Buffering gas insullation circuit breaker

A technology of gas insulation and circuit breakers, which is applied in high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of buffer type gas insulated circuit breakers such as larger volume and higher cost, and achieve overall miniaturization, electrical and mechanical advantages Effects of improved reliability and increased breaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

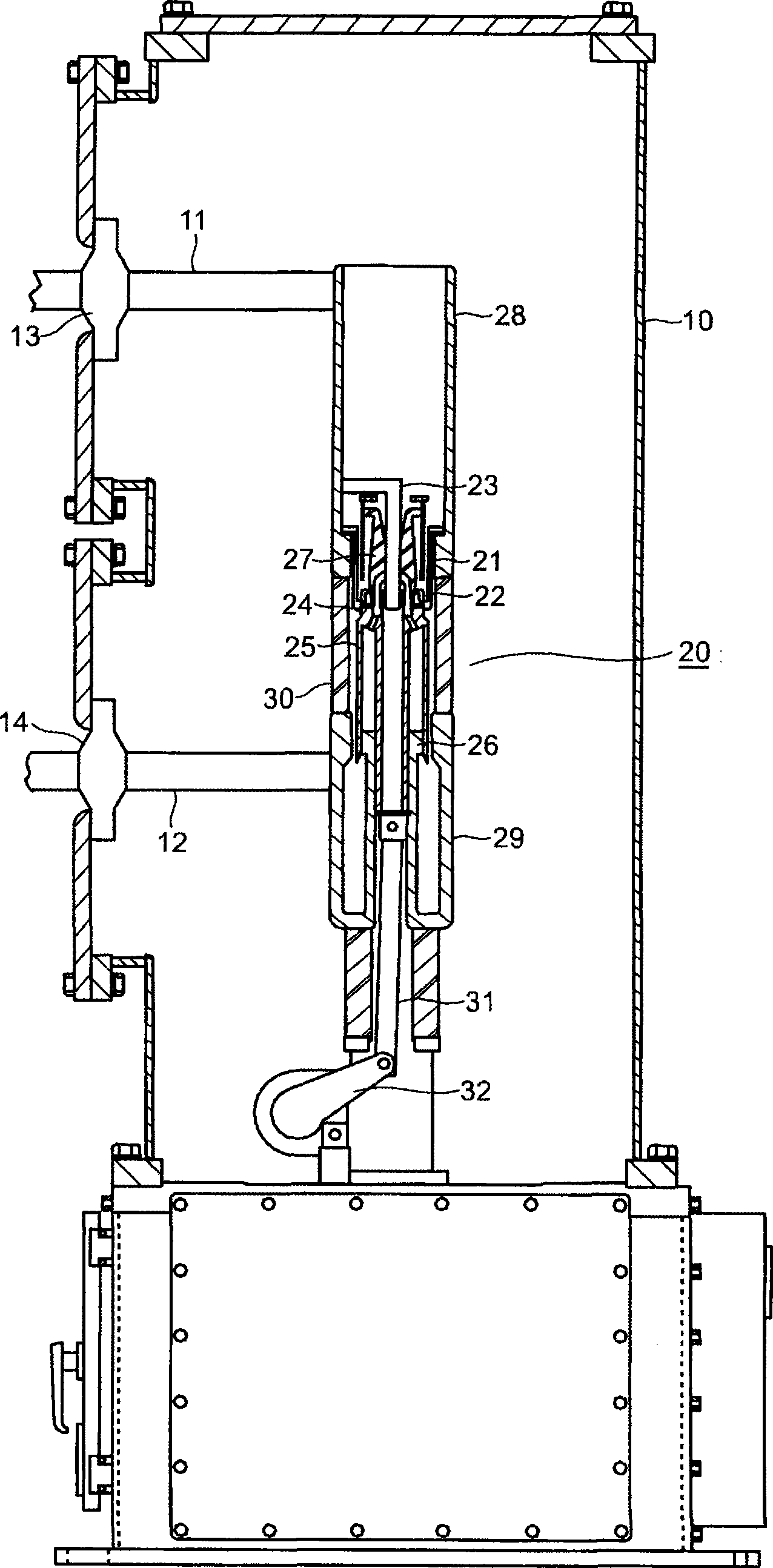

[0023] The following is an example of the application of the vertical buffer type gas insulated circuit breaker of the present invention. Figure 1 to Figure 6 Let me explain. figure 1 In the shown buffer type gas insulated circuit breaker, a circuit breaker 20 is arranged in a metal cylindrical container 10 filled with an insulating gas.

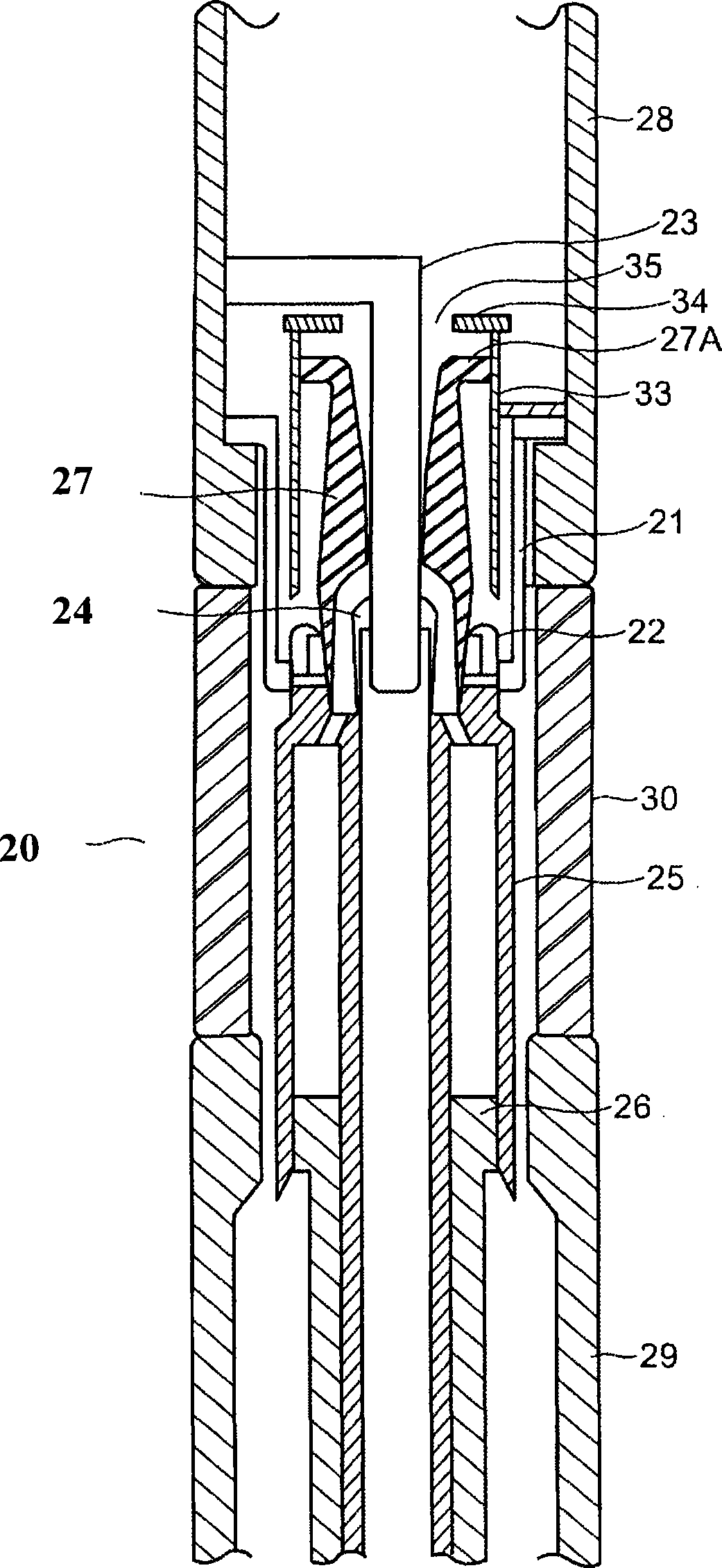

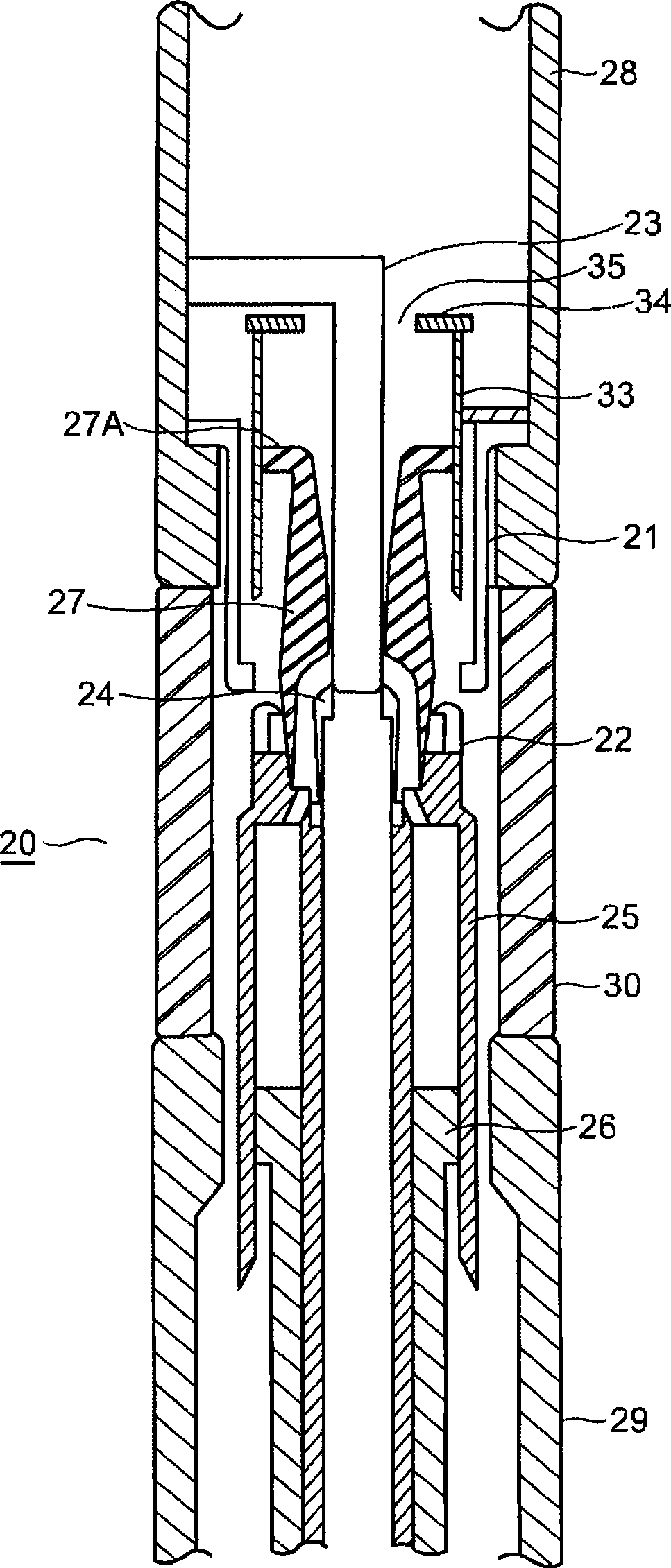

[0024] The circuit breaker 20 is composed of fixed and movable main adapters 21, 22 through which electric current flows, fixed side and movable side arc adapters 23, 24 that generate arcs during the breaking operation, and an insulating nozzle provided with 27 buffer cylinder 25 and piston 26 constitute the buffer device, etc., provided in the fixed side and the movable side cylindrical conductors 28, 29 facing each other and the inside of the insulating tube 30 interposed therebetween.

[0025] The buffer cylinder 25 of the buffer device is connected with the operator (not shown) through an insulating rod 31 and a lever 32 . When the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com