Core material thickness chamfering method of fan blade

A technology for fan blades and core materials, which is used in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of long time-consuming chamfering and low chamfering accuracy of core materials, and achieve the effect of high cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

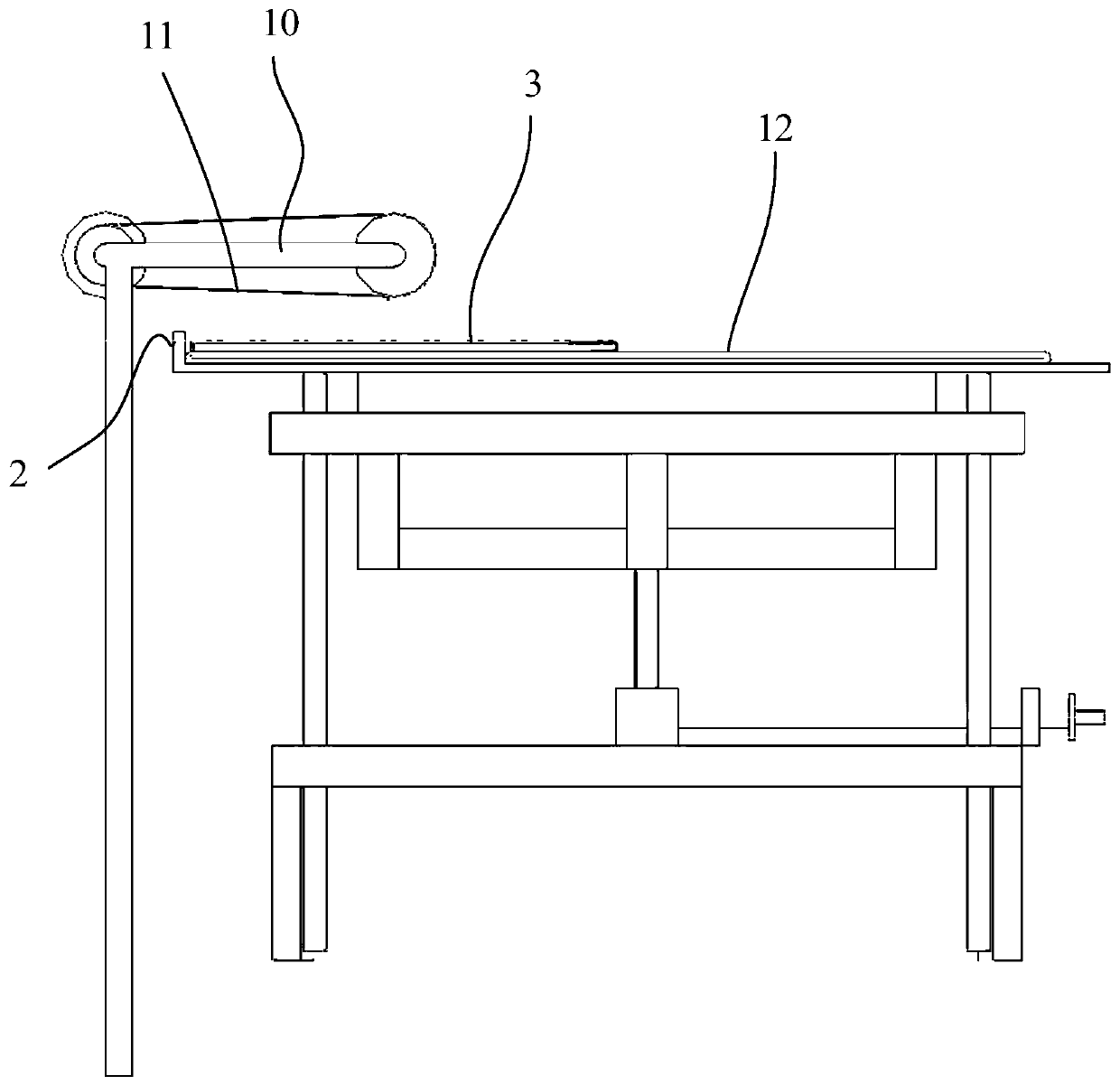

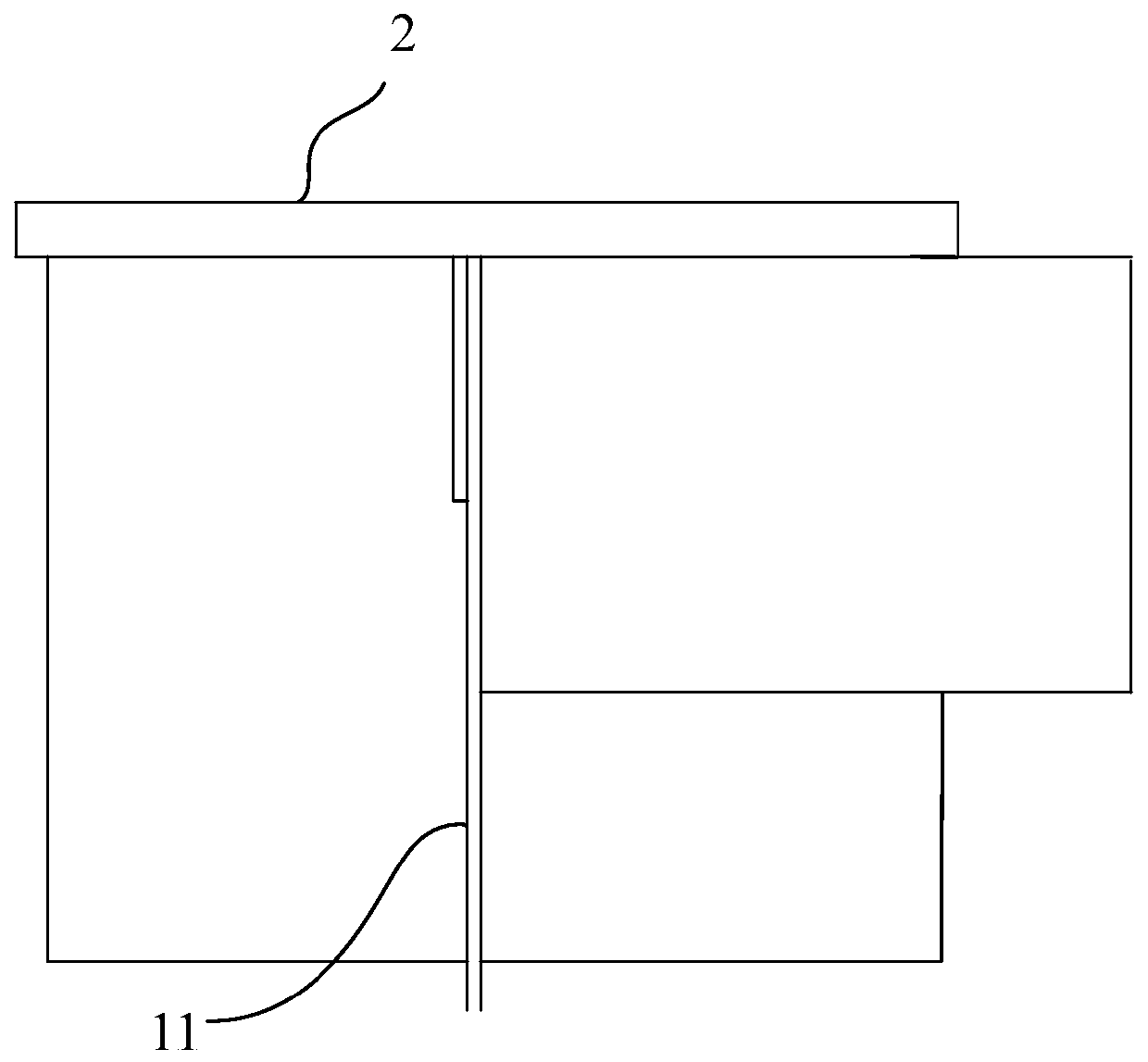

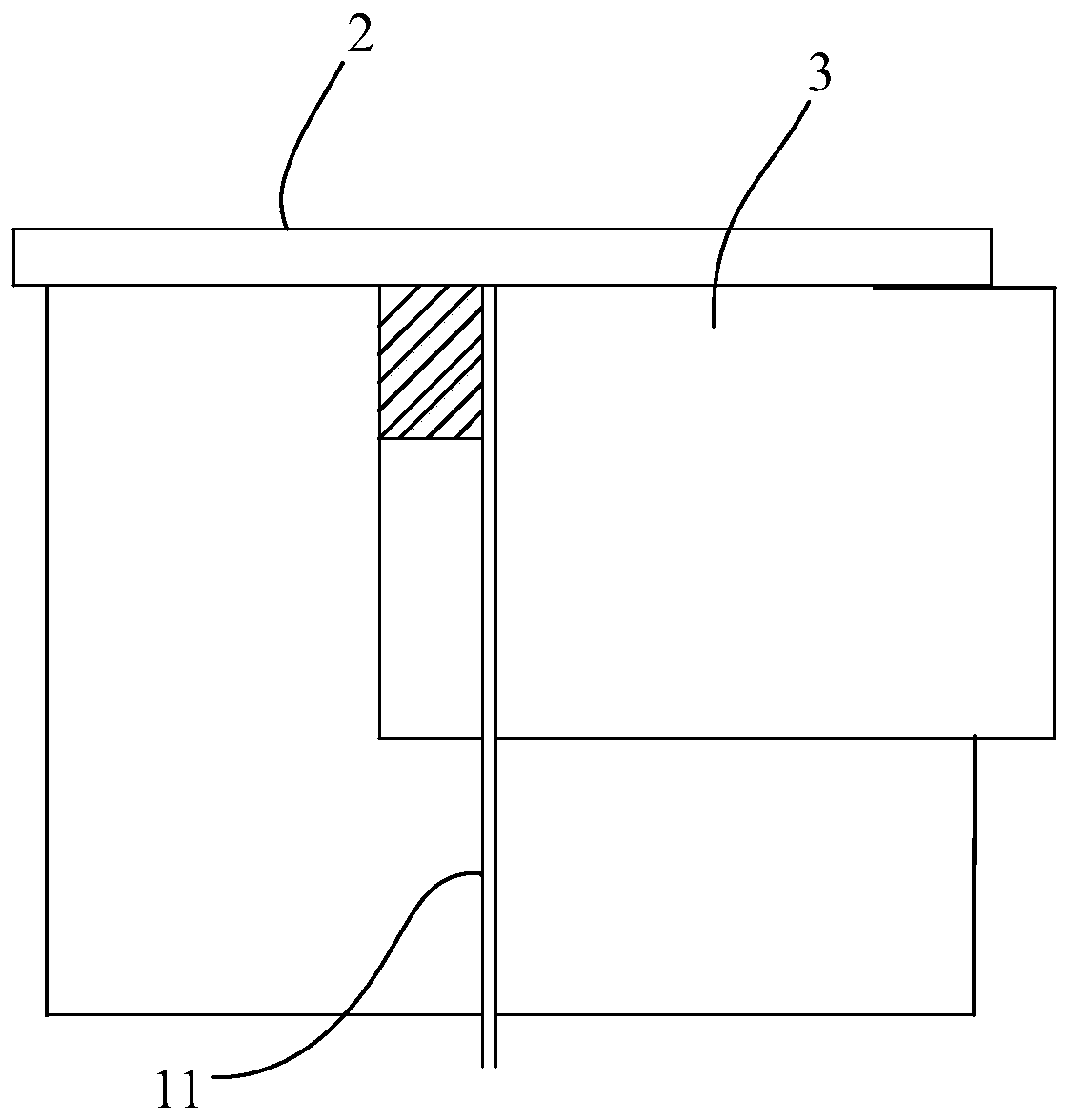

[0029] Such as Figure 1-Figure 4 As shown, this embodiment discloses a method for chamfering the thickness of the core material of the fan blade, wherein, as figure 1 As shown, the method for chamfering the thickness of the core material of the fan blade in this embodiment is realized by cutting equipment and includes the following steps:

[0030] Step S1, setting the height between the cutting head 10 of the cutting device and the working table 12 of the cutting device;

[0031] Step S2, setting the relative angle between the saw blade 11 of the cutting machine head 10 and the working surface 12 of the cutting device; wherein, step S1 and step S2 can be interchanged.

[0032] Step S3, pushing in the core material 3 from a direction perpendicular to the extension of the saw blade 11 of the cutting machine head 10;

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com