Tooling fixture for a vibration test bench

A vibration test bench and vibration test technology, which is applied in vibration test, measuring device, machine/structural component test, etc., to achieve the effects of flexible clamping, shortened selection time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

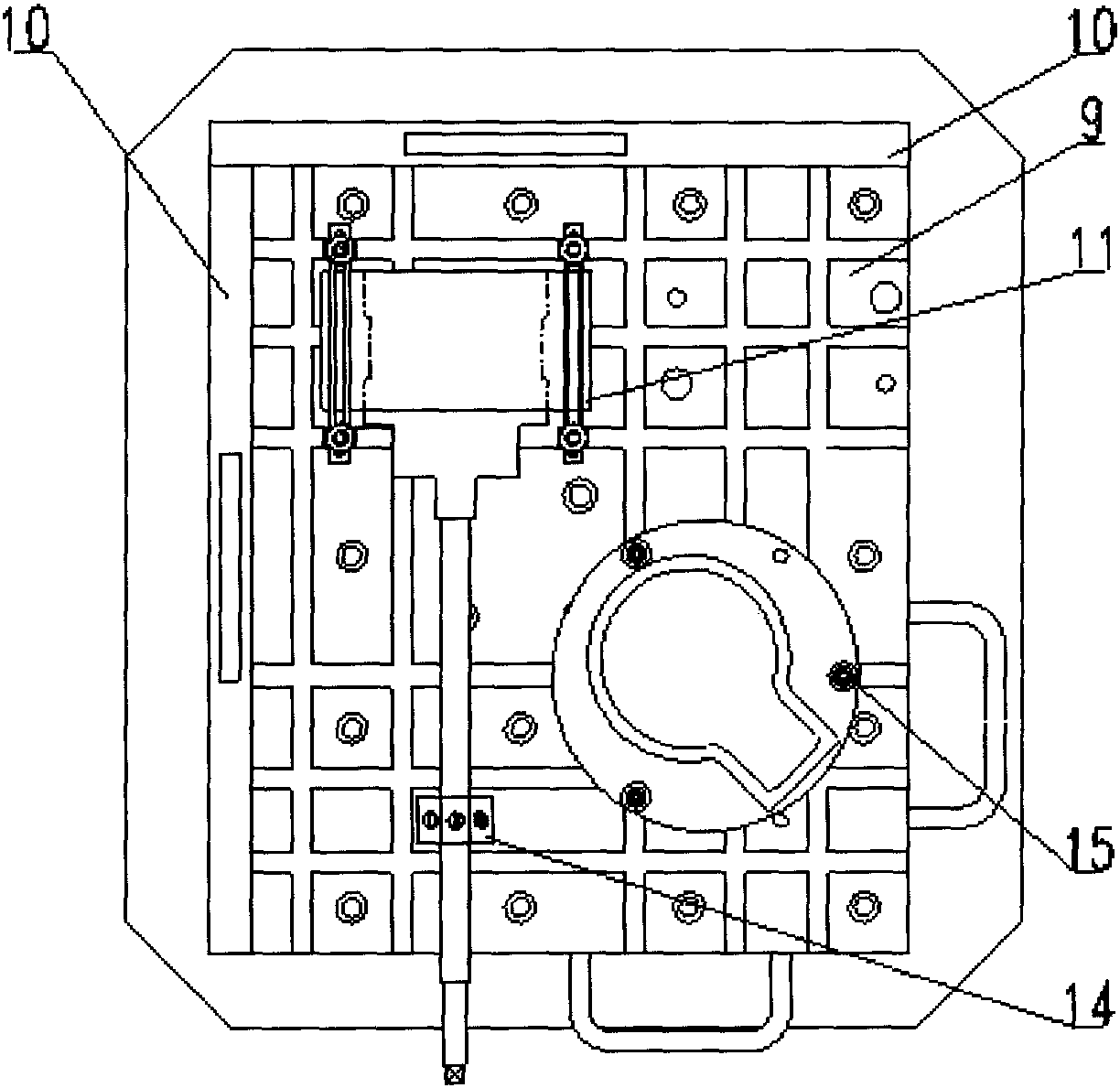

[0013] The tooling fixture for a vibration test bench of the present invention is composed of two parts: a cable vibration tooling and a box-type cylinder-type vibration tooling;

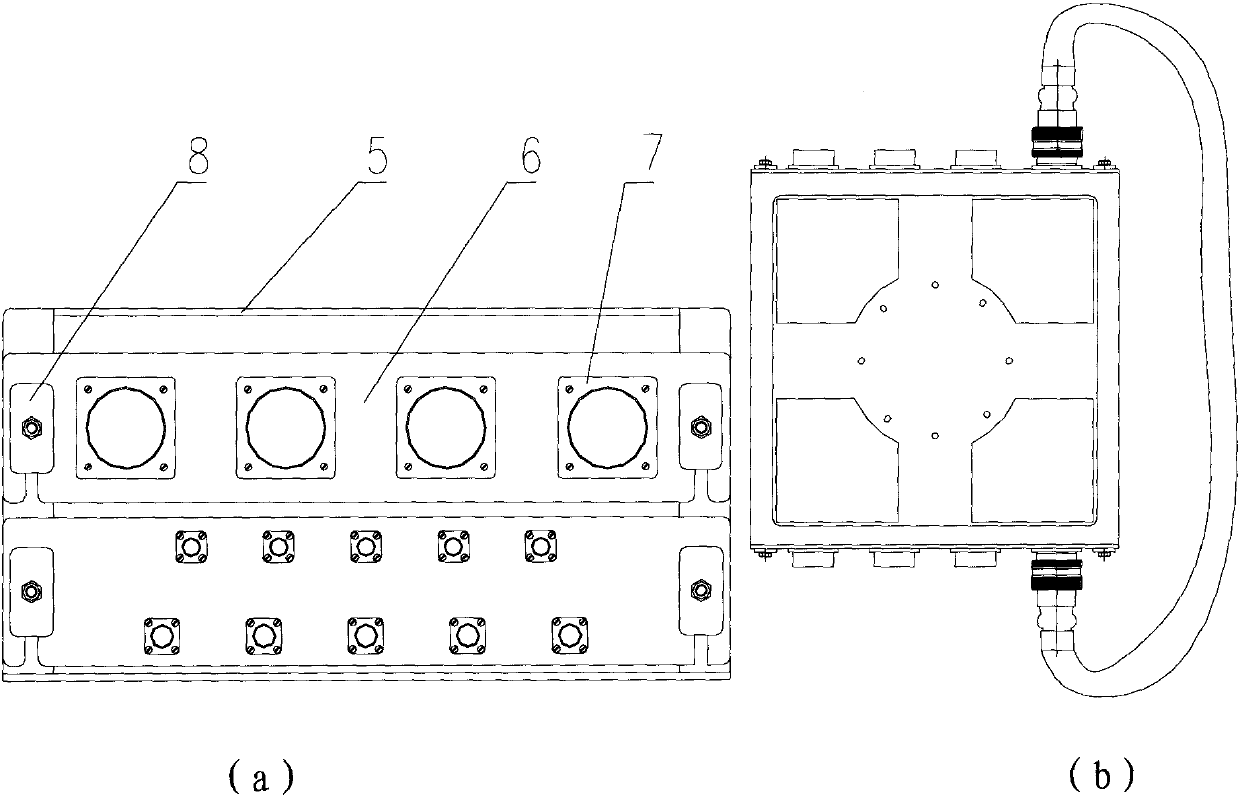

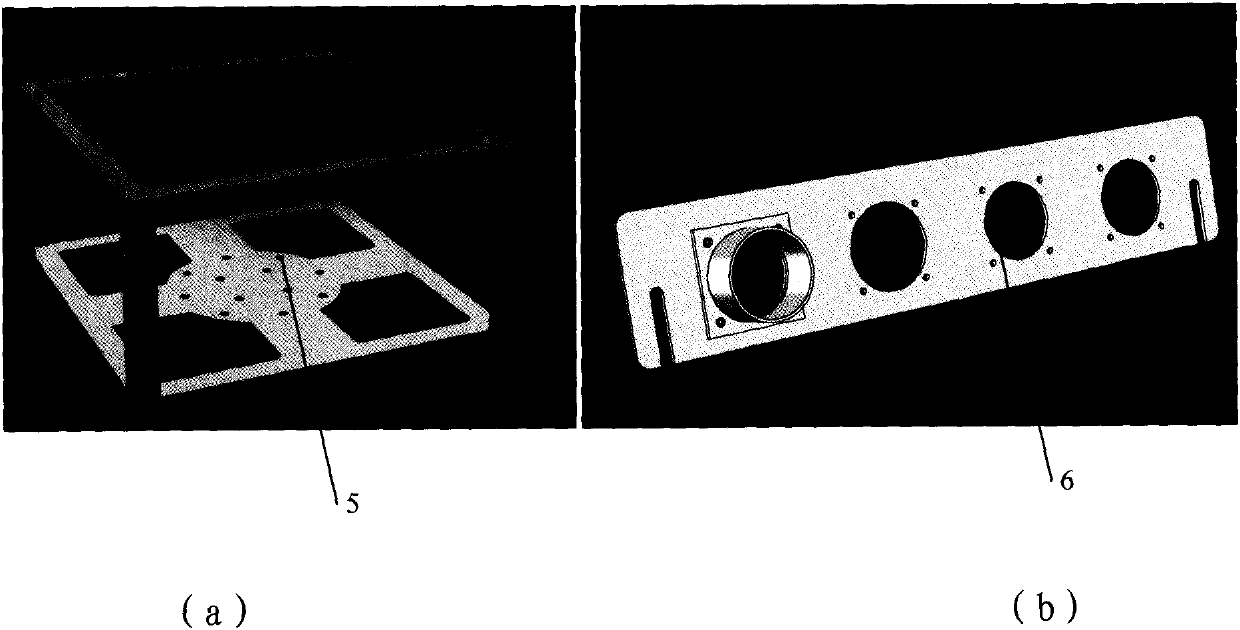

[0014] Such as figure 1 , figure 2 As shown, the cable vibration tooling is composed of a mounting frame 5, a plurality of mounting plates 6, a hollow plug 7, and a pressure plate 8; the mounting frame 5 is a welded structural part: there is a light hole at the bottom, which can be fixed on the vibration test table 4 by screws; Mounting frame 5 side can be used for the connection of mounting frame 5 and mounting plate 6 behind the hole installation screw. Mounting plate 6 plate parts: there are round holes for installing the hollow plug 7, and long holes for connecting with the mounting frame 5. The mounting plate 6 and the mounting frame 5 of the cable vibration tooling adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com