Transportation equipment for raw material conveying at wharf

A technology for transporting equipment and raw materials, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as material loss and blow-off, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

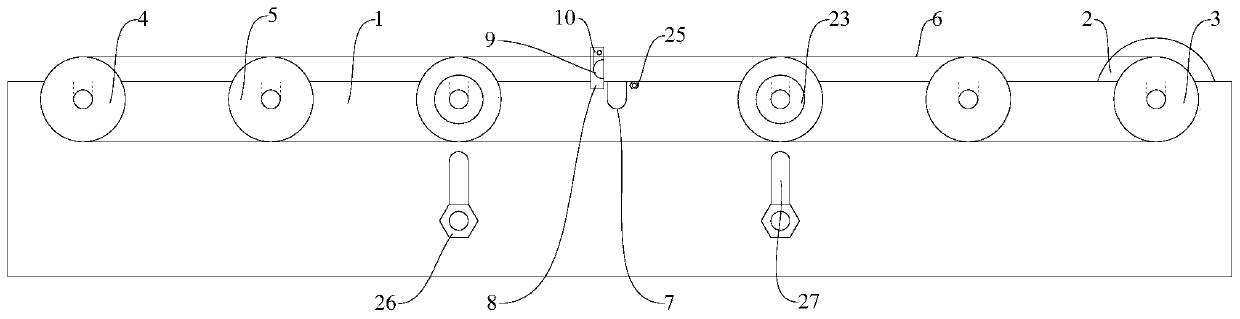

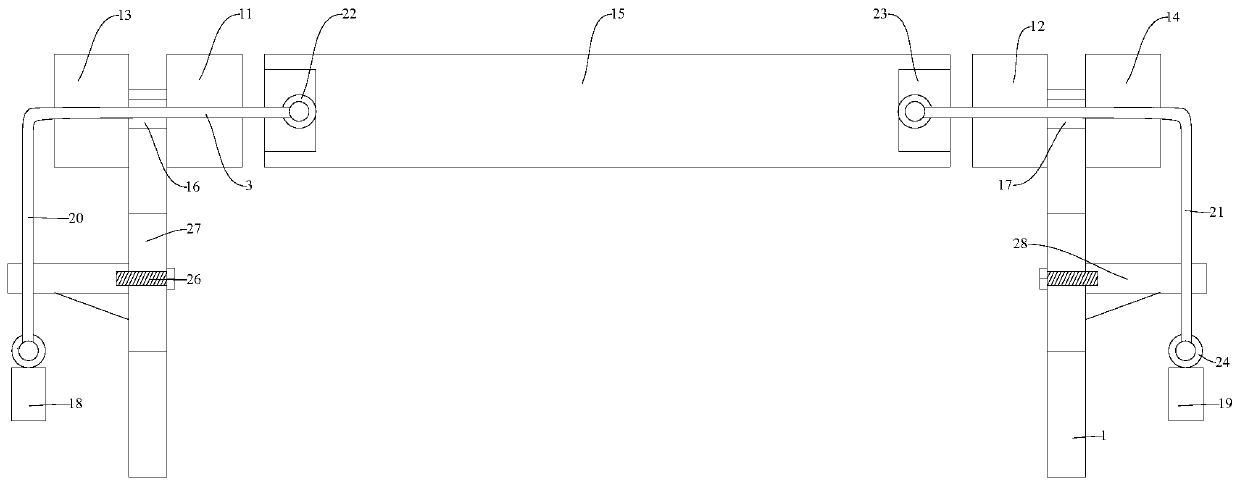

[0015] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0016] figure 1 with figure 2 The transportation equipment shown for the transportation of raw materials at the wharf includes a fixed bracket 1, a driving motor 2, a driving roller 3, a driven roller 4, and a supporting roller 5 axially fixed on the shaft of the driving motor 2 installed on the ground. And the conveyor belt 6 sleeved on the driving roller 3, the driven roller 4 and the supporting roller 5. The upper surface of the fixed bracket 1 is provided with 7 top assembly grooves 7 with upper ends, and the upper surface of the fixed bracket 1 is located on the side of the top assembly groove 7 The top flip cover 8 is movably connected by a lateral rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com