Pneumatic tire

A technology for pneumatic tires and tires, which is applied to off-road vehicle tires, tire parts, tire treads/tread patterns, etc., which can solve the problems of easy damage to the bottom of the groove, cutting resistance, and easy decline in wear resistance, and achieve improved Driving performance, improved discharge performance, excellent edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

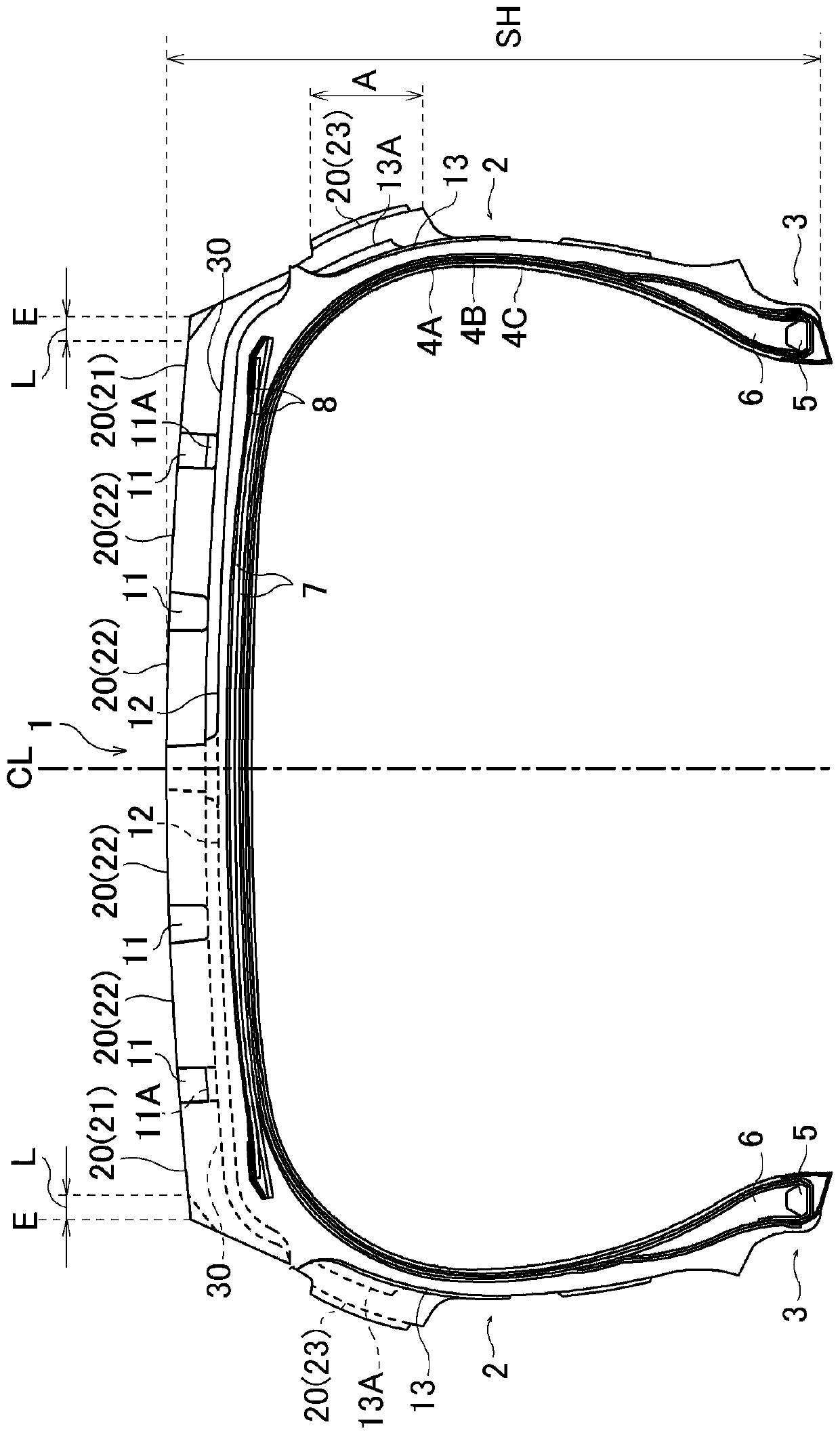

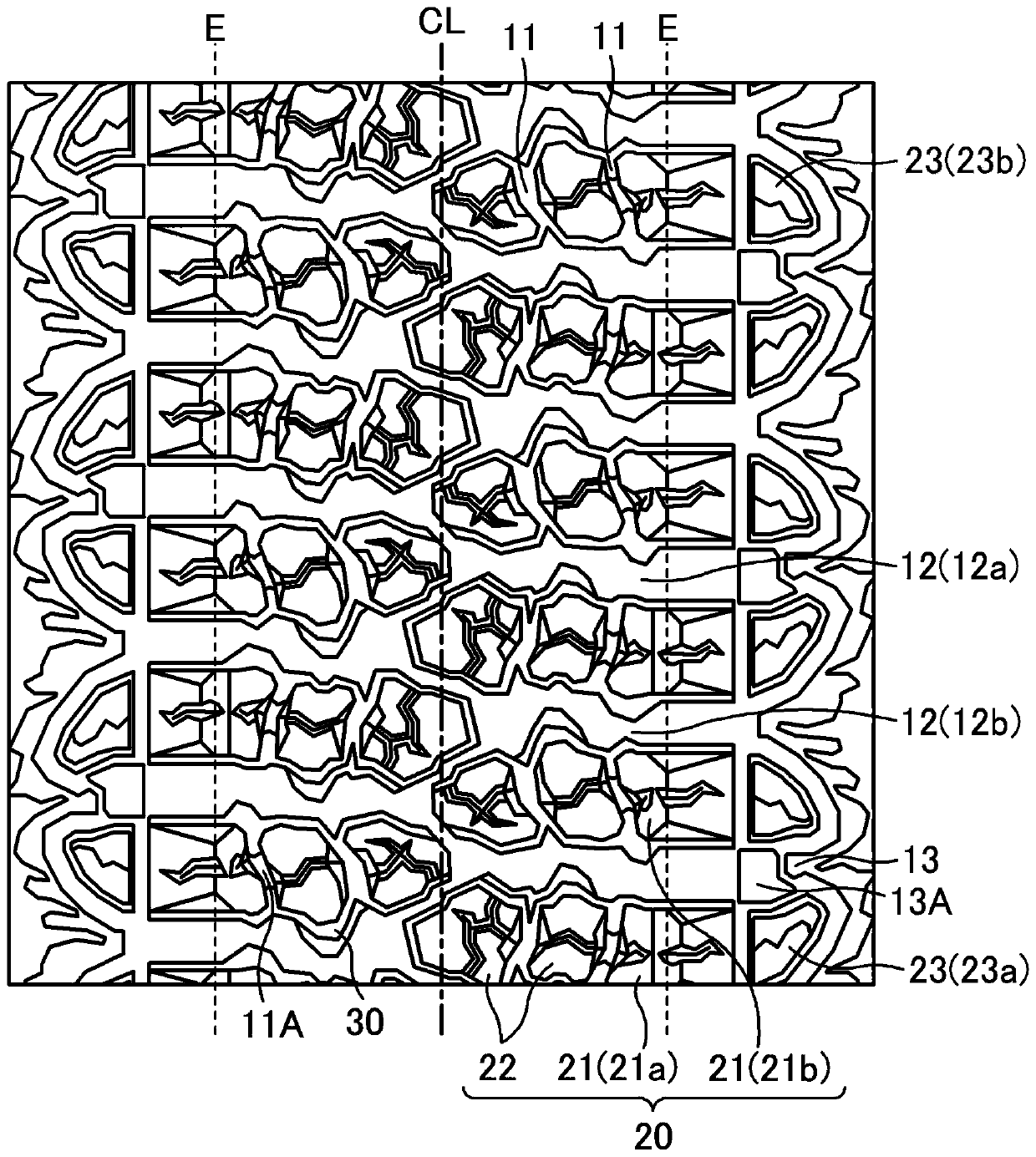

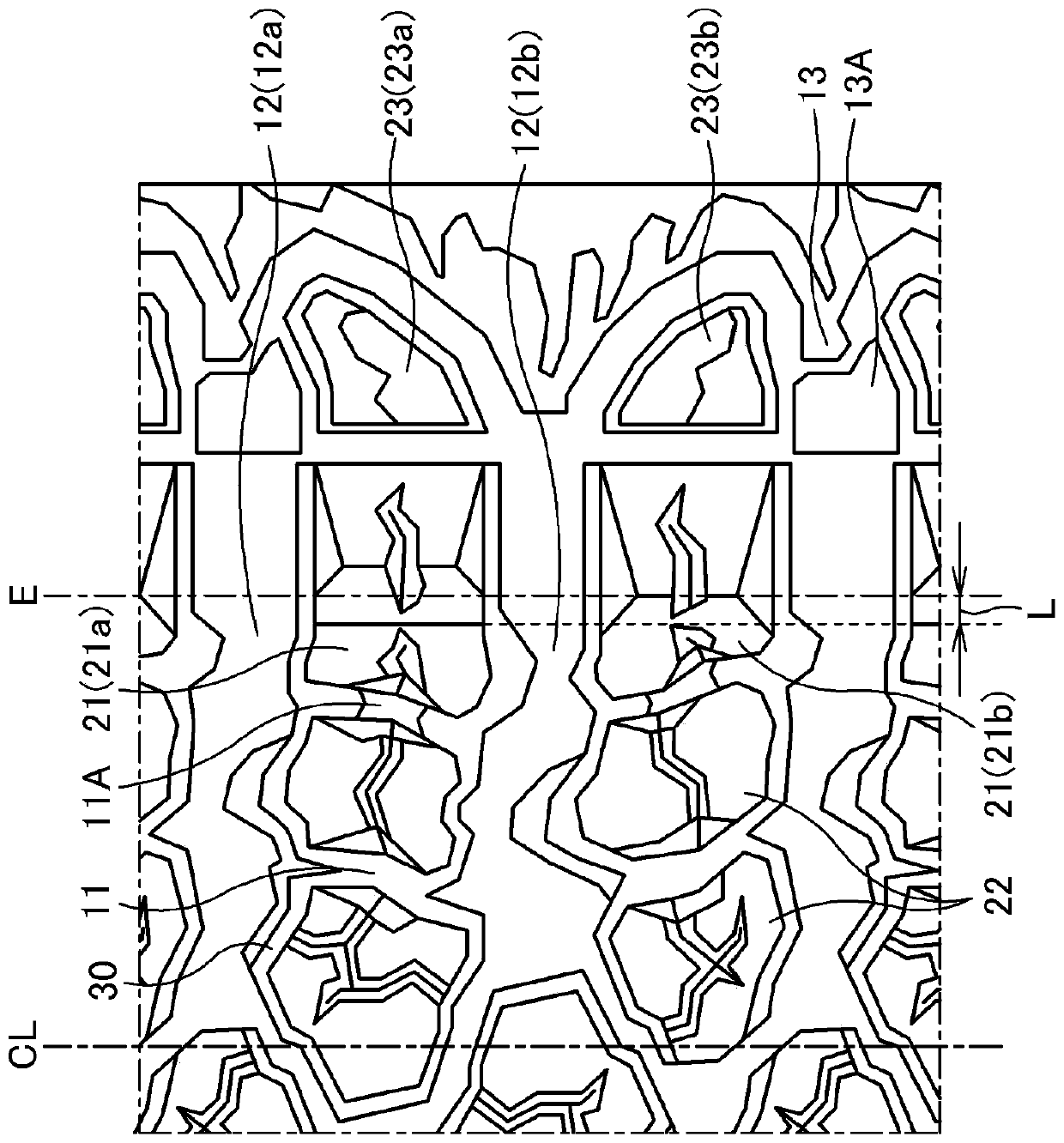

[0047] Made a tire size 35×12.50R17 with figure 1 The basic structure of the example and the figure 2 The tread pattern is the keynote and the presence or absence of wide outer blocks, the presence or absence of narrow outer blocks, the amount of entry L, the arrangement of large blocks, the arrangement of small blocks, the presence or absence of narrow width of transverse grooves, the presence or absence of transverse grooves The presence or absence of the wide part, the change in the groove width of the sidewall groove connected to the narrow part, the change in the groove width of the sidewall groove connected to the wide part, the presence or absence of the platform, and the protruding height H2 of the sidewall block , the ratio A / SH of the length A of the sidewall block measured along the tire radial direction to the tire cross-sectional height SH, and the protrusion height H3 of the bottom raised portion of the sidewall groove were set as shown in Tables 1 and 2 for com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com