Charging port cover assembly

A charging port and cover technology, which is applied to charging stations, superstructure sub-assemblies, electric vehicle charging technology, etc., can solve the problems of actuators not unlocking, Z-direction deviation of the cover outer plate, shaking, etc., to avoid The effect of water ineffective, easy to open and close

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

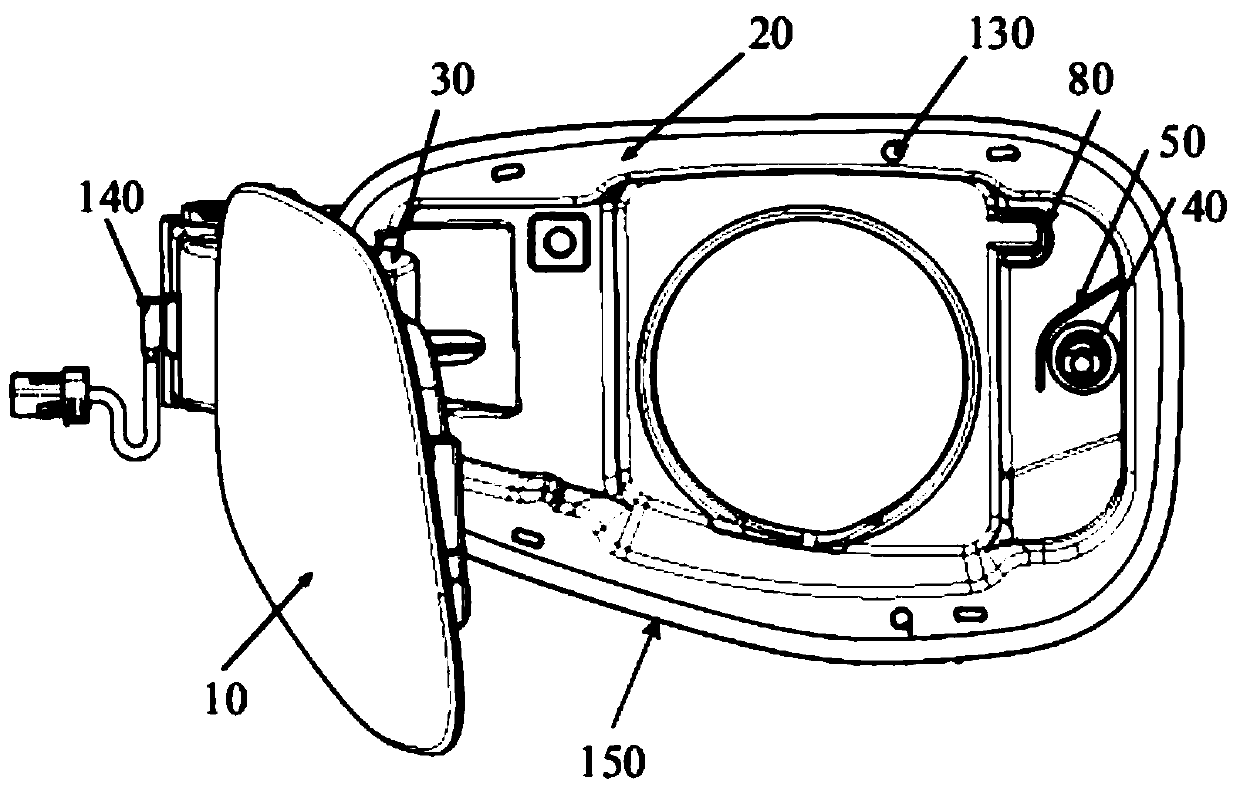

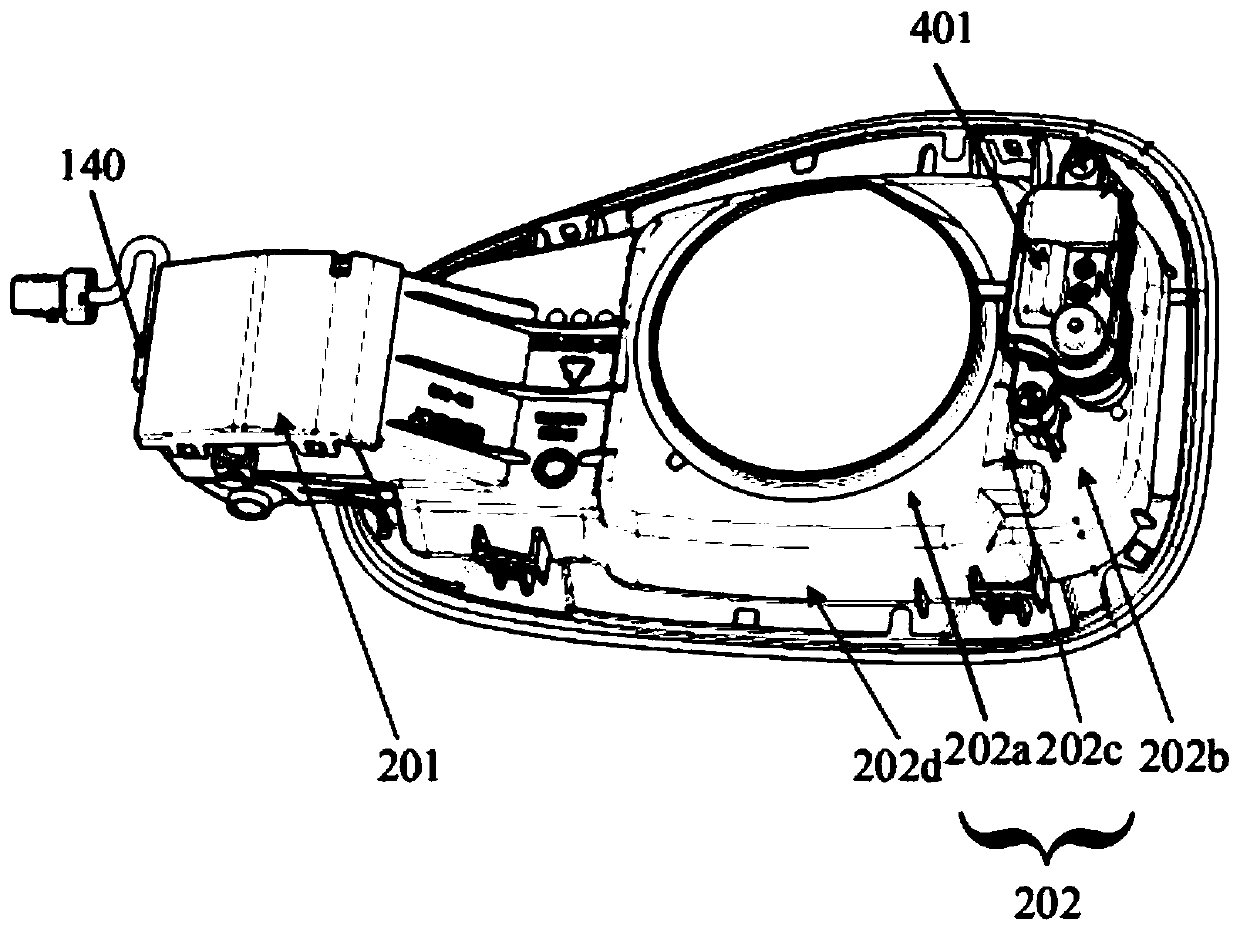

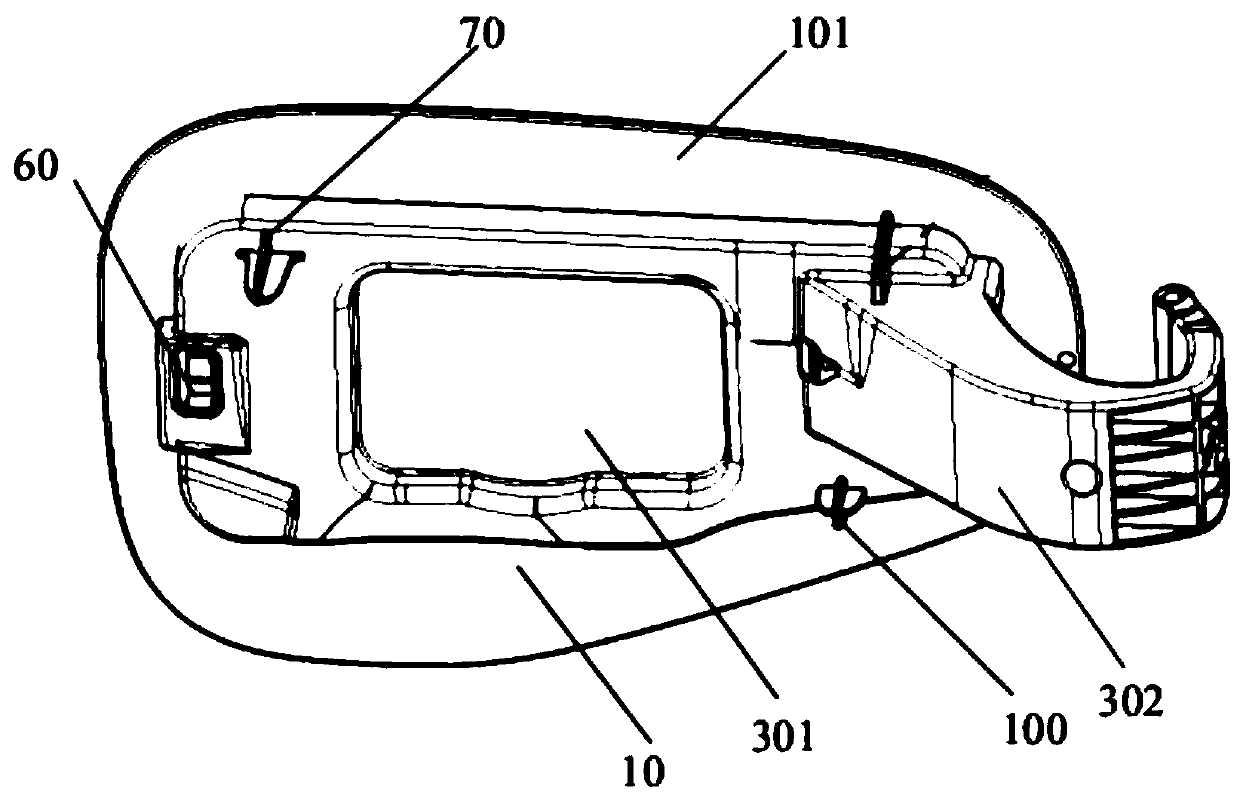

[0031] see Figure 1 to Figure 3 , the charging port cover assembly provided by the present invention includes a cover 10 and a cover base 20, the cover 10 includes a cover 101 and a hinge 30 fixed to the cover 101, one end of the hinge 30 is fixed to the cover 101, the hinge 30 The other end is pivotally connected to the inside of the cover base 20 , and the cover plate 101 is covered on the cover base 20 .

[0032] Specifically, the cover base 20 includes a front box 201 and a rear box 202 located at the rear end of the front box 201. The front end of the front box 201 is provided with a micro switch 140, and the micro switch 140 is a waterproof micro switch. At the same time, waterproof connectors are used for the micro switch equipment end and the wiring harness end. The hinge 30 includes a fixed plate 301 and a rotating arm 302 extending from the fixed plate 301. The fixed plate 301 is connected to the cover plate 101. The free end of the rotating arm 302 is pivotally co...

no. 2 example

[0039] The structure and positional relationship of the elements in this embodiment are basically the same as those of the first embodiment, the difference is that:

[0040] see Figure 6 and Figure 7 , the second bottom plate 202b of the cover base 20 is provided with two plate-shaped rain eyebrows 50 on both sides of the actuator push rod 402, and the side walls of the two opposite sides of the limiter 60 are protrudingly provided with rain eyebrows 50 Corresponding to the second guide post 90, the second guide post 90 replaces the first guide post 70 in the first embodiment. When the cover 10 is closed, the second guide post 90 and the stopper 60 are fixed on the two rain eyebrows 50 The positioning between them is more concise and beautiful than the structure of the first embodiment.

[0041] see Figure 8 Further, the first limiting rib 100 is replaced by the second limiting rib 110, and the second limiting rib 110 is protrudingly arranged on both sides of the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com