Automatic rotating car washing device

A technology for automatic rotation and car washing, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of high repetition of actions, laborious and time-consuming cleaning work, low efficiency, etc., and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in further non-limiting detail below in conjunction with the embodiments and accompanying drawings.

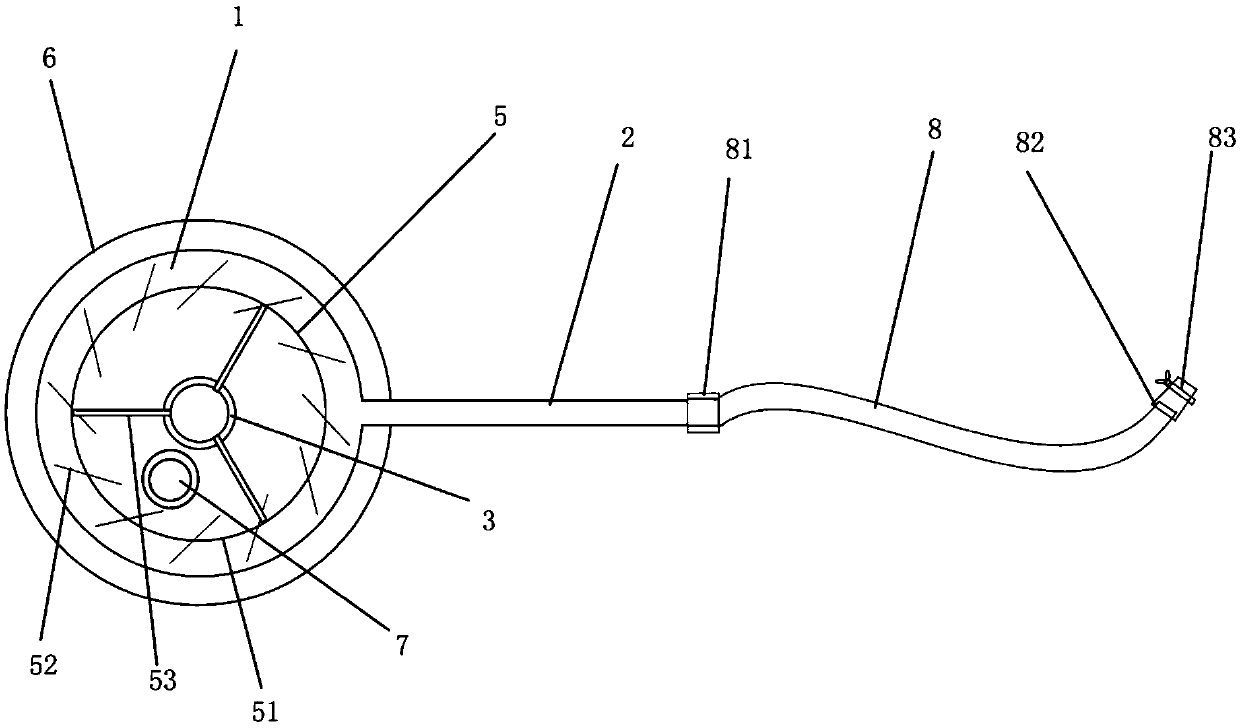

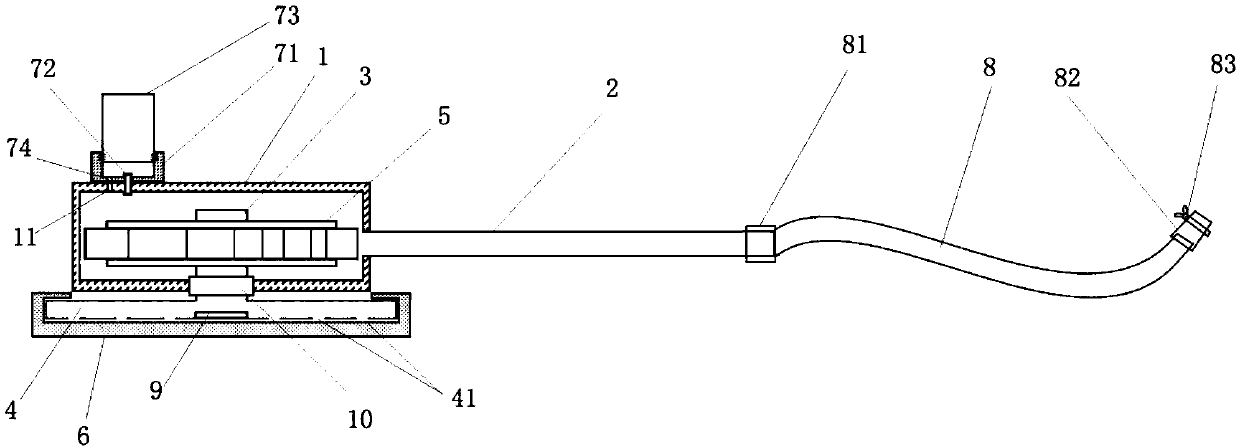

[0015] Such as figure 1 and 2 As shown, the automatic rotating car washing device includes a shell 1, a hollow handle 2, a rotating cylinder 3, a turntable 4, a water wheel 5, a cleaning cover 6, a permanent magnet 9, a car washing liquid tank 7 and a hose 8; the inside of the shell 1 and the hollow handle One end of 3 is connected, and the hollow handle can be used as a handle or as a water pipe; the rotating cylinder 3 is rotatably installed on the bottom of the casing 1 through the bearing 10, and the upper end of the rotating cylinder 3 extends into the casing 1 and is connected with the water The central axis of the wheel 5 is fixed, the lower end of the drum 3 protrudes from the outer shell 1, and is fixed with the central axis of the turntable 4, the shell 1 communicates with the inside of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com