Lifting type sand washing and stone milling mechanism

A lift type and lifter technology, which is applied in the direction of textile and paper making, roughening, fabric surface trimming, etc., can solve the problems of stable work and good sand washing effect, so as to improve the stability of sand washing, good sand washing effect and improve work stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

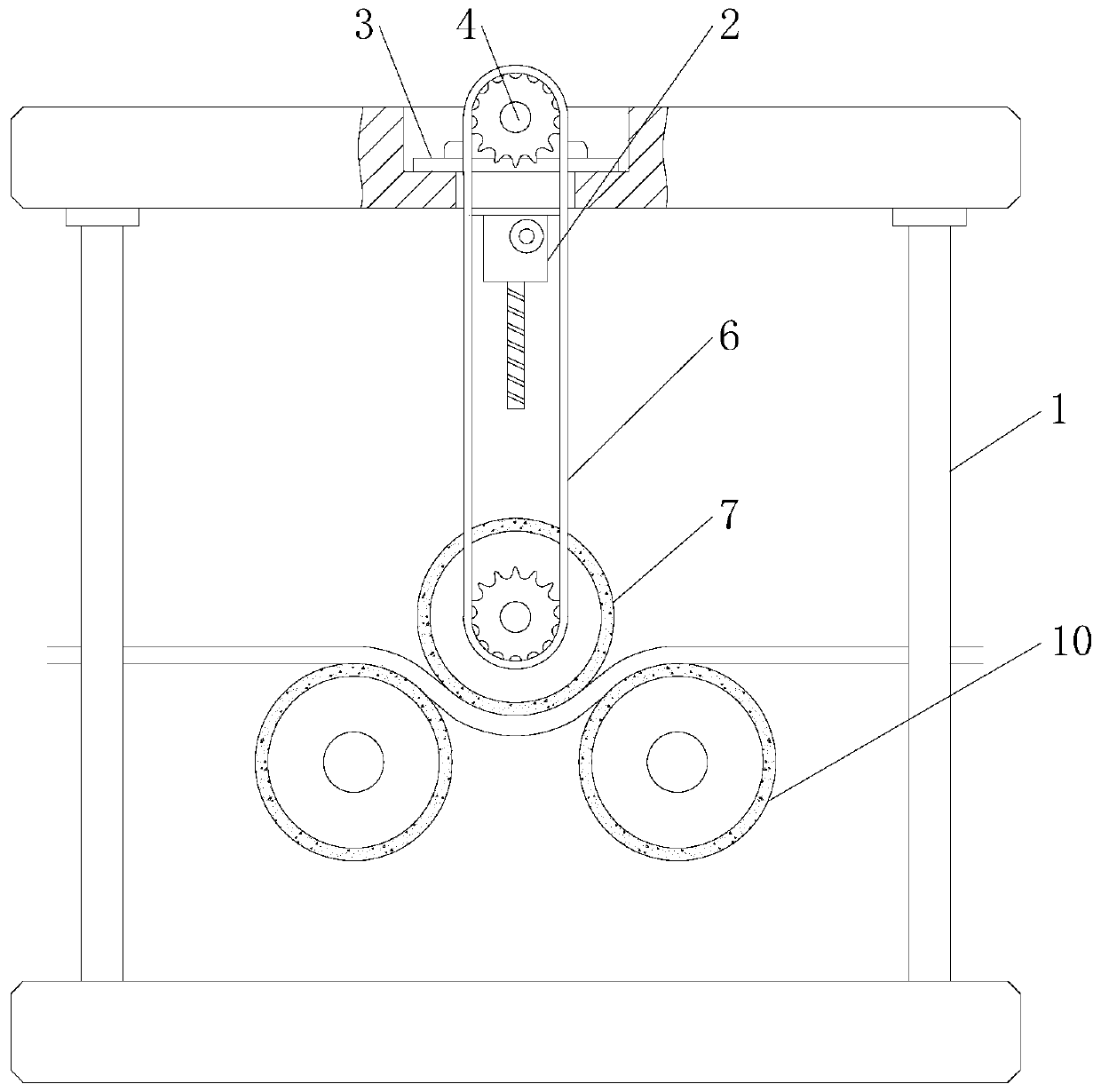

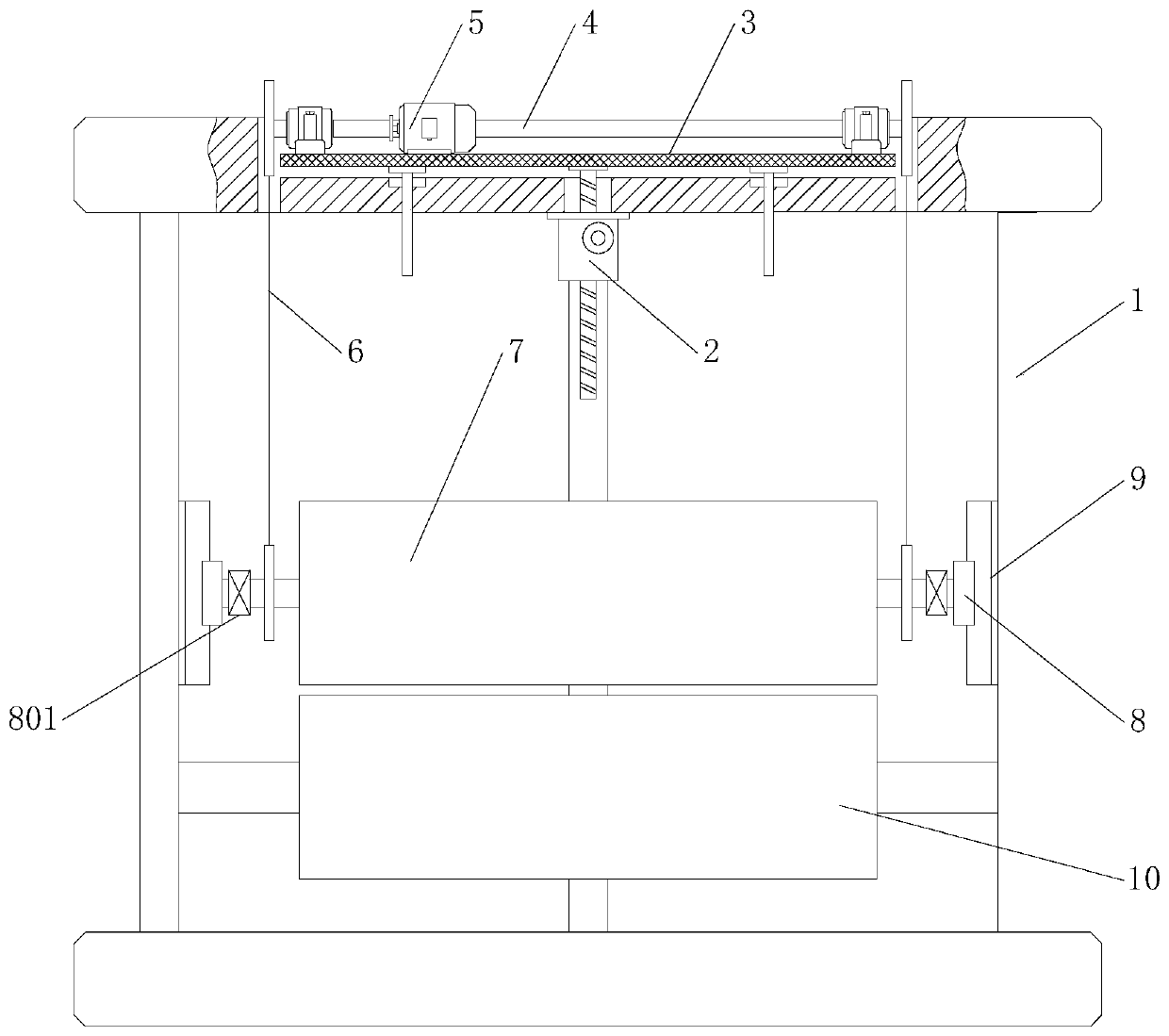

[0015] Example. A lifting type sand washing stone mill mechanism, constituted as figure 1 Shown, comprise sand washing frame 1, the top of sand washing frame 1 is connected with lifting seat 3 through screw lifter 2, and lifting seat 3 is provided with drive sprocket 4, and drive sprocket 4 middle part is connected with driving motor 5 through belt pulley, The outside of driving sprocket 4 is connected with first sand washing wheel 7 through drive chain 6, and first sand washing wheel 7 is positioned at the bottom of driving sprocket 4, and the two ends of first sand washing wheel 7 are connected with sand washing frame 1 through guide assembly; The guide assembly includes a guide shoe 8 rotatably connected to the end of the first sand washing wheel 7 , and a guide rail 9 fixed on the side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com