Flexible circuit board smoothing mechanism

A technology of flexible circuit boards and elastic parts, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of FPC warping and other problems, and achieve the effect of avoiding alignment accuracy that does not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

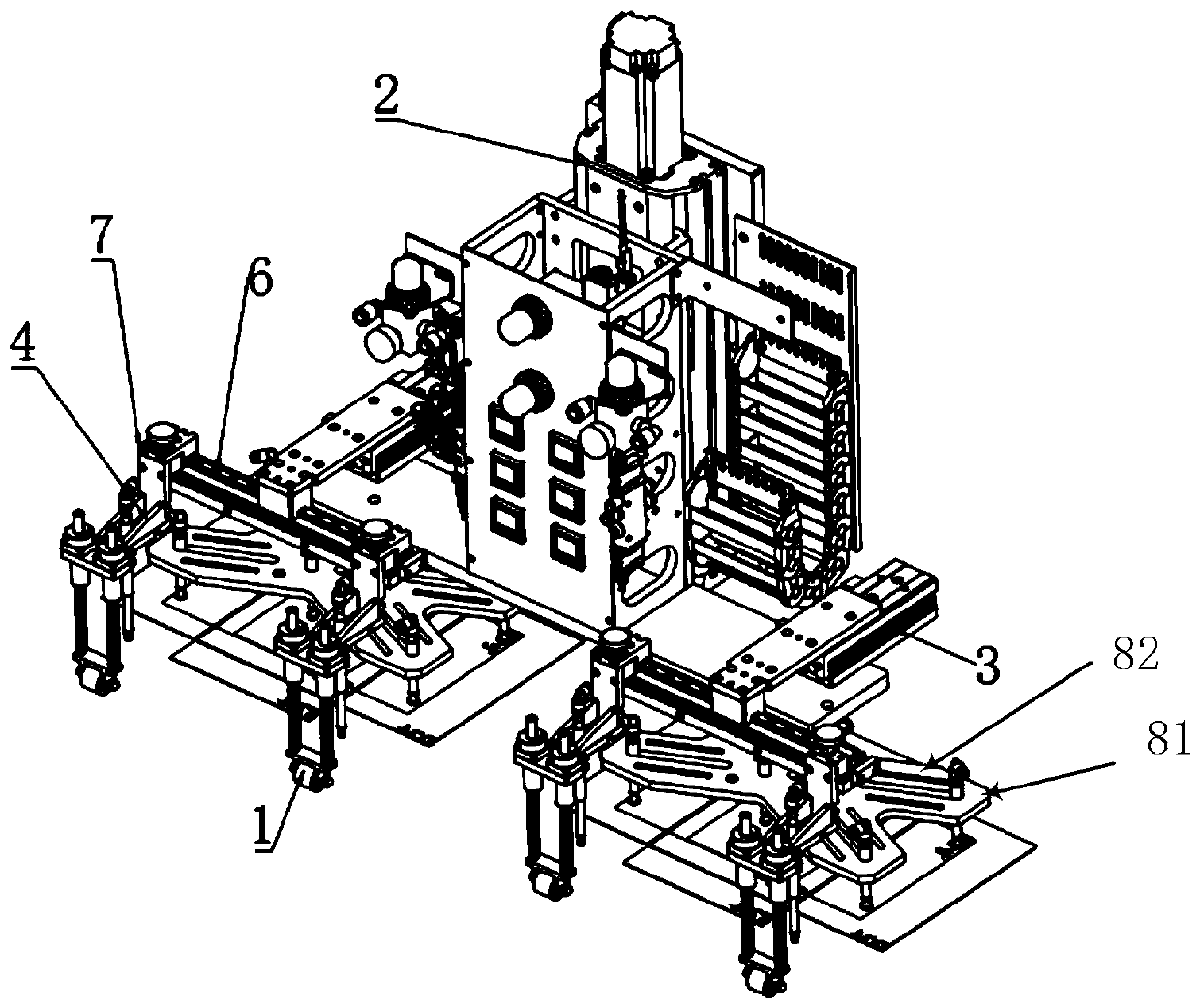

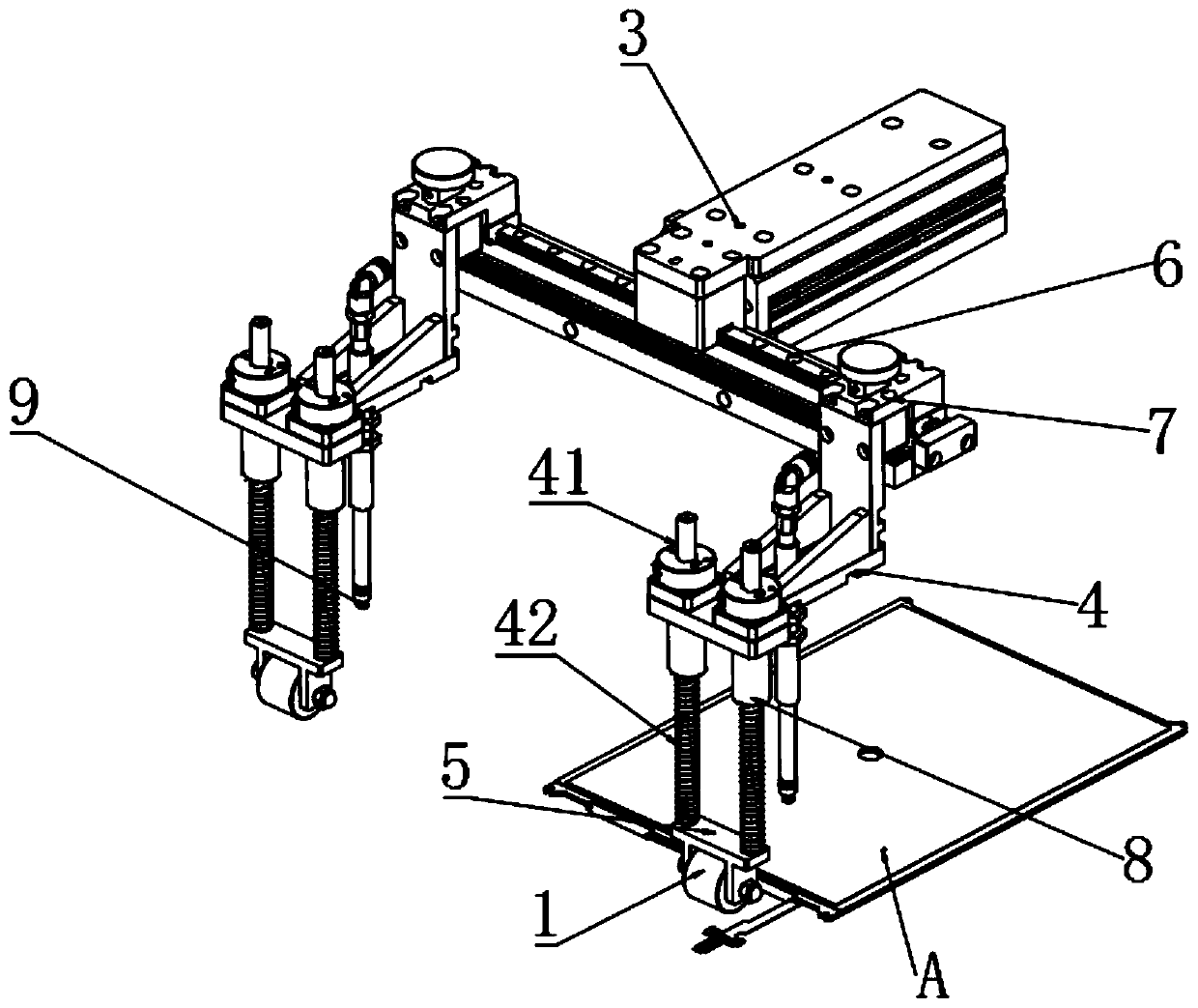

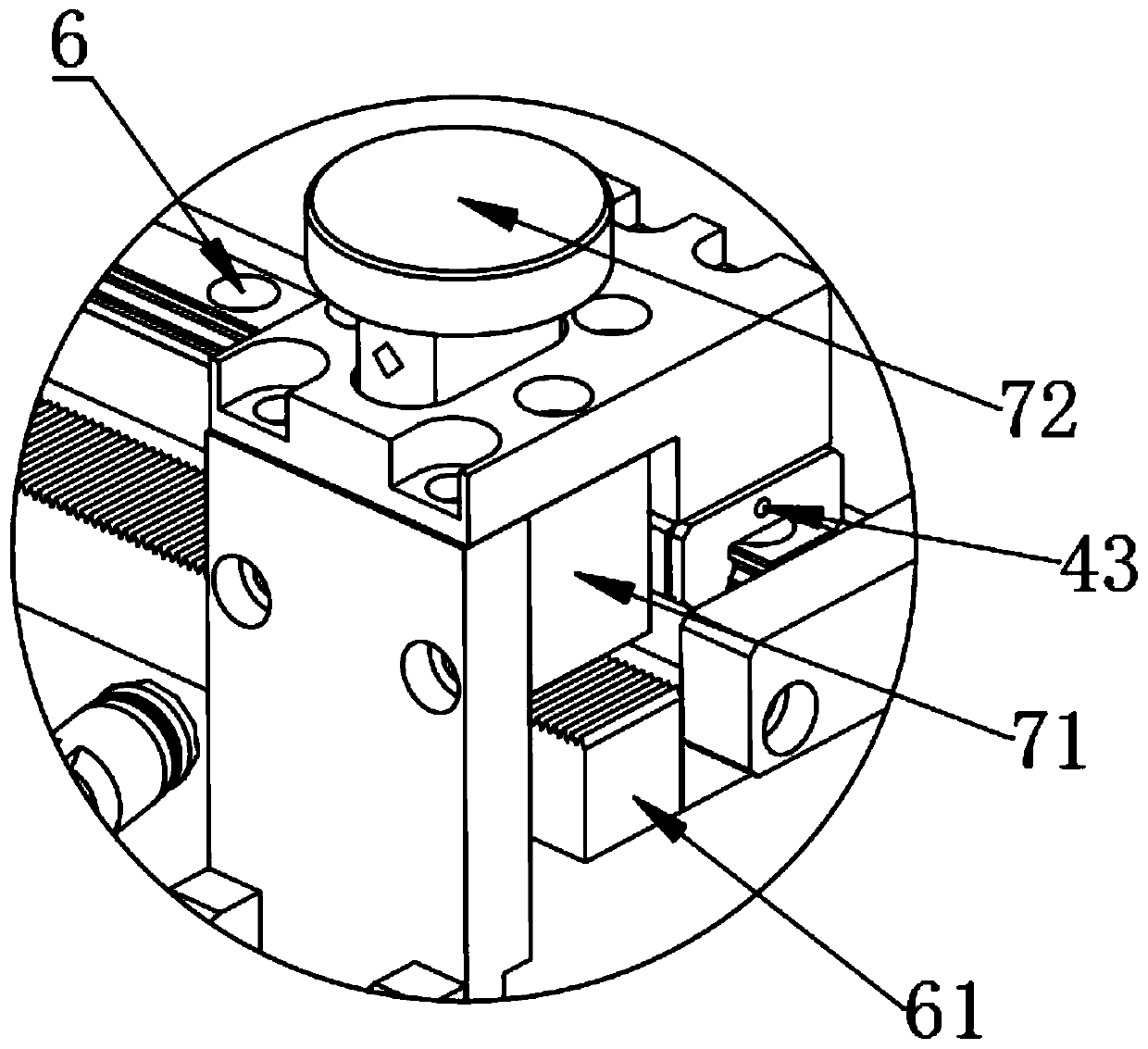

[0051] This embodiment provides a flexible circuit board smoothing mechanism, such as figure 1 shown, including:

[0052] scroll wheel 1;

[0053] The first moving component 2 is used to drive the roller 1 to approach to press the flexible circuit board or move away to break away from the contact with the flexible circuit board;

[0054] The second moving assembly 3 is used to drive the roller 1 to roll along the surface of the flexible circuit board.

[0055] The flexible circuit board smoothing mechanism of this embodiment is used as follows: first, the first moving component 2 drives the roller 1 to press on the flexible circuit board, and then the second moving component 3 drives the roller 1 to roll back and forth along the surface of the flexible circuit board, Until the flexible circuit board is flat, so that the alignment of the flexible circuit board in the subsequent process is accurate. Specifically, the flexible circuit board is placed horizontally, the first mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap