Self-cleaning mechanical scraper knife of scraping machine

A technology of mechanical shovels and shovels, which is applied in the field of self-cleaning shovel mechanical shovels, which can solve the problems of easily smaller shovels, difficulty in discharging materials, and insufficient sharpness of shoveling soil, so as to facilitate material discharge and improve cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

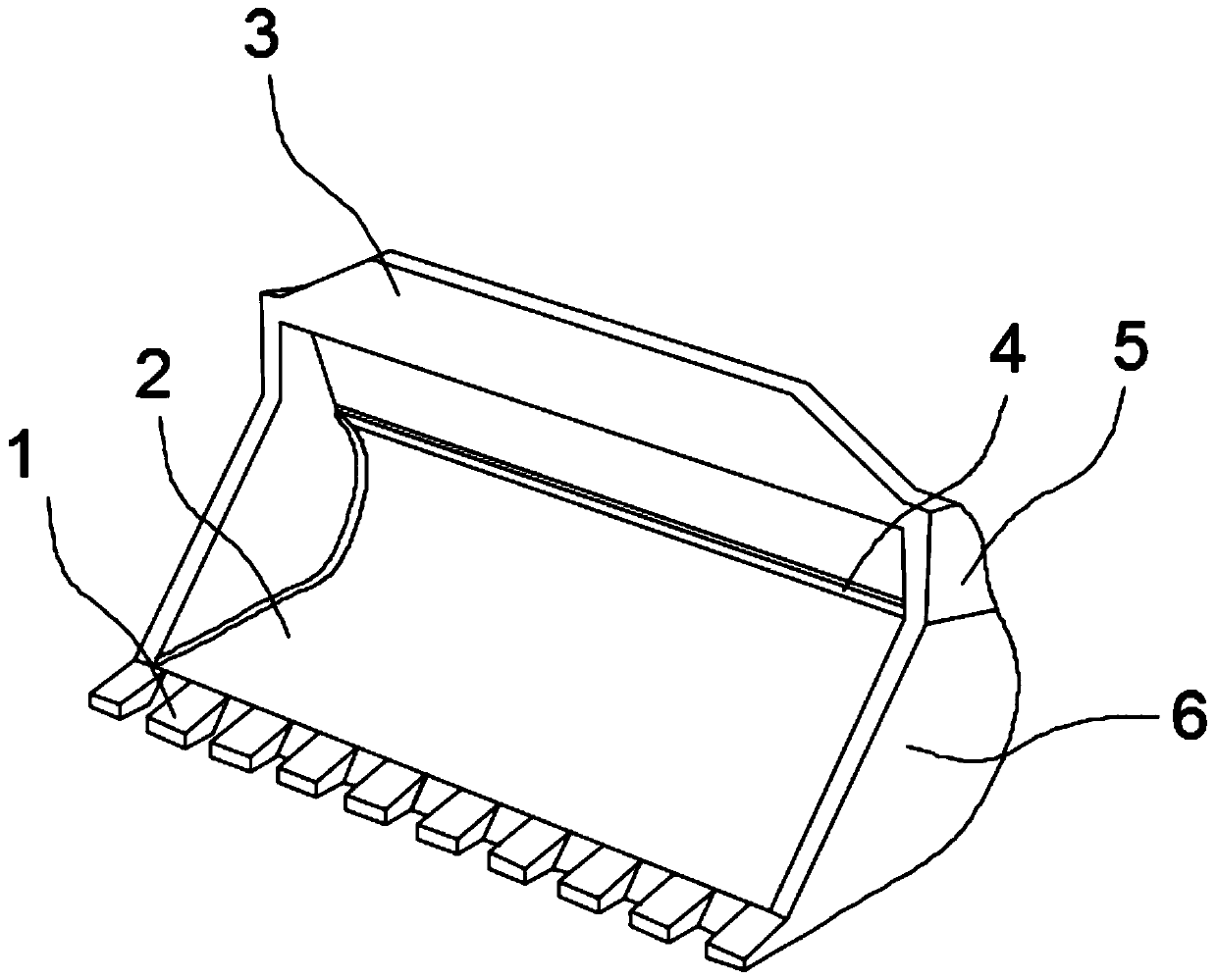

[0034] Shovel is a machine used for digging and transporting soil. The soil scraped by the scraper can be automatically loaded into the bucket and transported away. It uses a bucket to excavate materials above or below the bearing surface, and load them into transport vehicles or unloaded to the earth-moving machinery of the stockyard. The excavated materials are mainly soil, coal, silt and pre-loose soil and rock.

[0035] When cleaning up some materials with high viscosity, such as soil and silt, they tend to stick to the blade. Squeezing slowly will cause the blade to become smaller. On the one hand, the shovel is not sharp and efficient, and on the other hand This will cause the scraped material to become smaller in volume and difficult to discharge. In the prior art, most of the manual cleaning is performed when not in use, which in turn causes the cleaning efficiency to decrease.

[0036] In view of the above problems, the present invention provides a self-cleaning mechanica...

Embodiment 2

[0047] The embodiment of the present invention is further defined on the basis of embodiment 1.

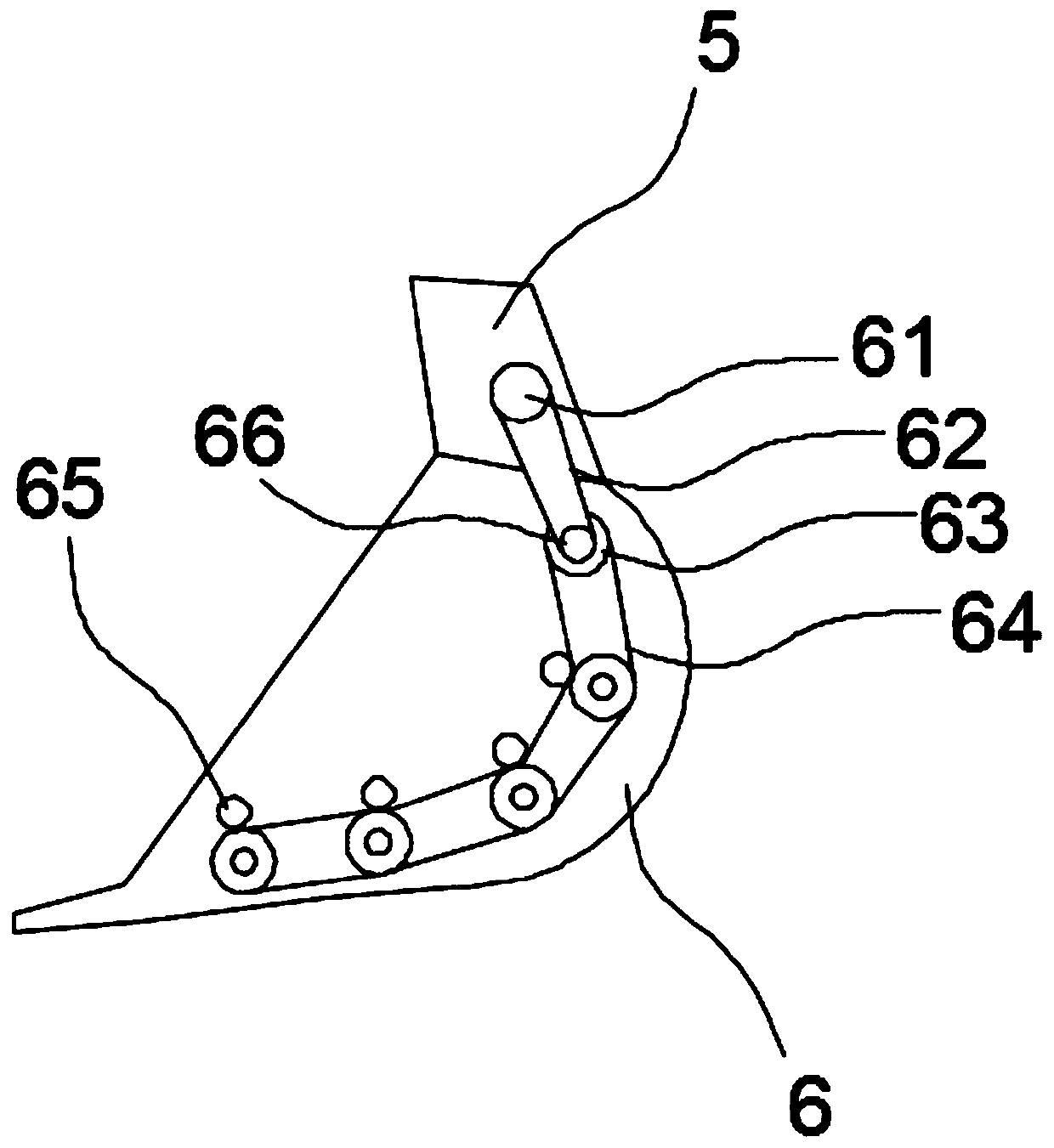

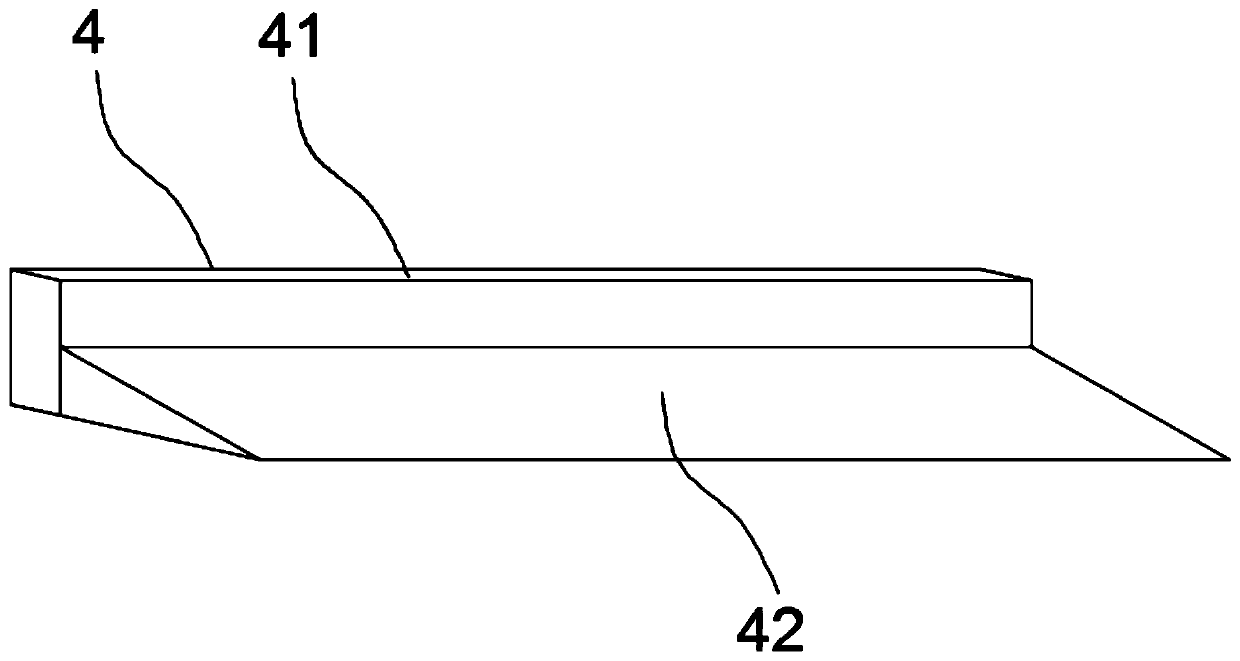

[0048] See Figure 3-5 A fixing plate 41 is fixed on the cleaning shovel structure 4 in cooperation with the shovel platform 42, and the cross section of the shovel platform 42 is triangular.

[0049] The shovel platform 42 is provided with a bottom support plate 46, and a bottom plate 43 is fixed at the bottom of the bottom support plate 46, a movable plate 44 is hinged on the bottom plate 43, and a buffer layer 45 is provided between the movable plate 44 and the bottom support plate 46 The buffer layer 45 is composed of a plurality of elastic members 47 distributed at equal intervals.

[0050] Furthermore, the movable plate 44 can change its angle through the buffer layer 45 so as to be suitable for cleaning residues of different thicknesses and improve the cleaning effect.

[0051] Optimally, the elastic member 47 is hinged between the movable plate 44 and the bottom support plate 46,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com