Suspension driving module with lifting mechanism and automatic guide transmission vehicle

A driving module and driving mechanism technology, applied in the direction of lifting devices, etc., can solve the problems of damage to the motor, reduce the service life of the motor, and high cost, and achieve the effects of simple and convenient use, wide application range, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

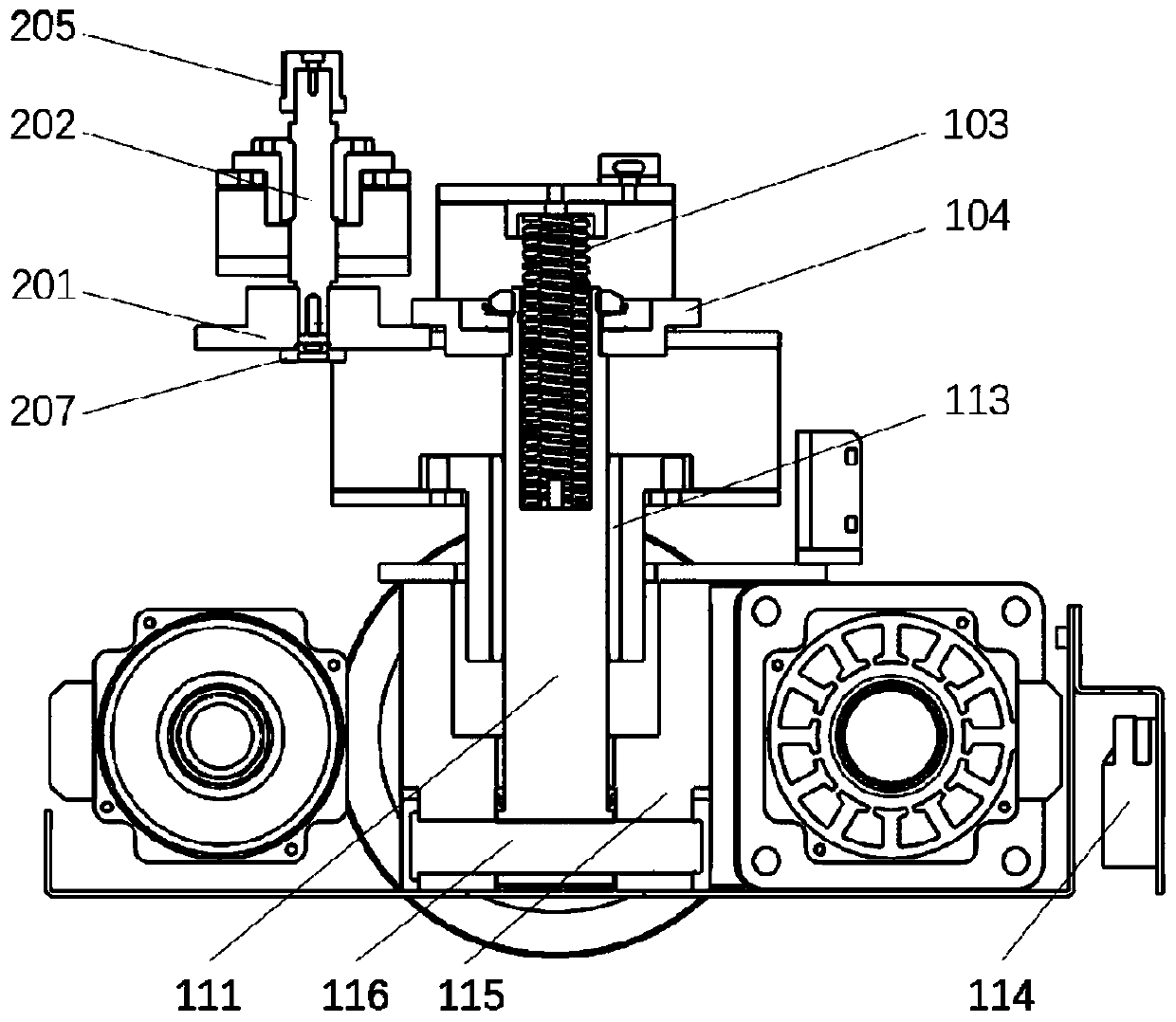

[0039] Such as figure 1 As shown, a suspension drive module with a lifting mechanism in this embodiment includes:

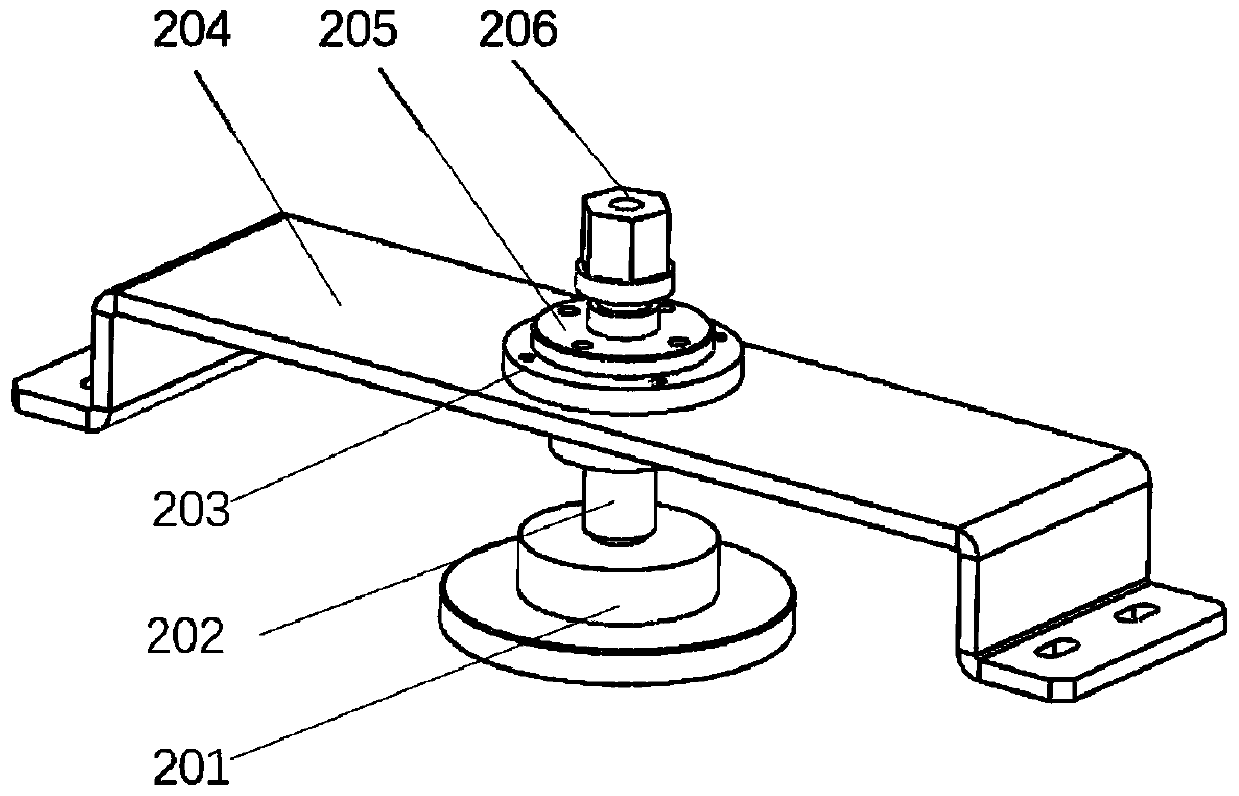

[0040] A lifting mechanism, which includes a screw mandrel 202, the bottom of which is equipped with a first flange 201;

[0041] The suspension drive mechanism includes a spring 103, the spring 103 is covered with a second flange 104, and the second flange 104 is arranged above the first flange 201 and contacts;

[0042] When the screw mandrel moves upward, the first flange 201 moves upward along with the screw mandrel, and at the same time the first flange 201 drives the second flange 104 to move upward, so that the suspension driving mechanism rises and the driving wheel 110 leaves the ground; When the screw mandrel moves downward, the first flange 201 moves downward along with the screw mandrel, and the second flange 104 moves downward under the action of its own gravity and spring force, so that the suspension driving mechanism descends.

[0043] Such as ...

Embodiment approach

[0049] As an implementation manner, the screw nut 205 is installed on the screw nut fixing base 203 , and the screw nut fixing base 203 is installed on the lifting mechanism mounting part 204 .

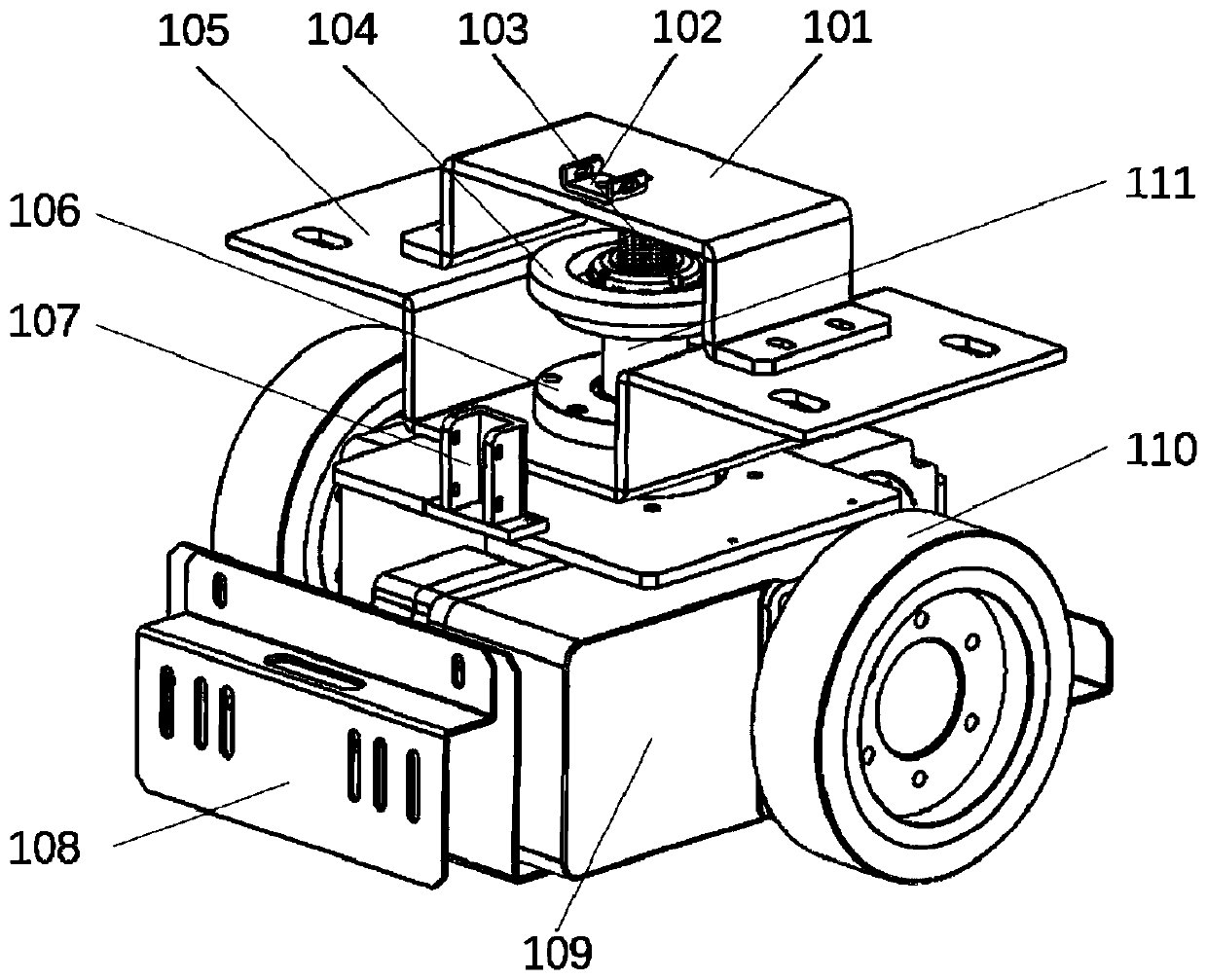

[0050] As an embodiment, the suspension drive mechanism also includes a guide rod 111, the upper end of the guide rod 111 is provided with an opening, and the spring 103 is arranged in the opening; the lower end of the guide rod 111 is connected to the motor reducer 109; The outer 111 of the guide rod is also sleeved with an oil-free bush 113, and the guide rod reciprocates up and down along the oil-free bush under the driving action of the motor reducer.

[0051] Specifically, in the suspension driving mechanism, the motor reducer 109 is installed on the motor reducer fixing part 115, and the lower end of the guide rod 111 is connected with the motor reducer fixing part 115 through the rotating positioning pin 116, and the two can rotate relatively while guiding The rod 111 can recip...

Embodiment 2

[0059] This embodiment provides an automatic guided transport vehicle, which includes the suspension driving module with a lifting mechanism as described in Embodiment 1.

[0060] The automatic guided transport vehicle in this embodiment includes a suspension drive module with a lifting mechanism, which can facilitate manual movement of the automatic guided transport vehicle and protect the motor at the same time.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap