Long-distance vertical floating support shafting structure

A floating support, long-distance technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of poor rotor dynamic performance, material waste, etc., and achieve the effect of reducing vibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

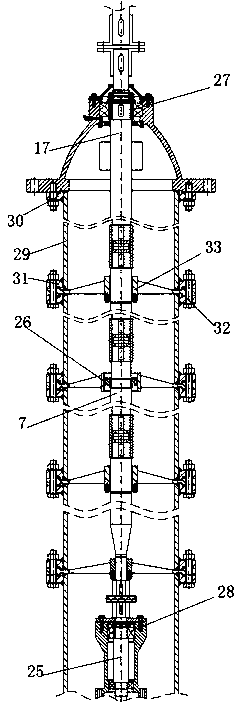

[0040] Please refer to Figure 1-4 As shown, a long-distance vertical floating support shafting structure includes a positioning adjustment structure 27, a number of floating support structures 26 and a short shaft structure 28, and also includes a first shaft 17, a number of second shafts 7 and a third shaft 25 , the first shaft 17, several second shafts 7 and the third shaft 25 are sequentially connected, and the several second shafts 7 are connected end-to-end, the positioning adjustment structure 27 is sleeved on the first shaft 17, and the positioning adjustment structure 27 drives the first The first shaft 17 moves in the axial direction of the first shaft 17, the short shaft structure 28 is sleeved on the third shaft 25, and the short shaft structure 28 and the third shaft 25 are relatively stationary in the axial direction of the third shaft 25; The floating support structure 26 includes a rolling bearing 4, a bearing floating sleeve 3, a sliding key 6 and a floating b...

Embodiment 2

[0051] Please refer to Figure 1-4 As shown, this embodiment optimizes the design of the positioning adjustment structure 27 to achieve a better positioning adjustment effect.

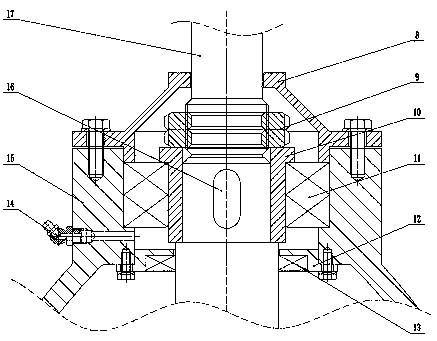

[0052] In the example, as image 3 As shown, the positioning adjustment structure 27 includes a first thrust bearing 11, a shaft sleeve 10 and a bearing housing 15. The shaft sleeve 10 is sleeved on the first shaft 17, and the first thrust bearing 11 is sleeved on the shaft sleeve 10. The outer ring of the first thrust bearing 11 is stationary relative to the bearing housing 15, and the inner ring of the first thrust bearing 11 is stationary relative to the shaft sleeve 10. The positioning adjustment structure 27 also includes an adjusting nut 9, which is sleeved on the first shaft. 17 , the adjusting nut 9 is located on the end surface of the sleeve 10 , and the adjusting nut 9 drives the first shaft 17 to move in the axial direction of the first shaft 17 relative to the axial direction. The adjustm...

Embodiment 3

[0058] Please refer to Figure 1-4 As shown, the present embodiment optimizes the design of the floating support structure 26 to achieve a better restriction and use effect on the second shaft 7 .

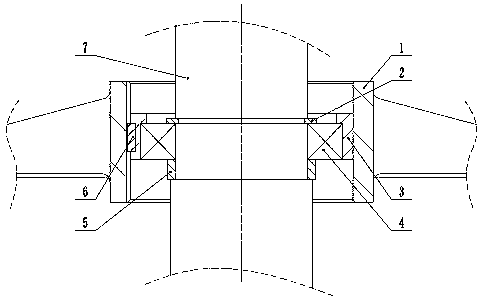

[0059] Such as figure 2 As shown, in this embodiment, the floating support structure 26 includes a rolling bearing 4, a bearing floating sleeve 3, a sliding key 6 and a floating bearing bracket 1, and several rolling bearings 4 are sleeved on a second shaft 7, and each second shaft 7 There is at least one rolling bearing 4, the inner ring of the rolling bearing 4 is relatively stationary to the second shaft 7, the bearing floating sleeve 3 is set on the outer ring of the rolling bearing 4, the bearing floating sleeve 3 and the outer ring of the rolling bearing 4 are relatively stationary, and the bearing floating sleeve 3 is connected with the sliding key 6, and the floating bearing bracket 1 is provided with a sliding groove, and the sliding key 6 and the sliding groove are nested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com