Fragmentation device

A technology of substrate and block, which is applied in pile separation, object separation, transportation and packaging, etc., can solve the problem that the sensor is not suitable for underwater work, and achieve the effect of avoiding water failure, ensuring work efficiency, and saving use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

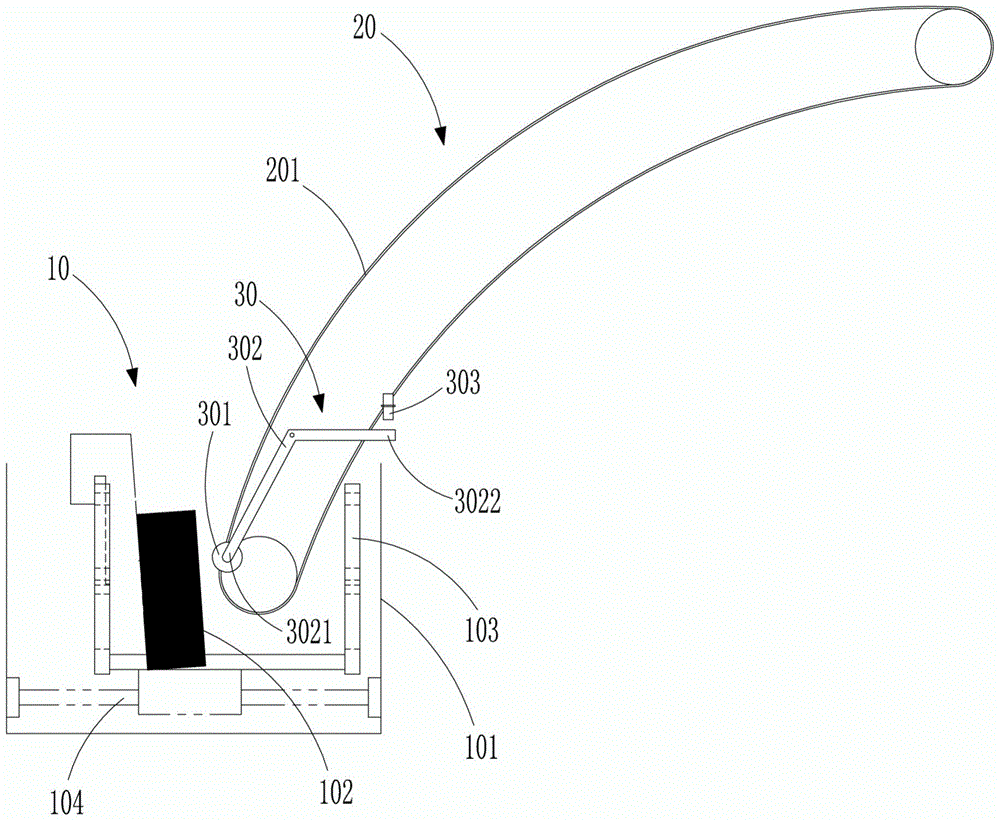

[0017] as attached figure 1 As shown, a slicer includes a feeding unit 10, a suction unit 20 and an induction unit 30. The feeding unit 10 is arranged in a water tank 101, and the feeding unit 10 is placed with multiple The substrate stack 102 of substrates, each substrate is arranged along a substantially vertical plane, and the substrates are completely positioned under the water surface in the water tank 101; Through the vacuum suction hole, the conveyer belt 201 is partially arranged in the water tank 101 and this part extends to the feeding unit 10. Generally, the bottom-up conveying method is selected, so the lower end of the suction unit 20 is arranged in the water tank 101, that is, The substrates are transported from the relative lower end of the conveyor belt 201 to the relative upper end. When the substrate stack 102 is fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com