Construction method of supporting bolts for deep foundation pit under high pressure

A technology for foundation pit support and bolt construction, which is applied in foundation structure engineering, excavation, sheet pile wall, etc. The effect of reducing the volume loss, avoiding the collapse of the hole wall, and solving the problem of hole formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

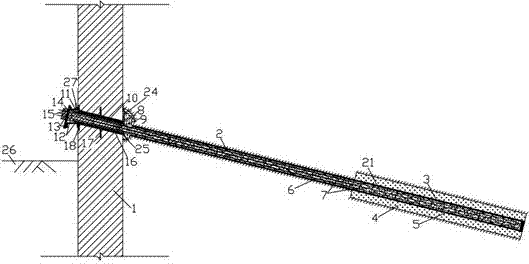

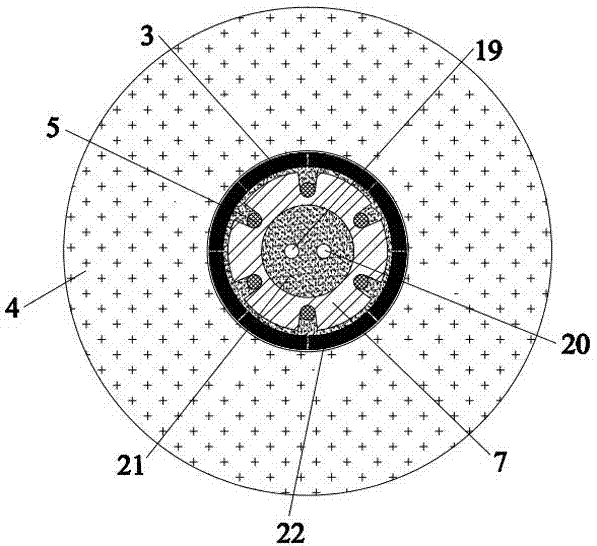

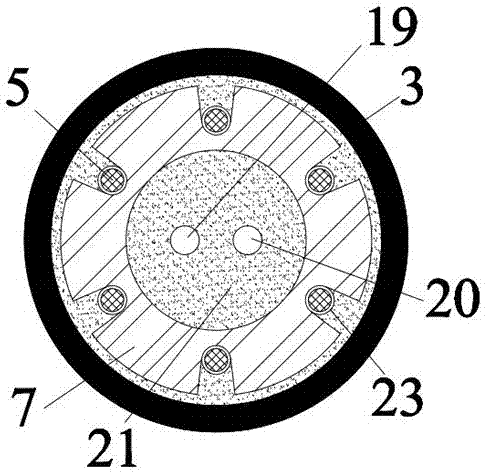

[0041] refer to Figure 1-5 As shown, in the high pressure water depth foundation pit supporting anchor structure of the present invention, one end is arranged on the underground diaphragm wall 1, and the other end is fixed in the soil body for supporting the underground diaphragm wall 1, including PVC casing and being arranged on the PVC Anchor cables 5, primary grouting pipes 19, secondary high-pressure grouting pipes 20 and anchor rod grouting body 21 in the casing, anchor cables 5, primary grouting pipes 19, secondary high-pressure grouting pipes 20 and their lengths extend underground Outside the continuous wall 1, the anchor rod grouting body 21 is formed by grouting from the bottom to the top with the primary grouting pipe 19.

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap