Cast-in-place pile construction method adopting pre-reinforcing and then hole forming for easy-to-collapse stratum

A construction method and pre-reinforcement technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as poor self-stability of geological conditions, difficulty in forming holes for cast-in-situ piles, and over-square concrete pouring, so as to improve construction efficiency, The effect of improving the quality of pore formation and increasing the efficiency of pore formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

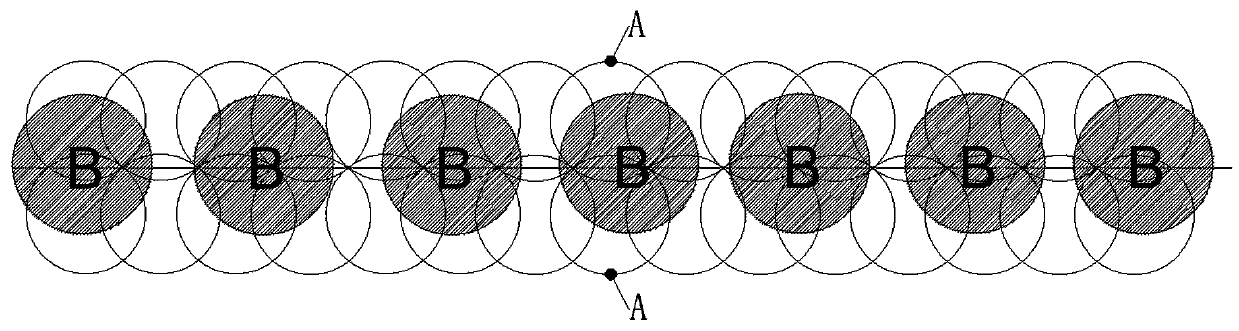

[0034] Such as figure 1 Shown, a kind of collapsible stratum pre-reinforcement of the present invention forms the construction method of perforated pile again, carries out according to the following steps:

[0035] (1) Determination of the depth range of bored pile collapse;

[0036] Combined with the geological survey situation, find out the range of weak soil layers with poor self-stability, easy to collapse when exposed to water, and relatively loose, that is, the range of the collapse depth of bored piles:

[0037] A) Combined with the actual drilling situation on site, roughly determine the depth of the collapsed hole by observing the amount of soil lifte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap