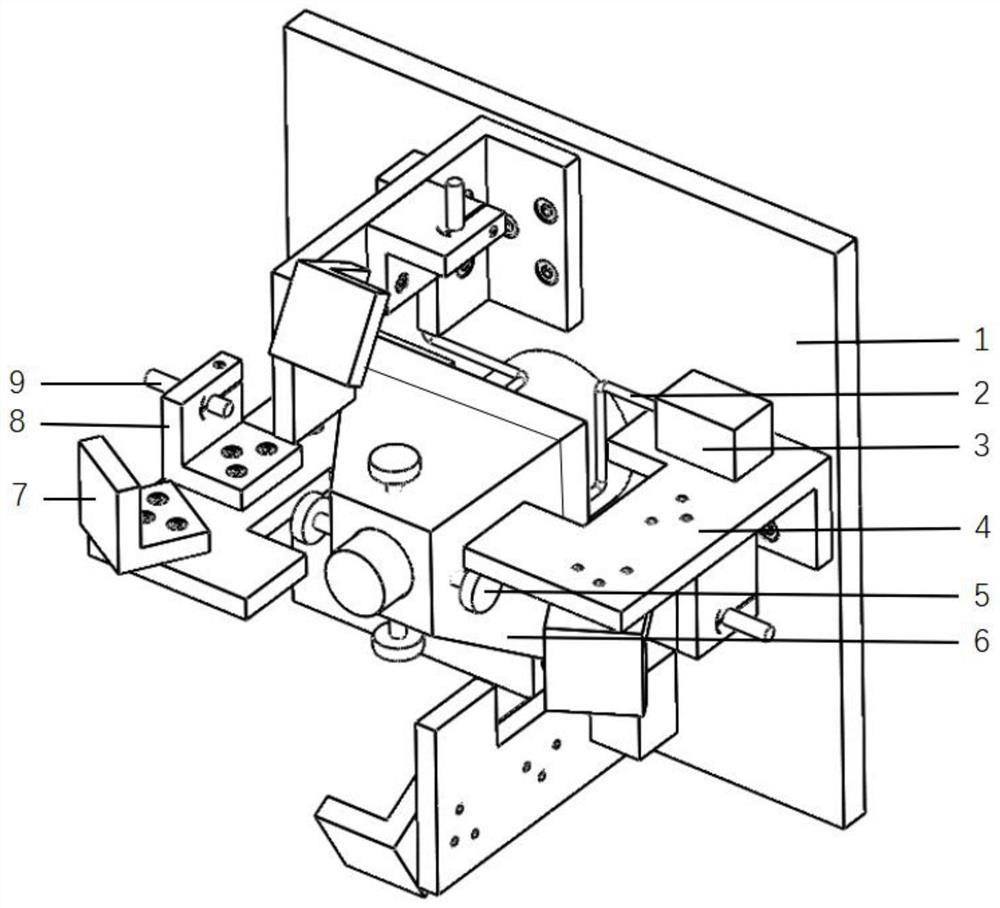

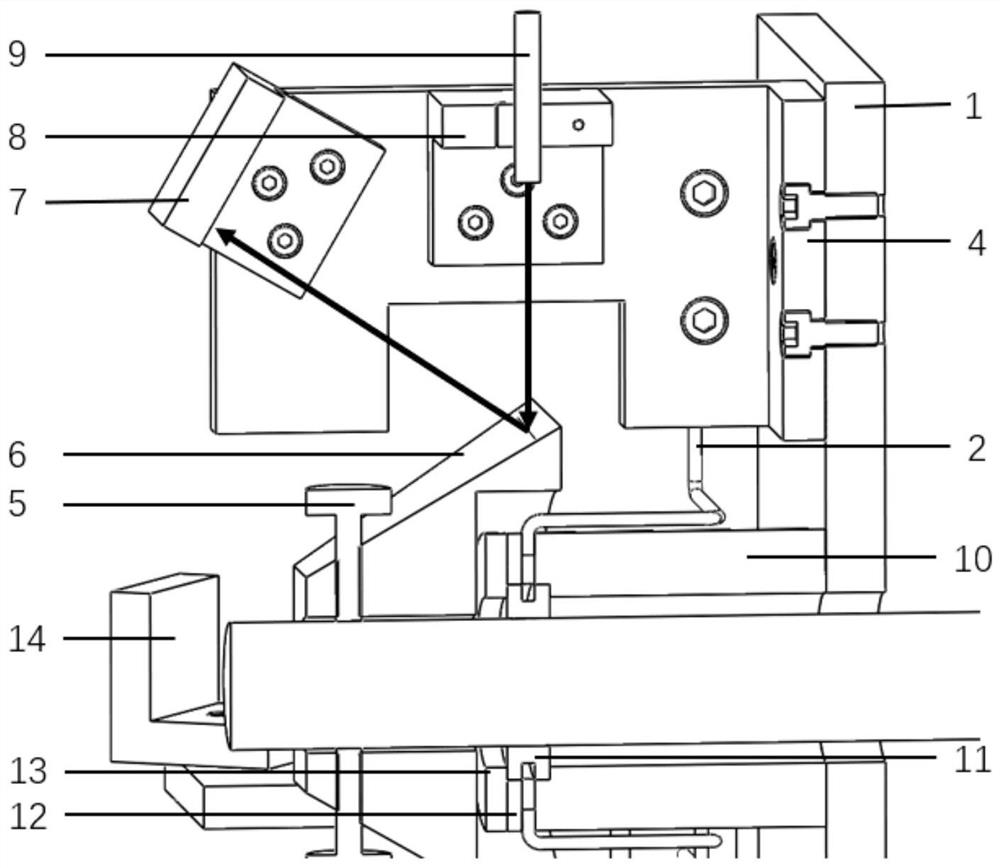

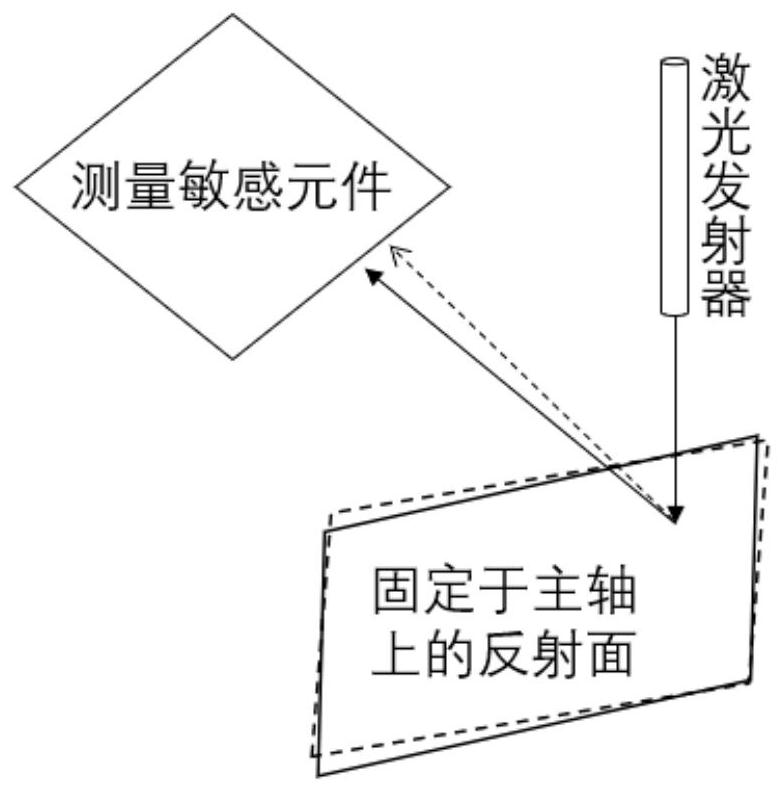

[0033] Such as figure 1 , figure 2 with Figure 5As shown, the main shaft rotary motion error detection and compensation device based on the reflection principle includes a device fixing plate 1, a vent pipe 2, an intake pressure control valve 3, a measuring device fixing bracket 4, an alignment knob 5, an auxiliary measurement reflection table 6, Measurement sensitive element installation base 7, laser transmitter installation base 8, laser transmitter 9, bearing fixing sleeve 10, radial air bearing 11 and measurement sensitive element 14; holes; the installation plane of the device fixing plate 1 is also provided with n through holes uniformly distributed along the circumferential direction of the main shaft through hole and n threaded hole groups uniformly distributed along the circumferential direction of the main shaft through hole, and the diameter of the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com