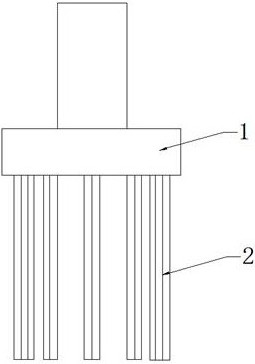

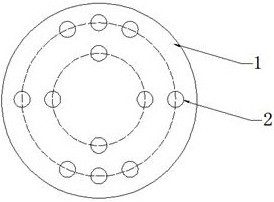

Small pile foundation construction method

A technology of pile foundation and construction method, which is applied in the direction of foundation structure engineering, sheet pile wall, drilling equipment and methods, etc., to achieve the effects of reduced material consumption and loss, small impact of terrain, and enhanced adaptability of ground stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of small pile foundation construction method of the present invention comprises the steps:

[0036] Rock drill positioning: Use GPS to locate the center point of the pile foundation and mark it. After the positioning plate of the rock drill is aligned with the mark, start the hydraulic arm, press and fix the positioning plate, and complete the alignment.

[0037] Start footage: Turn on and start the air compressor, start the main force, start the hydraulic system, and the drill bit starts to drill the footage.

[0038] Hole cleaning during the process: The dross and dust generated during the rock drilling process are collected by the hydraulic dust suction device to prevent pollution. At the same time, the main drill pipe is lifted up and down reciprocally to clear the hole.

[0039] Reach the design hole depth: When the design hole depth is expected to be reached, use the measuring rope to re-measure the depth. Generally, the drilling depth is about 10 cm long...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap