Wrapping system of chinlon hemp grey yarn and preparing technology of chinlon hemp grey yarn

A nylon and hemp ash technology is applied to the covering system of nylon hemp ash yarn and its preparation technology, which can solve the problems of wrinkling, different patterns/types, short silk paths, etc., and achieves the effects of uniform color eating and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

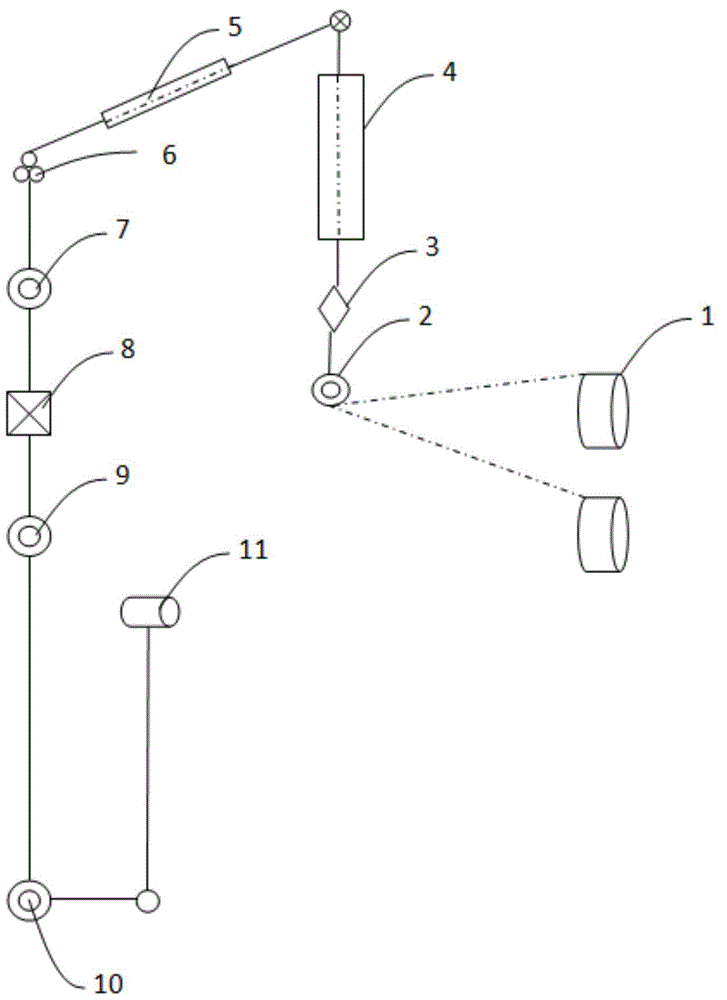

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0033] DTY: Drawtexturingyarn stretch textured yarn. Also known as polyester low elastic yarn, it is the finished yarn after continuous or simultaneous stretching and deformation processing on one machine.

[0034] FDY: Fullydrawnyarn fully drawn yarn. It has nothing to do with the production process, but it is widely spread now. It is used as the code name of the one-step spinning and drawing process. It can use low-speed spinning and high-speed drawing and winding. The two processes are completed on one spinning and drawing machine. , The production cost of this production line is low, and the quality of the finished product is stable, the wool yarn breakage is less, and the dyeing uniformity is good. DTY fibers are curly and FDY fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com