Multi-stage pump starting method, system and equipment

A multi-stage pump and preset threshold technology, applied in mining equipment, mechanical equipment, pumps, etc., can solve problems such as unusable, misjudgment, failure to fill water or fail to start the pump, etc., to avoid failure to fill water and avoid errors , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

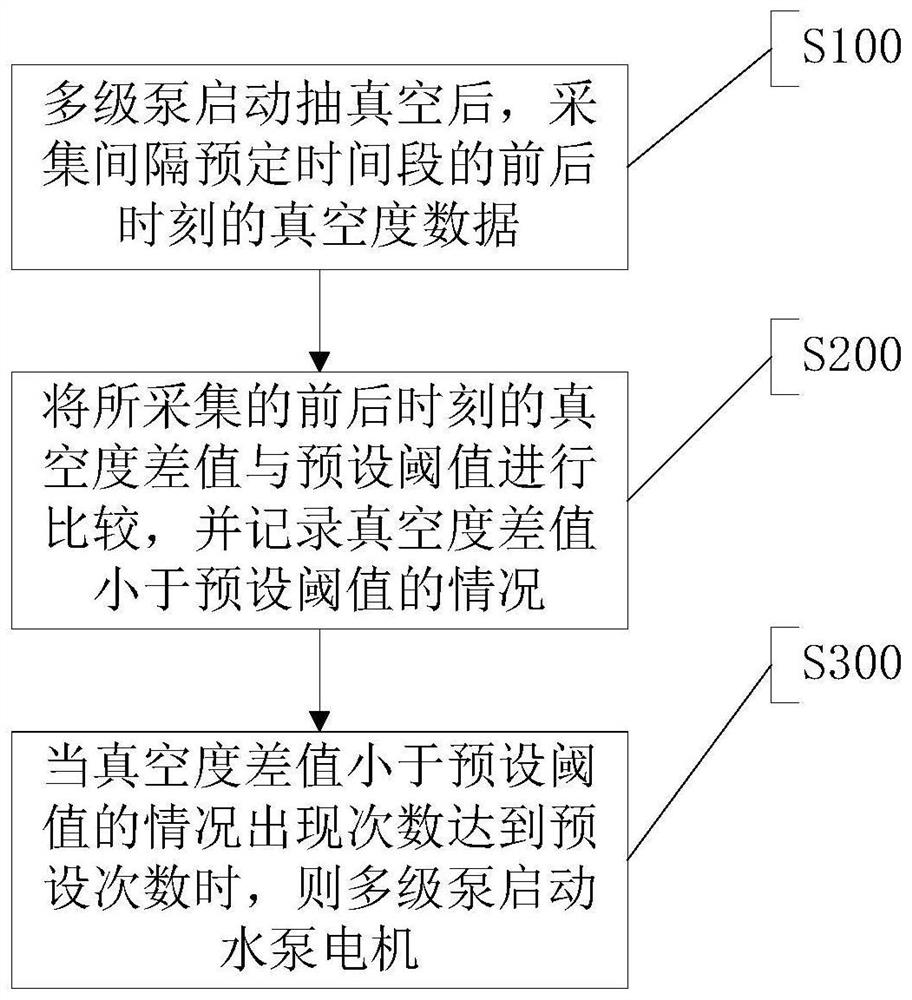

[0031] Such as figure 1 Shown, a kind of multi-stage pump starting method comprises the following steps:

[0032] S100. After the multi-stage pump starts vacuuming, collect vacuum degree data before and after a predetermined time interval;

[0033] S200. Comparing the collected vacuum degree difference with the preset threshold value, and recording the vacuum degree difference value being smaller than the preset threshold value;

[0034] S300. When the number of times that the vacuum difference is smaller than the preset threshold reaches the preset number of times, the multi-stage pump starts the water pump motor.

[0035] Through research and observation, it is found that the change law of the vacuum degree of the pump body during vacuum pumping is: the initial stage of the vacuum degree continues to rise, that is, it is constantly changing, and when the conditions for starting the pump are finally met, the vacuum degree does not change or changes within a small range. Yes...

Embodiment 2

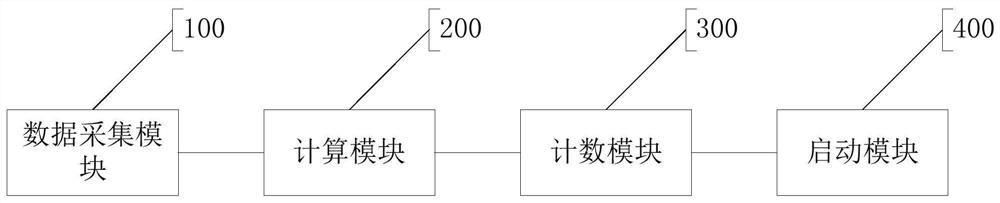

[0051] Such as figure 2 As shown, a multi-stage pump starting system includes:

[0052]The data collection module 100 is used to collect the vacuum degree data before and after the predetermined time period after the multi-stage pump starts vacuuming;

[0053] Calculation module 200, used to compare the difference in vacuum degrees collected by the data collection module with the preset threshold;

[0054] The counting module 300 is used to record the situation that the vacuum degree difference calculated by the calculation module is less than a preset threshold;

[0055] The starting module 400 is configured to start the water pump motor when the counting module records that the vacuum degree difference value is less than the preset threshold value and the number of occurrences reaches the preset number of times.

[0056] Through research and observation, it is found that the change law of the vacuum degree of the pump body during vacuum pumping is: the initial stage of th...

Embodiment 3

[0072] A multi-stage pump starting device comprising at least one processor;

[0073] And a memory connected in communication with at least one processor; wherein, the memory stores an instruction program that can be executed by at least one processor, and the instruction program is executed by at least one processor, so that at least one processor can perform as listed in Embodiment 1 A multi-stage pump starting method.

[0074] Wherein, the command program includes a multi-stage pump starting system as listed in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com