Overspeed brake device of rubber belt conveyor

A belt conveyor and brake device technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of belt conveyor overspeed, achieve the effect of simple control, stable structure, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

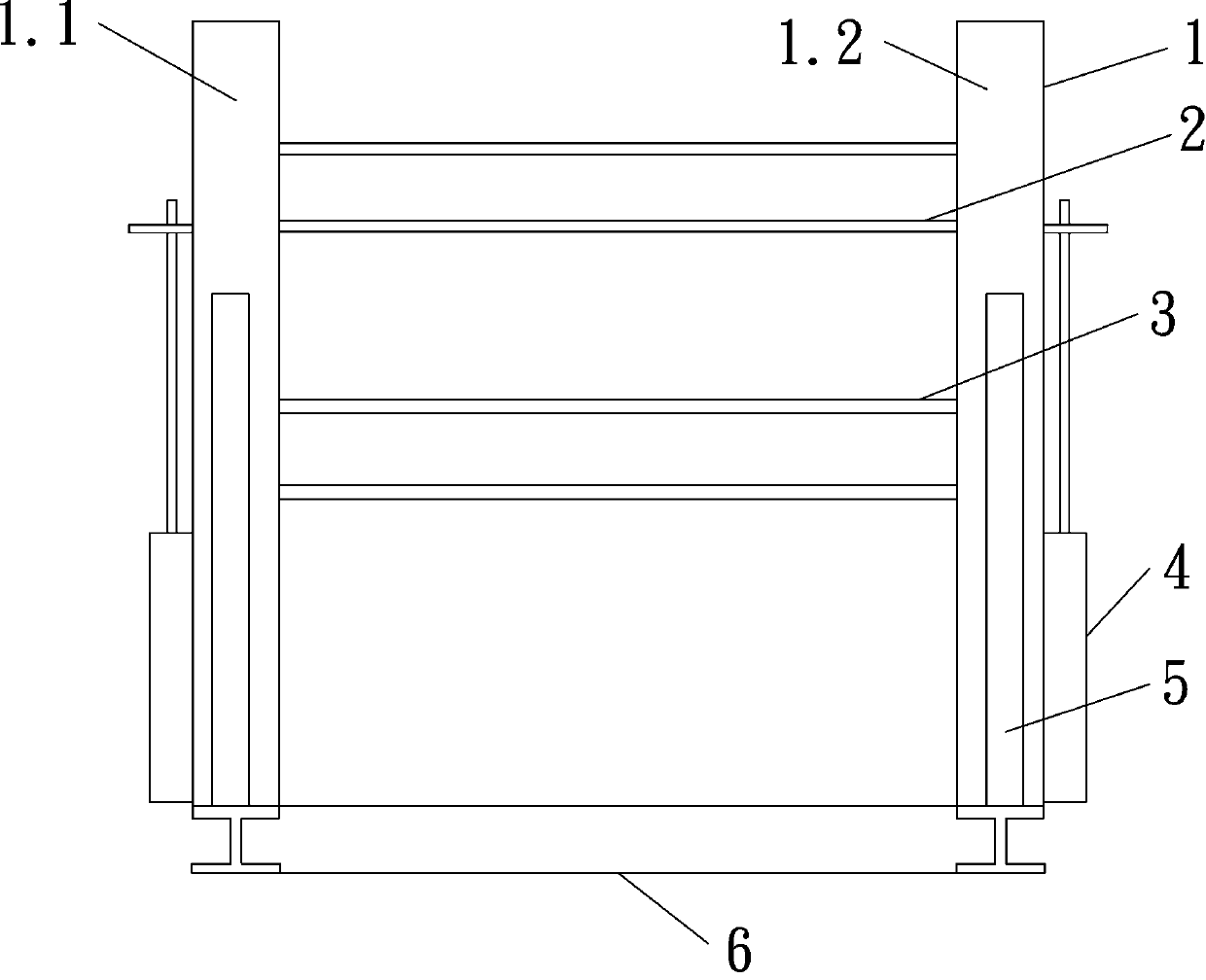

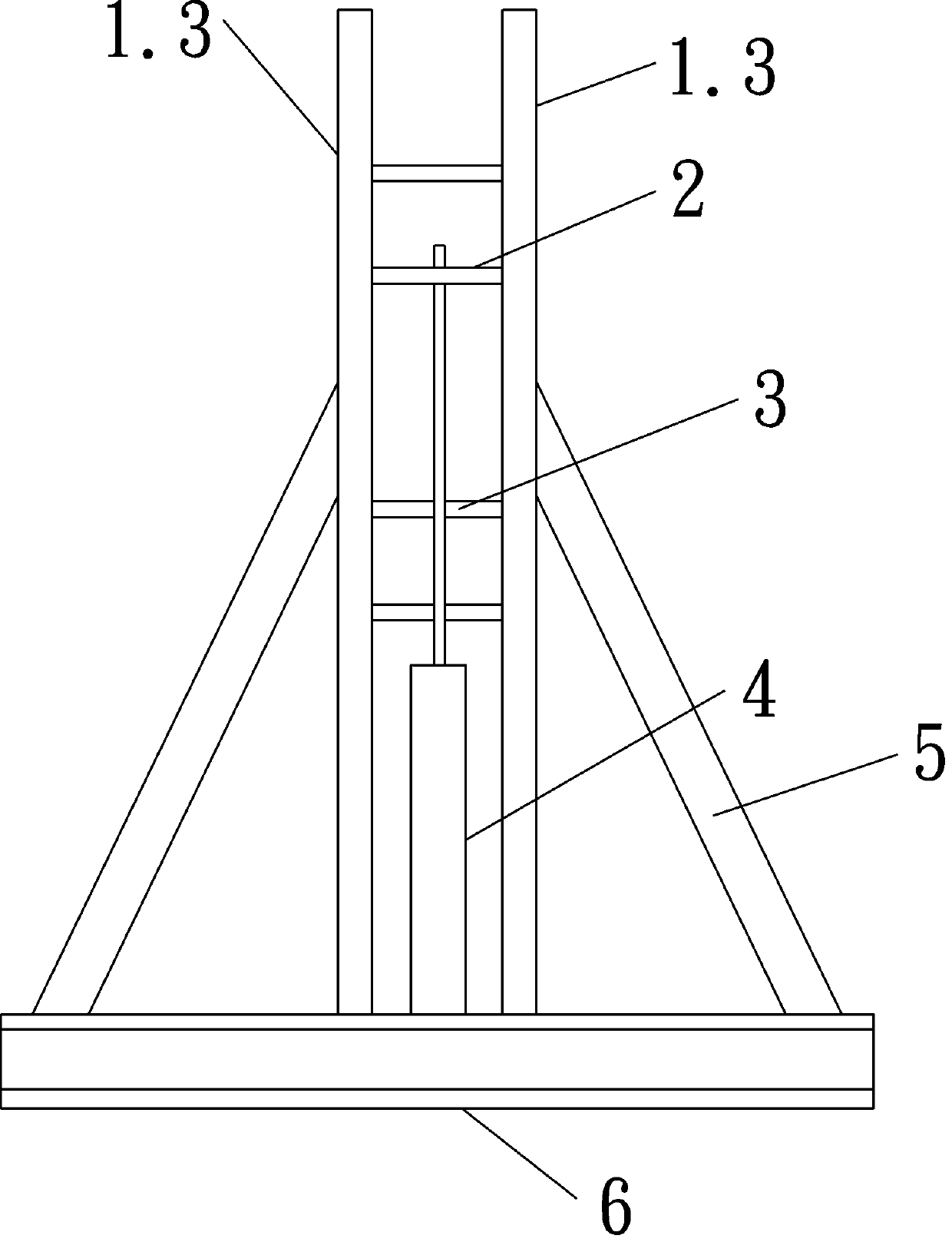

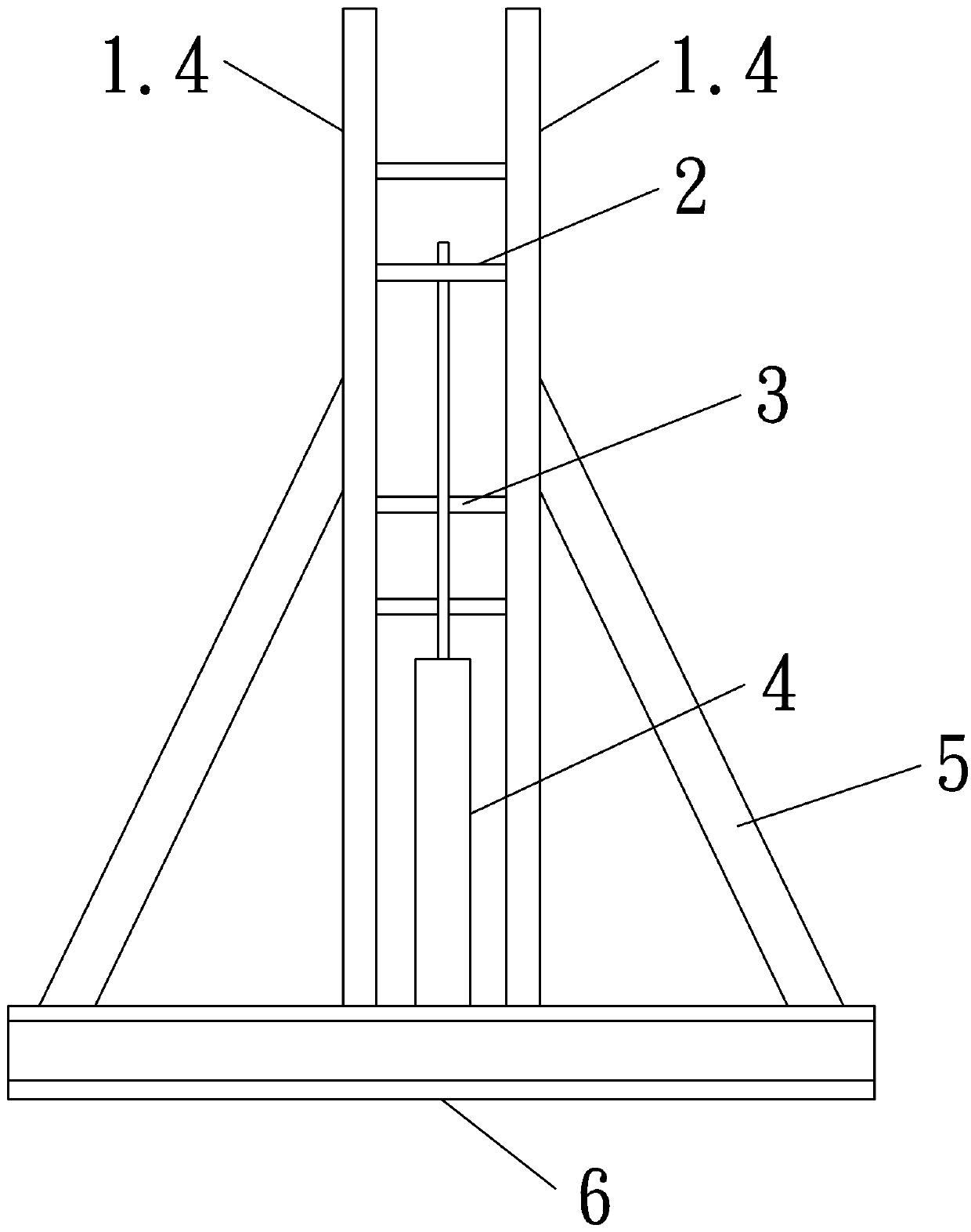

[0041] Such as Figure 1-3 As shown, the belt conveyor overspeed braking device includes a frame body 1, an upper movable brake device 2 is installed on the upper part of the frame body 1, a lower fixed brake device 3 is installed on the lower part of the frame body 1, and a movable brake device 3 is installed on the upper part of the frame body 1. The device 2 and the lower fixed brake device 3 are arranged opposite to each other. When the upper movable brake device 2 and the lower fixed brake device 3 are close to each other, they can squeeze the lower adhesive tape, and then apply a certain pre-pressure. The pneumatic device 4 is also included, and the pneumatic device 4 can Drive the upper movable brake device 2 to approach or move away from the lower fixed brake device 3. When the belt conveyor is overspeed, pull the control valve to realize the contraction of the pneumatic device 4, and the contraction of the cylinder of the pneumatic device 4 drives the upper movable bra...

Embodiment 2

[0043] Embodiment two, such as Figure 4-8 As shown, the difference from Embodiment 1 is that the pneumatic device 4 is replaced by a clamping cylinder 7.5, which also includes a fixed guide 7, and the upper movable brake device 2 is made of I-shaped steel, which includes ribs Plate one 2.2 and the first upper wing plate 2.1 and the second lower wing plate 2.3 vertically connected to the rib plate one 2.2, the first upper wing plate 2.1 and the second lower wing plate 2.3 are parallel to the lower adhesive tape, and They are respectively arranged at both ends of the first rib plate 2.2, and the second lower wing plate 2.3 is located above the lower adhesive tape. The fixed guide 7 includes an outer casing 7.1 with a rectangular cross-section and openings at both ends. The lower part of the outer casing 7.1 Along its length, the surface is provided with a long hole 7.3 for the rib plate 1 2.2 to pass through, and a vertical guide side plate 7.2 is respectively arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com