Automatic stamping device for automobile holder

A stamping device and cage technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, increased accident risk, and large demand for personnel, so as to improve production efficiency, production and maintenance The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are given in conjunction with the embodiments.

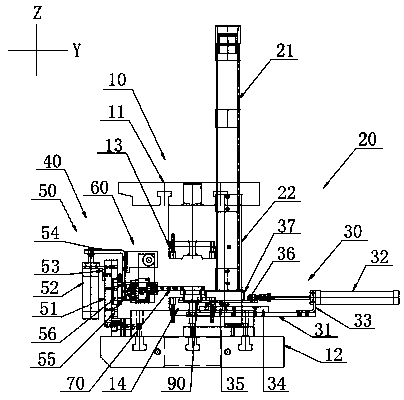

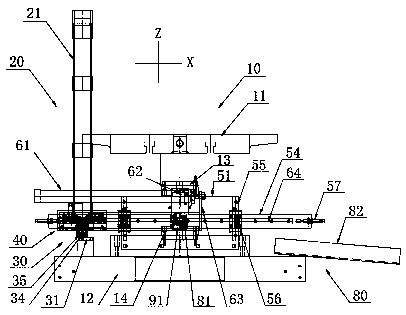

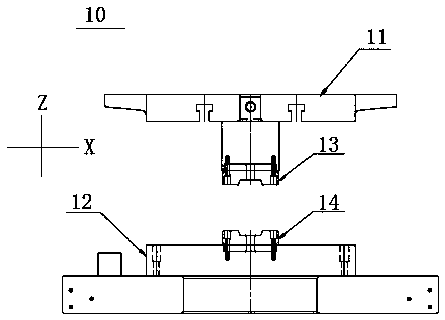

[0034] Please refer to Figure 1 to Figure 9 , figure 1 It is a left side view of an automatic punching device for an automobile cage according to Embodiment 1 of the present invention; figure 2 It is a front view of an automatic punching device for an automobile cage according to Embodiment 1 of the present invention; image 3 It is a front view of a punch in an automatic punching device for an automobile cage according to Embodiment 1 of the present invention; Figure 4 It is the left side view of the feeding mechanism in the automatic stamping device for automobile cage according to Embodiment 1 of the present invention; Figure 5It is a left view of the up and down moving assembly in an automatic stamping device for an automobile cage according to Embodiment 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com