Underground coal mine conveying device

A technology for conveying devices and coal mines, applied in transportation and packaging, multi-axis trolleys, trolleys, etc., can solve problems such as poor user experience, poor applicability of transportation devices, complex underground environment, etc., to improve applicability, avoid interference, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

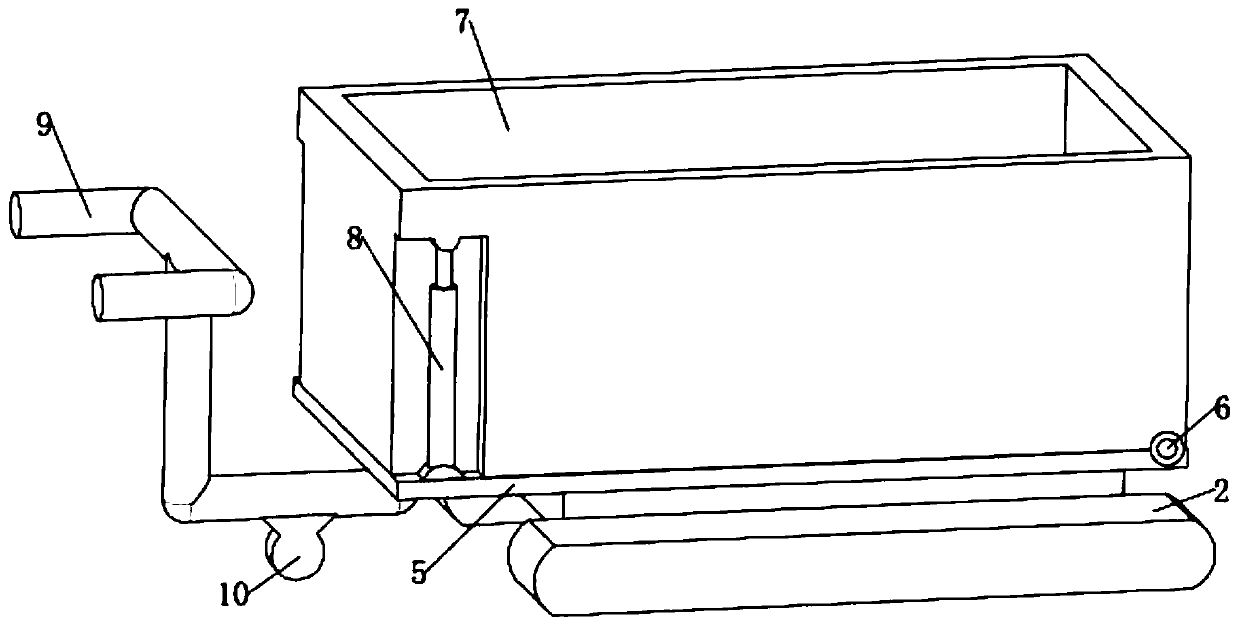

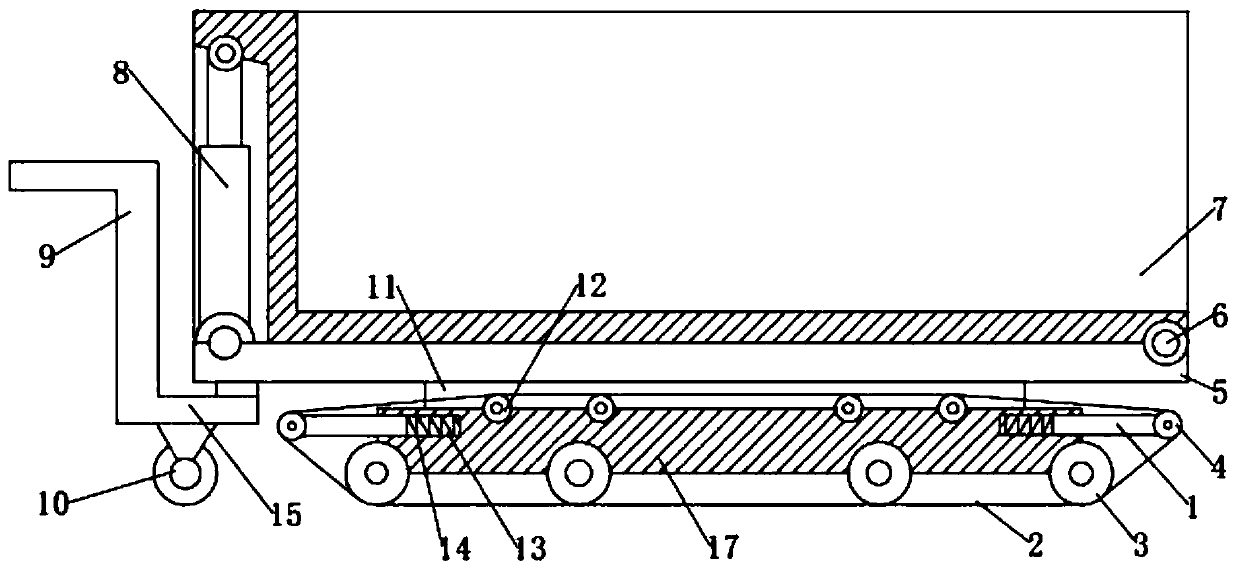

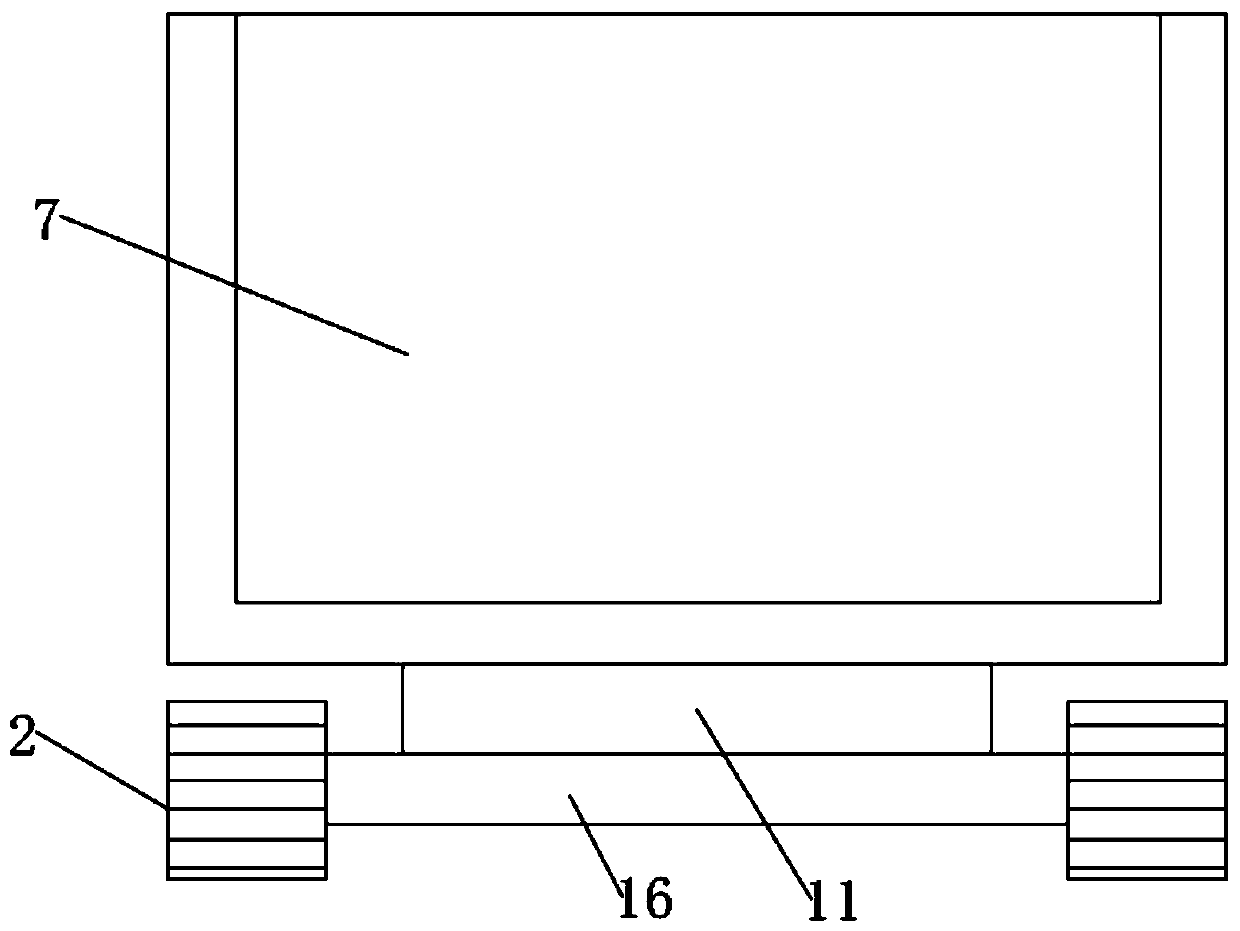

[0020] see Figure 1-3 , a coal mine underground conveying device, comprising a bearing box 7, a base plate 5, a main shaft support 17, a bearing support 11, a main shaft 16 and crawler belts 2, wherein the base plate 5 is fixedly mounted on the bearing support 11, and the main shaft support 17 The two ends of the bearing bracket 11 are fixedly installed, and the driving wheel 3 is rotatably installed on the main shaft bracket 17. The specific number of the driving wheel 3 is not limited. In this embodiment, preferably, the driving wheel 3 Four wheels 3 are equidistantly arranged on the main shaft bracket 17. The main shaft 16 is rotatably mounted on the driving wheel 3, and the driving device is fixedly installed on the main shaft 16, and the driving device is further driven by the driving device. The driving wheel 3 rotates, and the crawler belt 2 is expanded and installed on the outside of the driving wheel 3, and then when the driving wheel 3 rotates, the rotation of the c...

Embodiment 2

[0028] In order to make the crawler belt 2 of the device more stable when rotating, the present embodiment makes the following improvements on the basis of the first embodiment. The improvement is that the main shaft support 17 is rotatably mounted with several adjustment wheels 12 The adjustment wheel 12 is arranged above the main shaft support 17, and the interference between the crawler belt 2 and the main shaft support 17 is effectively avoided by the adjustment wheel 12.

[0029] The working principle of this embodiment: by rotating and installing several adjusting wheels 12 on the main shaft support 17 , the interference between the caterpillar belt 2 and the main shaft support 17 is avoided through the adjustment wheels 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com