Hydrogen discharging water seal tank capable of automatic water supplementing

A technology of automatic water replenishment and water sealing tank, applied in hydrogen technology, electrolysis process, pipeline system, etc., can solve problems such as manual water replenishment and hidden safety hazards, and achieve the effect of simple structure, excellent effect and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

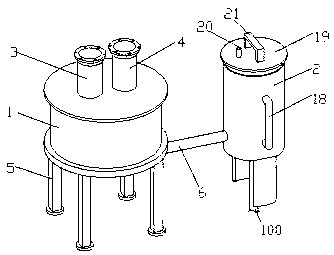

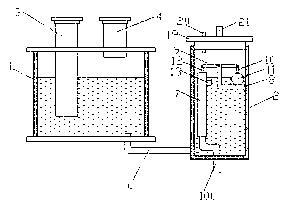

[0028] Embodiment 1 introduces a hydrogen-expelling water seal tank with automatic water replenishment. The main structure includes a water seal tank 1, a water level balance tank 2, a hydrogen gas inlet pipe 3 and a hydrogen gas discharge pipe 4. In the water seal tank 1 and the water level balance tank 2 The lower surface of each is provided with legs 5, which can prevent it from corroding in contact with the effusion on the ground. A communication pipe 6 is arranged between the water seal tank 1 and the water level balance tank 2 , and the left and right ends of the communication tube 6 are connected to the bottoms of the water seal tank 1 and the water level balance tank 2 . The water seal tank 1 and the water level balance tank 2 are equipped with the water seal liquid with the same liquid level through the action of the connecting pipe 6, and the hydrogen gas inlet pipe 3 extends below the water seal liquid, and the hydrogen gas outlet pipe 4 is arranged in the water seal...

Embodiment 2

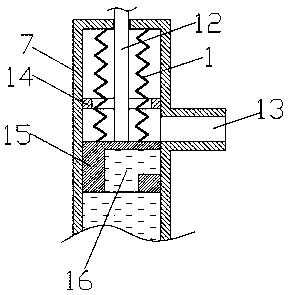

[0032] Embodiment 2 introduces a hydrogen-expelling water-sealed tank with automatic water replenishment that can adjust the liquid level. Its main structure is the same as that of Embodiment 1, and the same parts are not specifically described in Embodiment 2. Attached below Figure 5 And attached Figure 6 The improved part of embodiment 2 is described in detail:

[0033] Implementation 2. Rotating support 8 is provided with two sections, and its two sections are respectively horizontal frame 801 and vertical frame 802. A plurality of threaded holes 803 are provided in the horizontal direction of horizontal frame 801. The lower end of vertical frame 802 is provided with The threaded hole 803 corresponds to the through hole, and a fixing bolt 804 is arranged between the threaded hole 803 and the through hole, and the two are fixedly connected by the action of the fixing bolt 804 . Also offer a plurality of circular holes 901 on the horizontal direction of the rotating bar 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com