Concrete pouring method adopting flexible shuttle chute

A technology of concrete and flexible grooves, which is applied in the fields of construction, building structure, and building materials processing. It can solve the problems of less recycling times, difficulty in ensuring stability, and difficulty in size adjustment. It achieves simple structure, easy promotion, and advantages. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

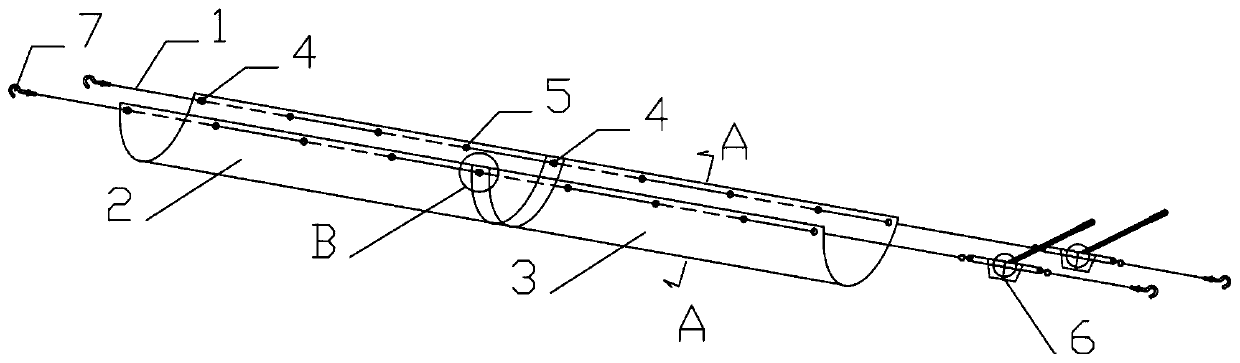

[0023] As shown in the accompanying drawings, a concrete pouring method using a flexible shuttle of the present invention comprises the following steps:

[0024] The first step is to strengthen the steel mesh or pre-embedded tie rods at the concrete pouring point, and use a concrete tanker to transport the concrete to the nearest position to the pouring point;

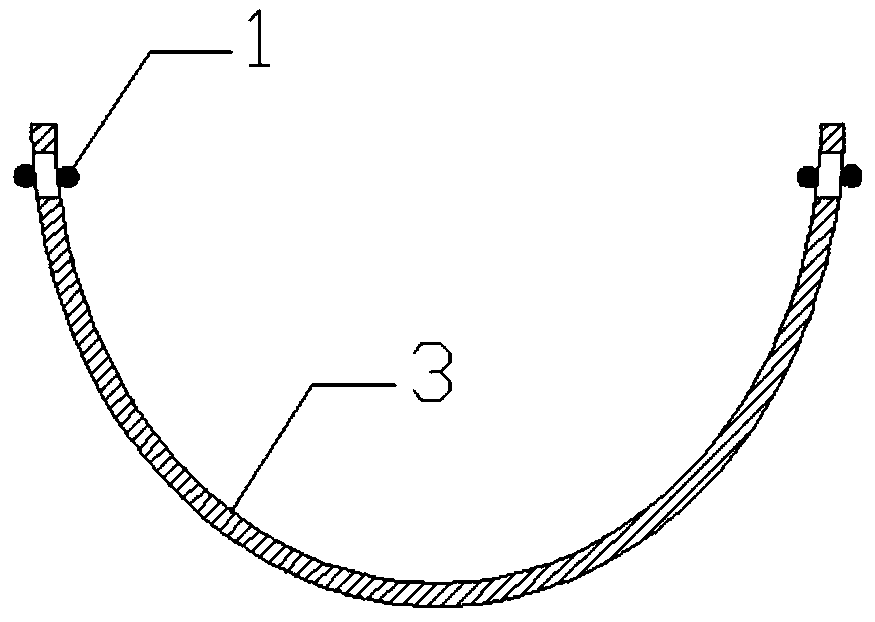

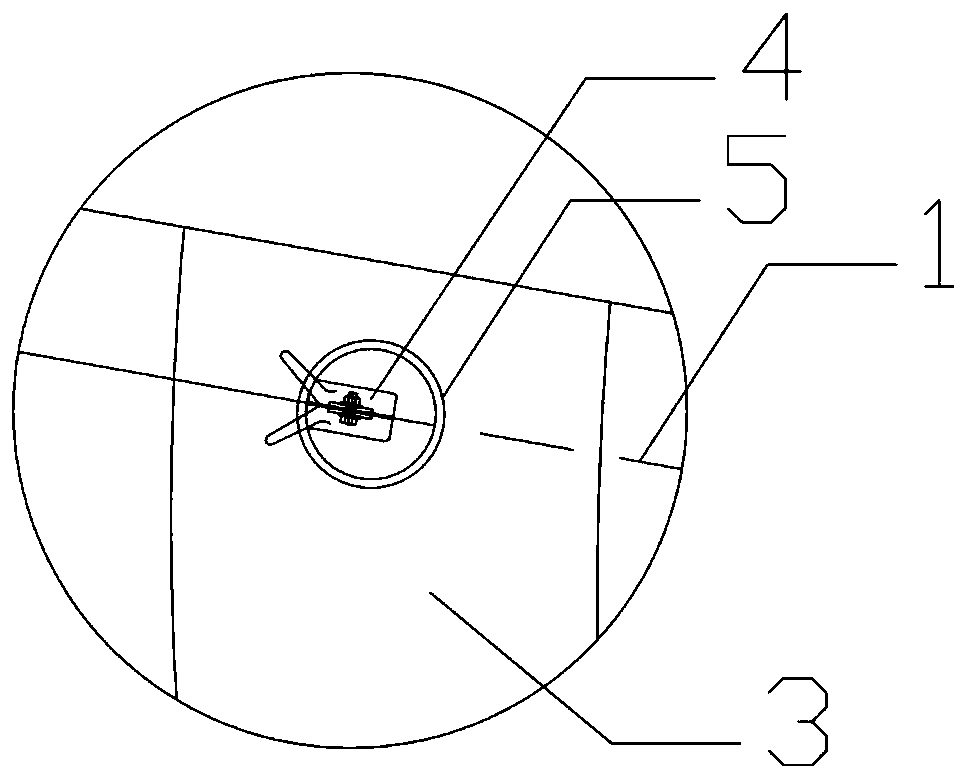

[0025] In the second step, according to the distance between the rear bumper of the concrete tank truck or the discharge hopper and the pouring point, take at least one section of rectangular flexible tank body 2, 3 and expand it for use. ring hole 5;

[0026] The third step, if the flexible tank body is one section, pass the left and right steel wire ropes through the side ring hole 5 of the matching length between the flexible tank body and the concrete pouring distance in turn, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com