High-precision polishing machine capable of controlling polishing precision

A polishing machine, high-precision technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding automatic control devices, etc., can solve the problem that the polishing machine is not easy to open and clean the dust, affect the rotational speed of the polishing machine, the motor and the polishing Machine impact and other issues to achieve the effect of improving polishing efficiency and safety, reducing the impact of vibration, and increasing the reliability of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

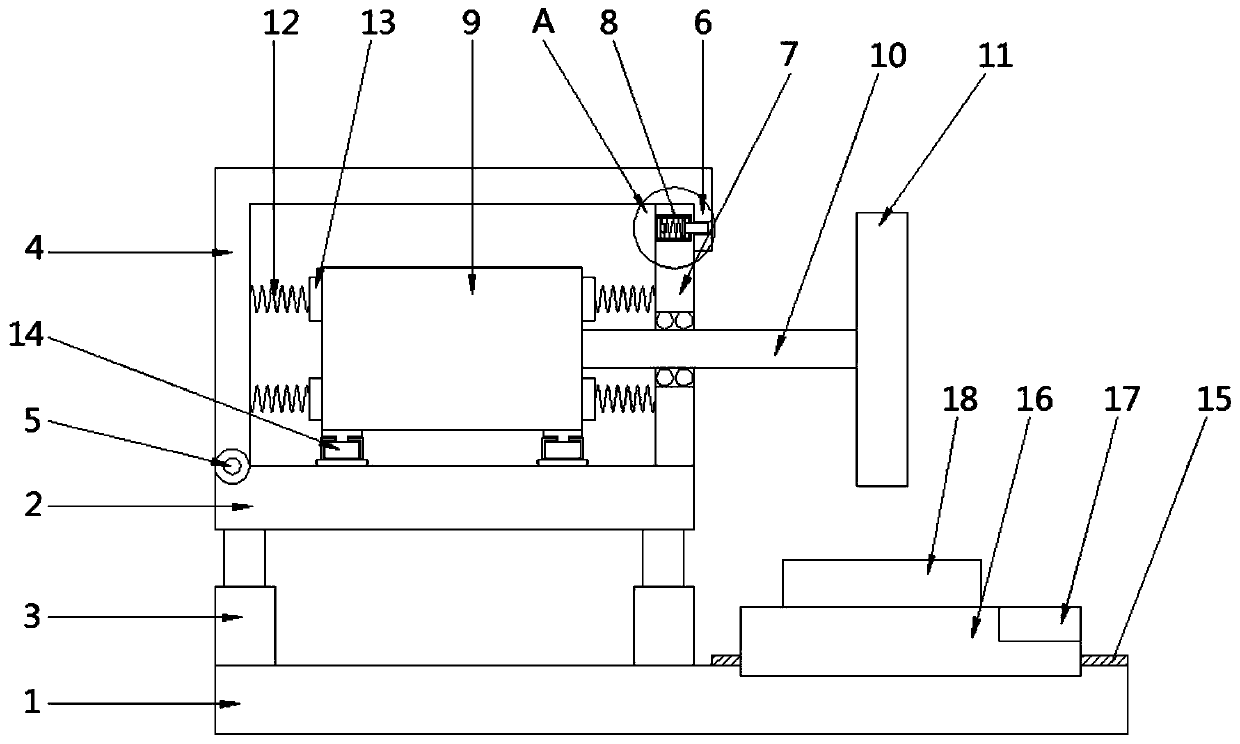

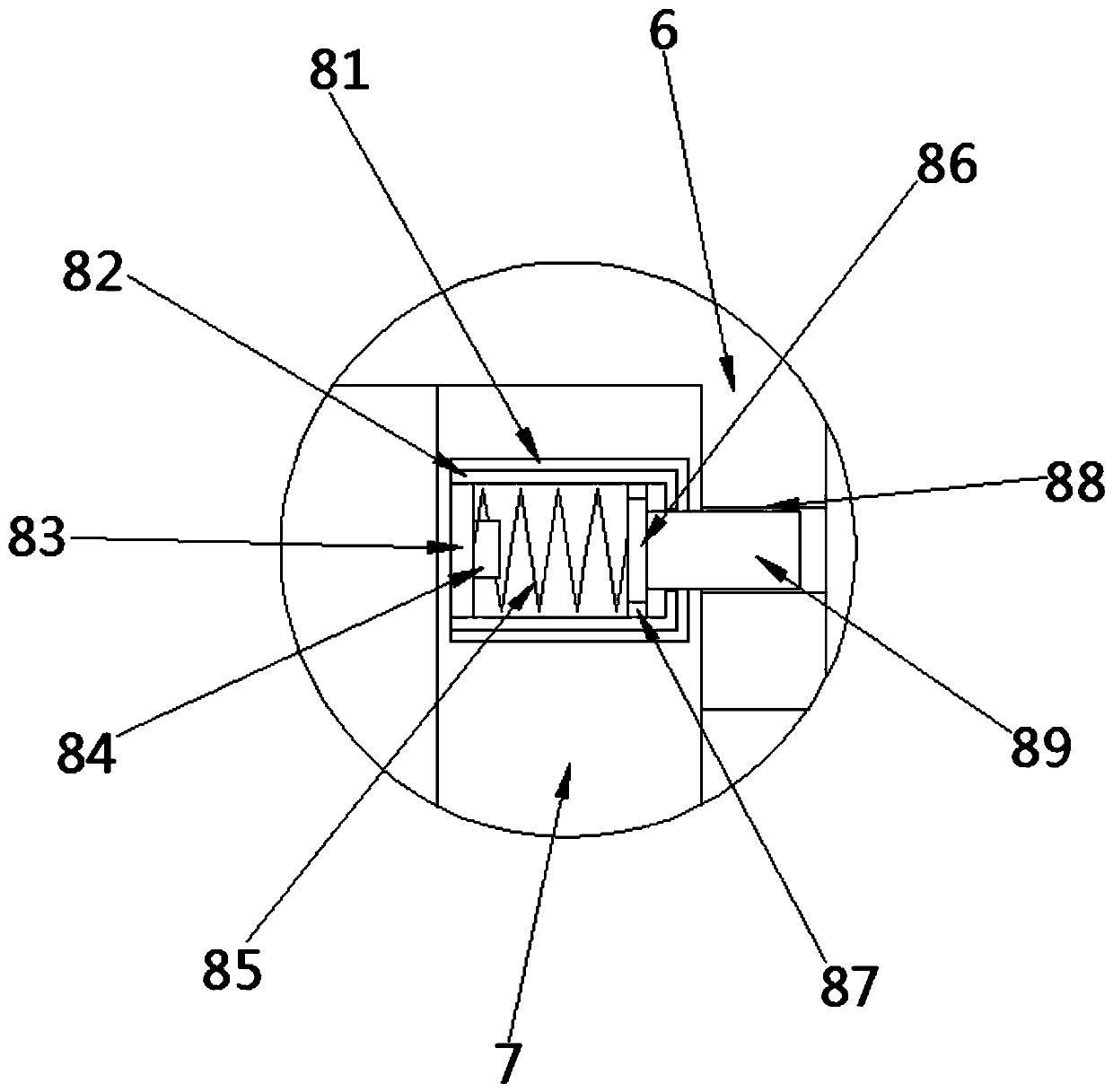

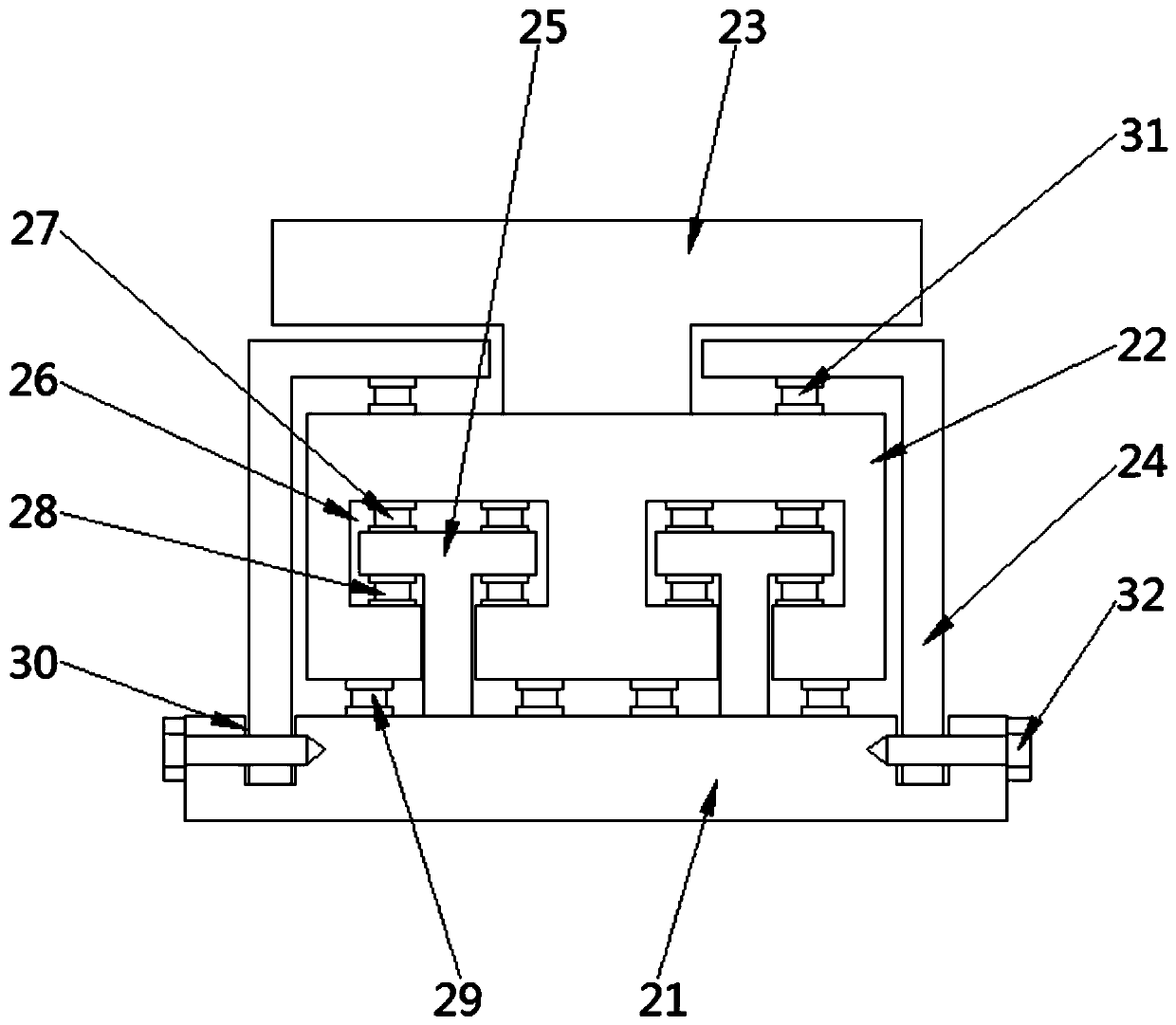

[0040] see figure 1 , a high-precision polishing machine that can control the polishing accuracy, including a base 1 and a motor base 2, hydraulic lifting rods 3 are provided at the four corners of the lower side of the motor base 2, and the hydraulic lifting rods 3 are fixed on the base 1, and the motor base The upper side of 2 is provided with cover plate 4, and the bottom left side of cover plate 4 is connected with the left end of motor base 2 through pin shaft 5 and rotates, and cover plate 4 is an L-shaped plate including vertical plate and horizontal plate, and the right end of horizontal plate Also integrally formed with a clamping plate 6, the upper right end of the motor base 2 is provided with a support plate 7, the clamping plate 6 is clamped with the support plate 7, the upper side of the motor base 2 is provided with a servo motor 9, and the output end of the servo motor 9 is connected to There is an output shaft 10, the right end of the output shaft 10 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com