A method for horizontally segmented assembly of a multi-stage rocket

An assembly method and a level technology, applied in the direction of lifting devices, reducing greenhouse gases, climate sustainability, etc., can solve the problems of hoisting links are easily affected by wind, low degree of standardization and automation, time-consuming operation process, etc., to shorten the launch time. The effect of preparation time, increased automation, and reduced time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

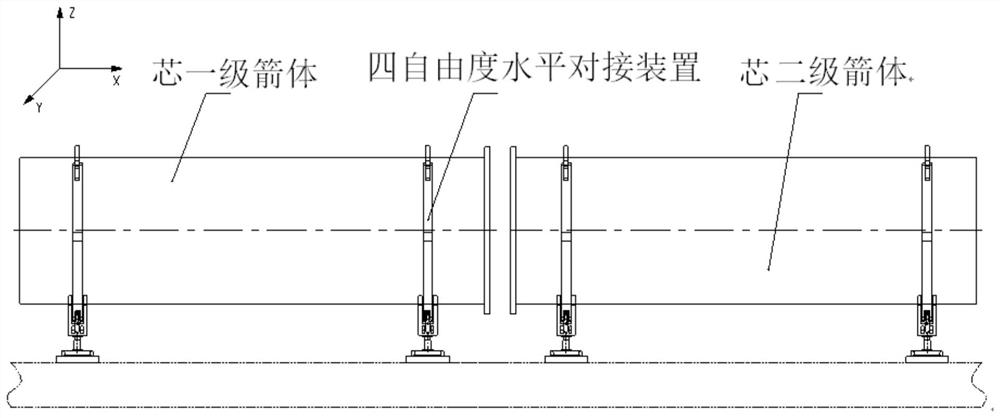

[0030] as attached figure 2 As shown, the rocket to be assembled in the embodiment is composed of two segments, a core-level one and a core-level two, and the transport support vehicle includes a core-level transport support vehicle.

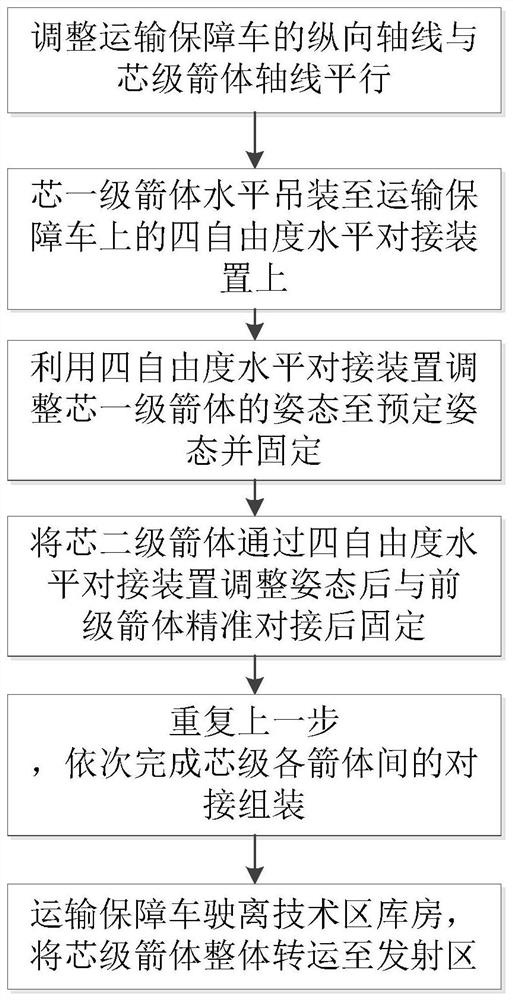

[0031] The invention provides a method for assembling a multi-stage rocket horizontally and segmented, as shown in the attached figure 1 As shown, the implementation steps of this method are as follows:

[0032] Step 1: The core-level transportation support vehicle drives into the warehouse of the technical area, and the longitudinal axis of the vehicle is parallel to the axis of the arrow body;

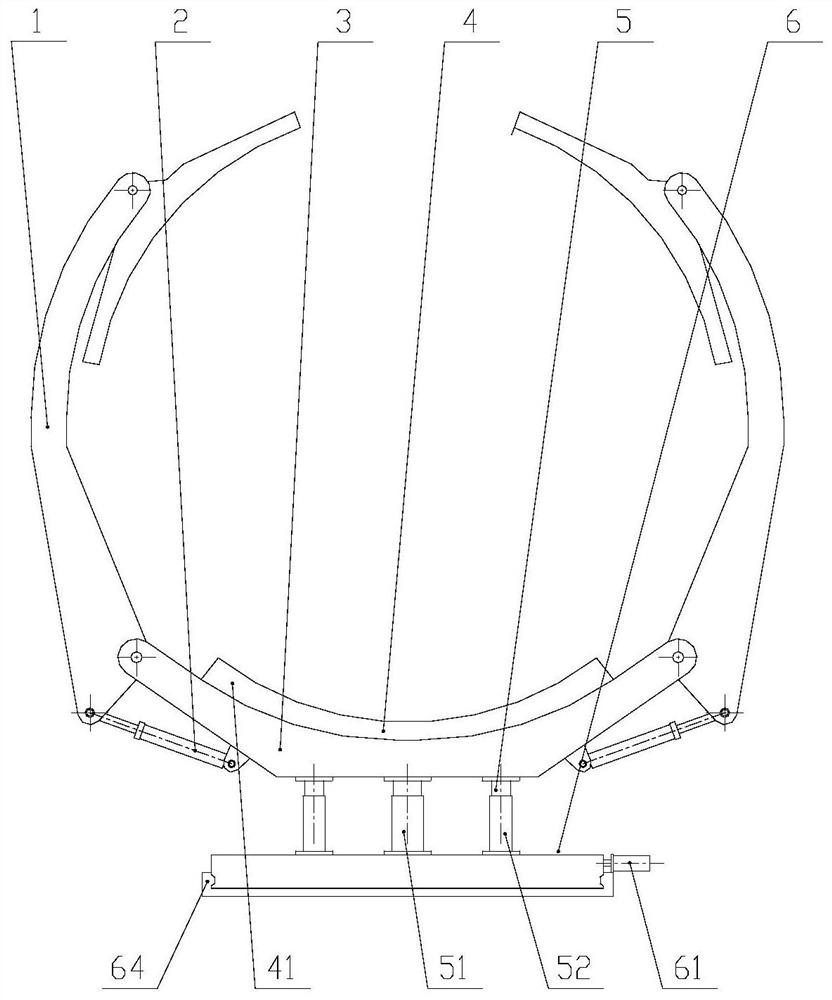

[0033] Step 2: Use the warehouse lifting equipment to horizontally hoist the core-level arrow body to the corresponding four-degree-of-freedom horizontal docking device on the core-level transportation support vehicle; the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com