Automatic packaging method and system based on machine vision

A technology of automatic packaging and machine vision, applied in the field of packaging, can solve the problems of large amount of information, low storage efficiency of packaging data, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

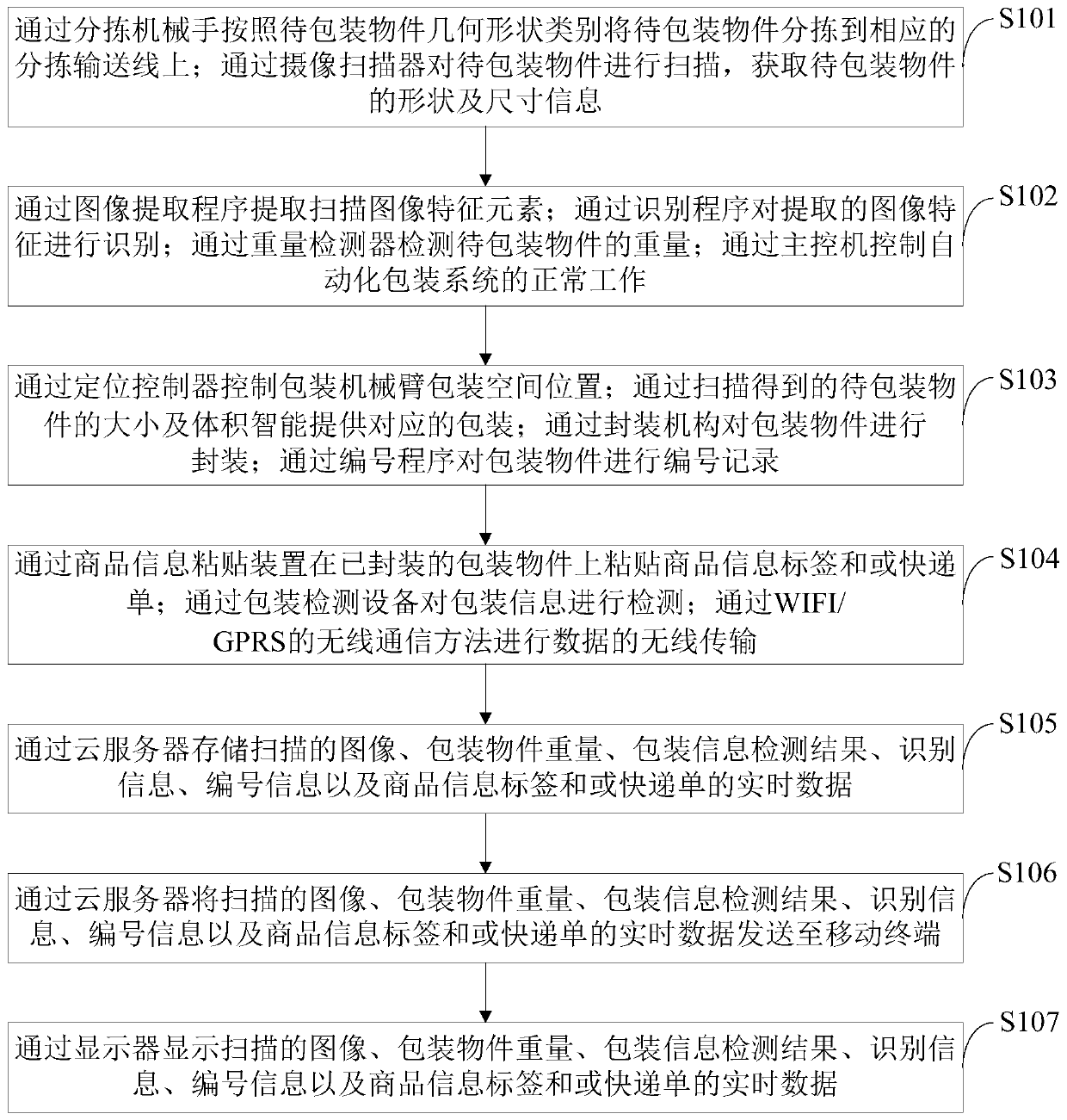

[0109] The automatic packaging method based on machine vision provided by the embodiment of the present invention is as follows figure 1 As shown, as a preferred embodiment, the method for controlling the packaging space position of a packaging robot arm through a positioning controller using a positioning program provided by an embodiment of the present invention includes:

[0110] (1) Determine the reference position of the moving object to be packaged, obtain the position data of the reference position, and use the position data of the reference position as the default correction road sign.

[0111] (2) Obtain the path and orientation of the moving object to be packaged when moving in space.

[0112] (3) Calculate the movement trajectory of the object to be packaged according to the acquired path and orientation of the moving object to be packaged, and obtain the position data of the object to be packaged according to the movement trajectory of the object to be packaged.

[0113] (4...

Embodiment 2

[0122] The automatic packaging method based on machine vision provided by the embodiment of the present invention is as follows figure 1 As shown, as a preferred embodiment, the method for detecting packaging information through a packaging detection device provided by the embodiment of the present invention is as follows:

[0123] (1) Configure the working parameters of the packaging inspection equipment, and obtain the outer barcode image and the inner barcode image of the package to be inspected through the packaging inspection device. Through the image enhancement program to enhance the collected images.

[0124] (2) Identify the outer barcode image, acquire outer packaging information, identify the inner barcode image, and acquire inner packaging information, wherein the outer packaging information includes user identification information.

[0125] (3) Query the preset outer packaging information corresponding to the user identification information from the preset database.

[01...

Embodiment 3

[0134] The automatic packaging method based on machine vision provided by the embodiment of the present invention is as follows figure 1 As shown, as a preferred embodiment, the method for storing data through a cloud server provided by the embodiment of the present invention is:

[0135] 1) The inspection data is transmitted to the cloud server through the packaging inspection equipment through the network, and the packaging inspection result database is created through the cloud server.

[0136] 2) Establish a value table for storing the value of the package test result in the package test result database. Store the package test result value in the value table.

[0137] 3) Establish an attribute table and a status table for storing the attribute information and status information of the package testing result in the package testing result database. The attribute information and status information of the packaging inspection results are respectively stored in the attribute table an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com