Preparation method of water-soluble phenolic resin

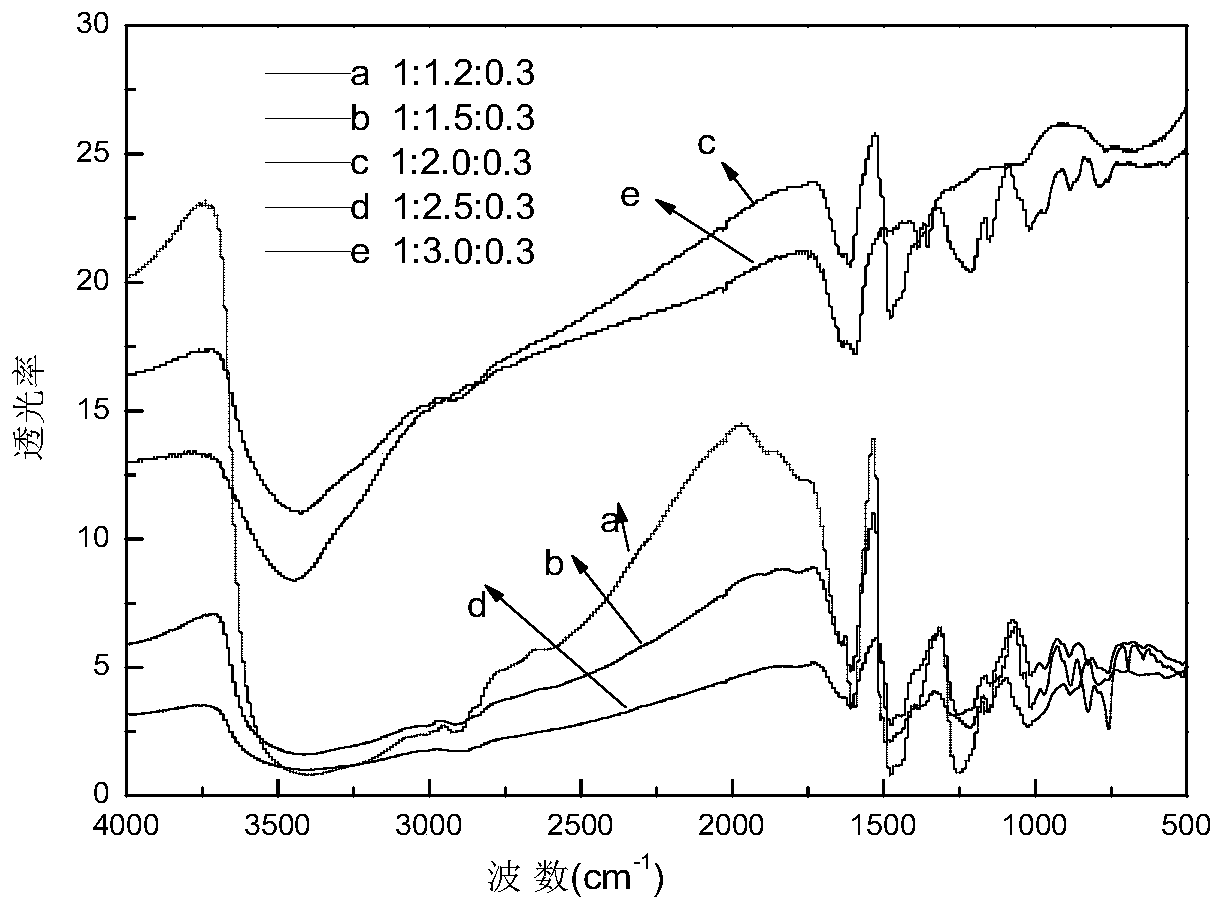

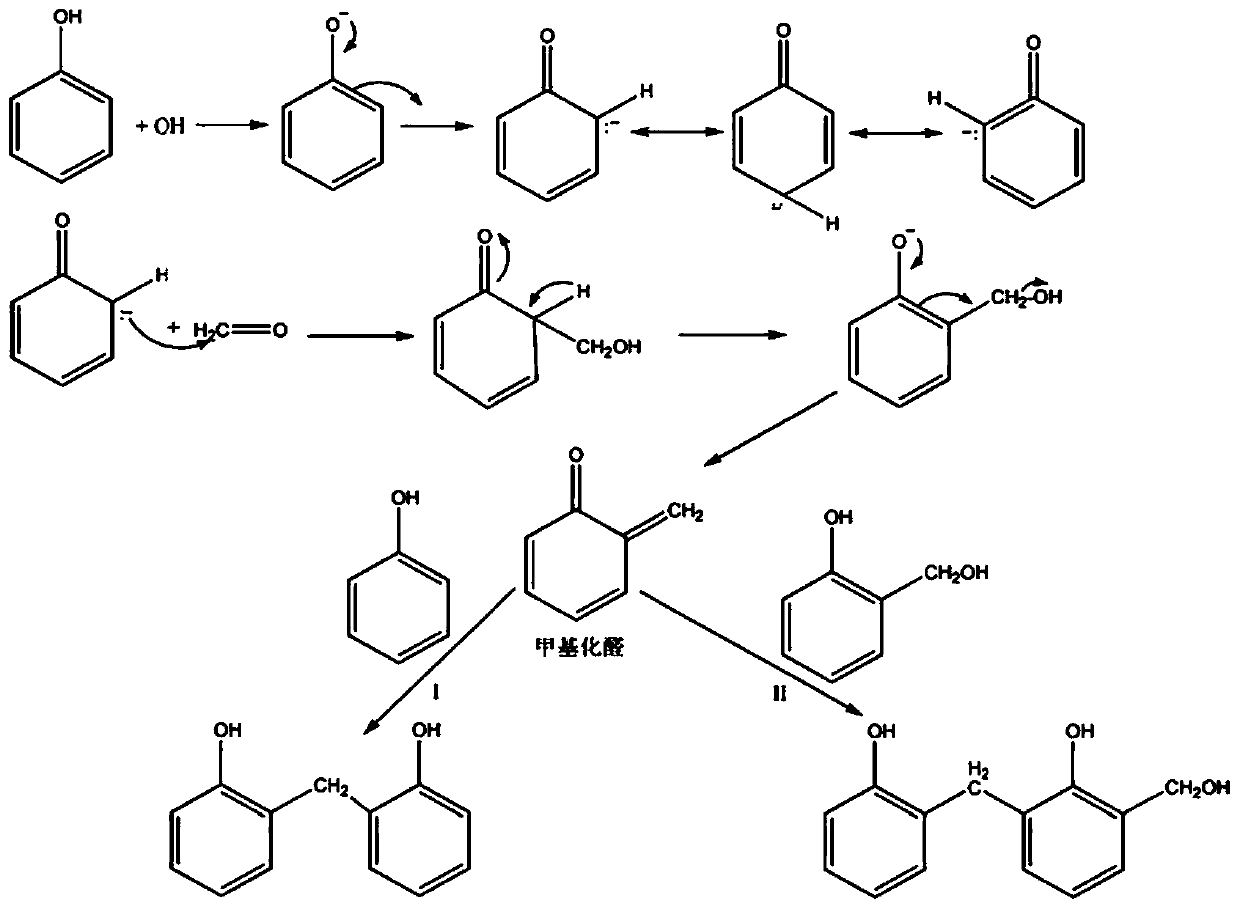

A technology of water-soluble phenolic resin and formaldehyde, which is applied in the field of thermosetting phenolic resin, and can solve problems such as difficult control of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

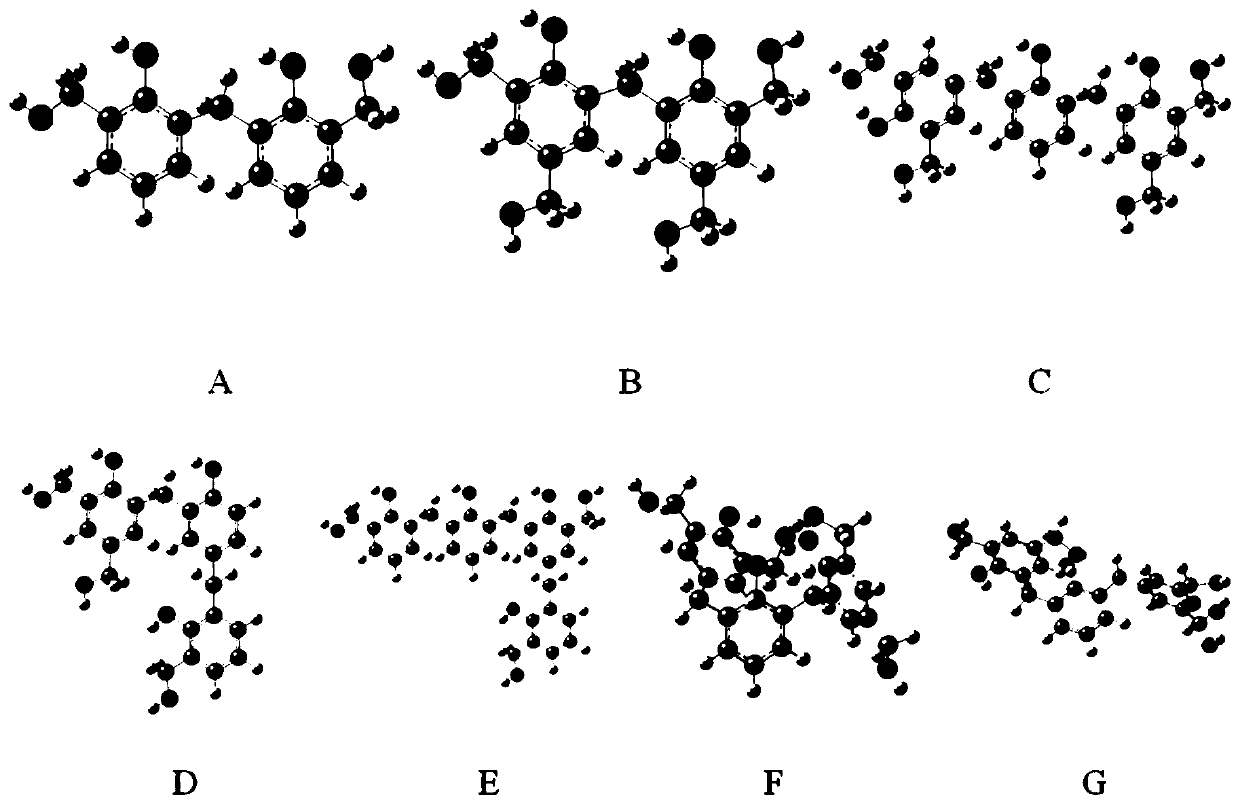

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of water-soluble phenolic resin, comprising the following steps:

[0038] (1) Heating the phenol, the temperature is gradually raised and part of the catalyst is added simultaneously until the temperature rises to the first reaction temperature and the catalyst is added;

[0039] (2) heat preservation reaction at the first reaction temperature, then dropwise add part of formaldehyde and heat up to the second reaction temperature heat preservation reaction, then add the catalyst of the remaining part, continue to heat up to the third reaction temperature;

[0040] (3) heat insulation reaction at the third reaction temperature, then add the remaining part of formaldehyde and heat up to the fourth reaction temperature and keep the temperature, terminate the reaction, wait to be cooled below the fifth reaction temperature, carry out dehydration under reduced pressure under stirring to obtain the described Water-soluble phenolic resin;

[0041] Describe...

Embodiment 1

[0069] In this embodiment, a synthesis process for preparing water-soluble phenolic resin is determined by adjusting the addition method and reaction temperature of the added materials. Its raw materials include phenol, formaldehyde and sodium hydroxide, wherein 0.2 mol of phenol, 0.5 mol of formaldehyde and 0.06 mol of sodium hydroxide are added.

[0070] A preparation method for preparing a water-soluble phenolic resin by adjusting the addition mode and reaction temperature of the added materials, the specific steps are as follows:

[0071] (1) Preheat and melt the phenol first, weigh the phenol in a four-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer according to the molar ratio of phenol, formaldehyde, and sodium hydroxide of 1:2.5:0.3, and turn on the electric Stirrer and water bath heating;

[0072] (2) Raise the temperature gradually and add 2 / 3 of the catalyst sodium hydroxide at the same time until the temperature rises to 50°C ...

Embodiment 2

[0076] In the embodiment of the present invention, a synthesis process for preparing water-soluble phenolic resin is determined by adjusting the addition method and reaction temperature of the added materials. Its raw materials include phenol, formaldehyde and sodium hydroxide, wherein 0.2 mol of phenol, 0.4 mol of formaldehyde and 0.06 mol of sodium hydroxide are added.

[0077] A preparation method for preparing a water-soluble phenolic resin by adjusting the addition mode and reaction temperature of the added materials, the specific steps are as follows:

[0078] (1) Preheat and melt the phenol first, weigh the phenol in a four-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer according to the molar ratio of phenol, formaldehyde, and sodium hydroxide of 1:2.0:0.3, and turn on the electric Stirrer and water bath heating;

[0079] (2) Raise the temperature gradually and add 2 / 3 of the catalyst sodium hydroxide at the same time until the te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap