Direct current charging cable for charging automobile

A technology for DC charging and charging cars, which is applied in the field of cables and car charging cables. It can solve the problems of inconvenient adjustment of cable length, simple external structure, and poor storage effect, and achieve stable storage, high flexibility, and convenient storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

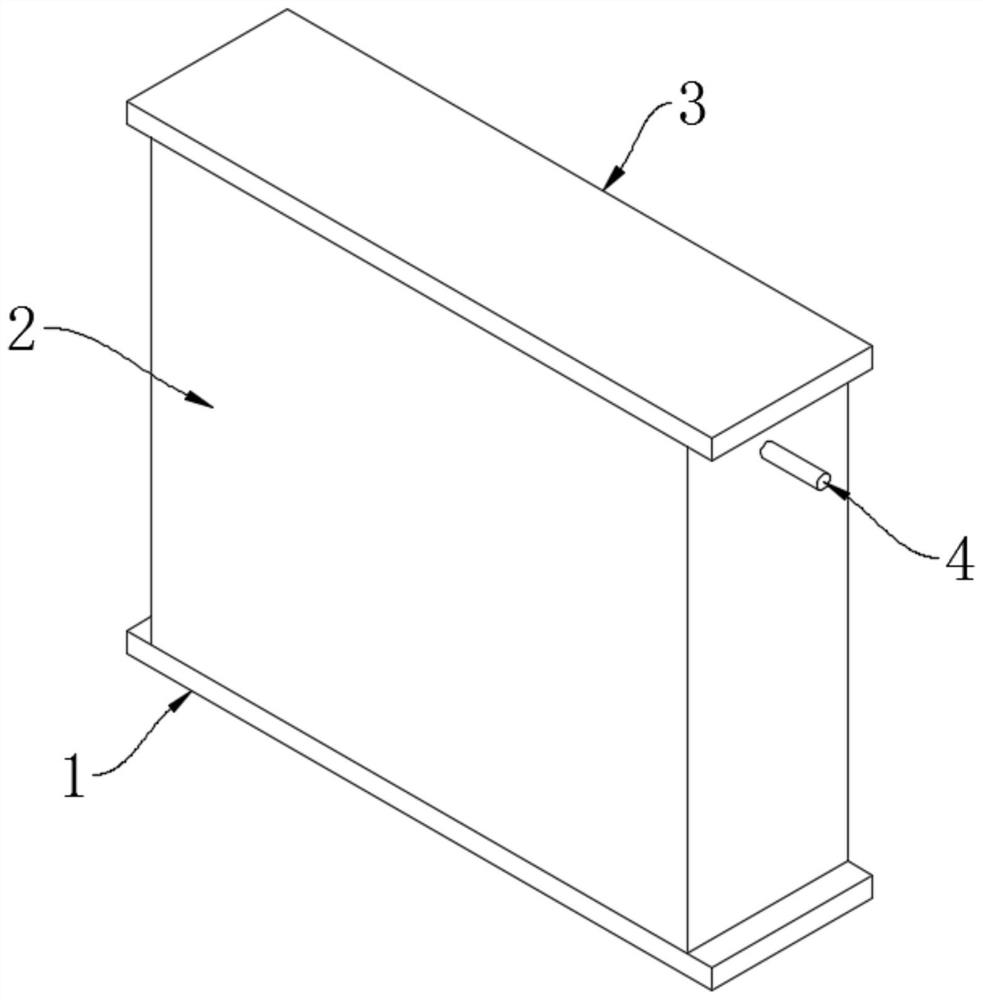

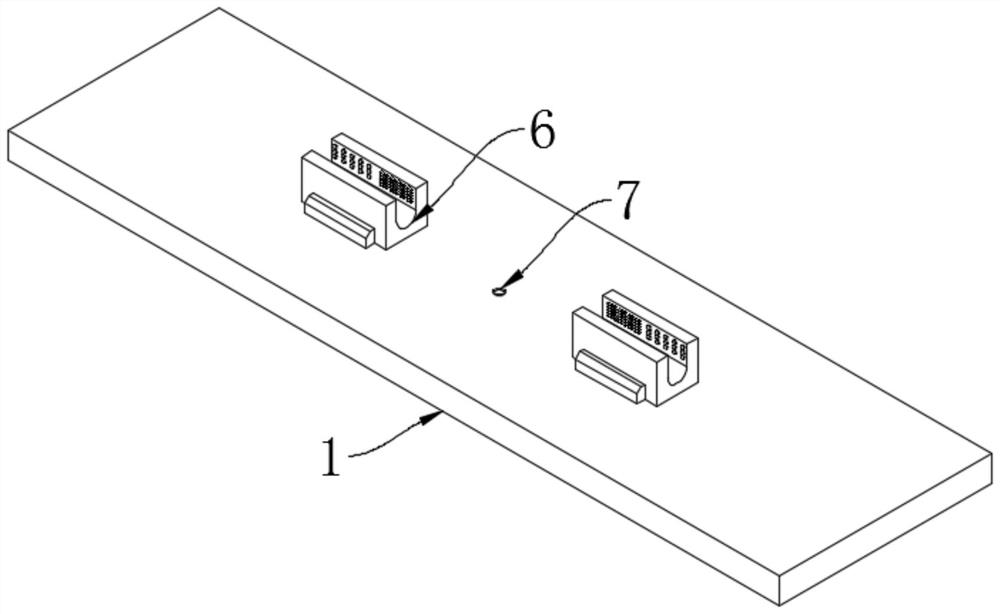

[0028] A DC charging cable for a charging vehicle, comprising a lower base 1, a lateral frame 2, an upper guard plate 3, a cable body 4, a lifting and rotating bidirectional cable winding assembly 5 and a cable surface cleaning mechanism 6, and the lateral frame 2 is welded on the bottom. Between the base 1 and the upper guard plate 3, a closed box is formed to effectively store the cable body 4 with excess length. The lifting and rotating bidirectional cable winding assembly 5 is fixedly installed at the bottom of the upper The cable body 4 is effectively stored, and can also be adjusted arbitrarily when the length of the cable body 4 needs to be adjusted, and the flexibility is higher. The cable surface cleaning mechanism 6 is fixedly installed on the top of the lower base 1, and the number of the cable surface cleaning mechanism 6 is two. The two cable surface cleaning mechanisms 6 are respectively located on both sides of the lifting and rotating two-way cable winding assem...

Embodiment 2

[0032] A DC charging cable for a charging vehicle, comprising a lower base 1, a lateral frame 2, an upper guard plate 3, a cable body 4, a lifting and rotating bidirectional cable winding assembly 5 and a cable surface cleaning mechanism 6, and the lateral frame 2 is welded on the bottom. Between the base 1 and the upper guard plate 3, the lifting and rotating bidirectional cable winding assembly 5 is fixedly installed at the bottom of the upper guard plate 3, the cable surface cleaning mechanism 6 is fixedly installed on the top of the lower base 1, and the number of the cable surface cleaning mechanism 6 For two, two cable surface cleaning mechanisms 6 are located on both sides of the lifting and rotating bidirectional cable winding assembly 5 respectively.

[0033] In this embodiment, on the basis of Embodiment 1, the internal layout of the lateral frame 2 is embodied, such as Figure 4 As shown, one side of the lifting and rotating bidirectional cable winding assembly 5 is f...

Embodiment 3

[0036] A DC charging cable for a charging vehicle, comprising a lower base 1, a lateral frame 2, an upper guard plate 3, a cable body 4, a lifting and rotating bidirectional cable winding assembly 5 and a cable surface cleaning mechanism 6, and the lateral frame 2 is welded on the bottom. Between the base 1 and the upper guard plate 3, the lifting and rotating bidirectional cable winding assembly 5 is fixedly installed at the bottom of the upper guard plate 3, the cable surface cleaning mechanism 6 is fixedly installed on the top of the lower base 1, and the number of the cable surface cleaning mechanism 6 For two, two cable surface cleaning mechanisms 6 are located on both sides of the lifting and rotating bidirectional cable winding assembly 5 respectively.

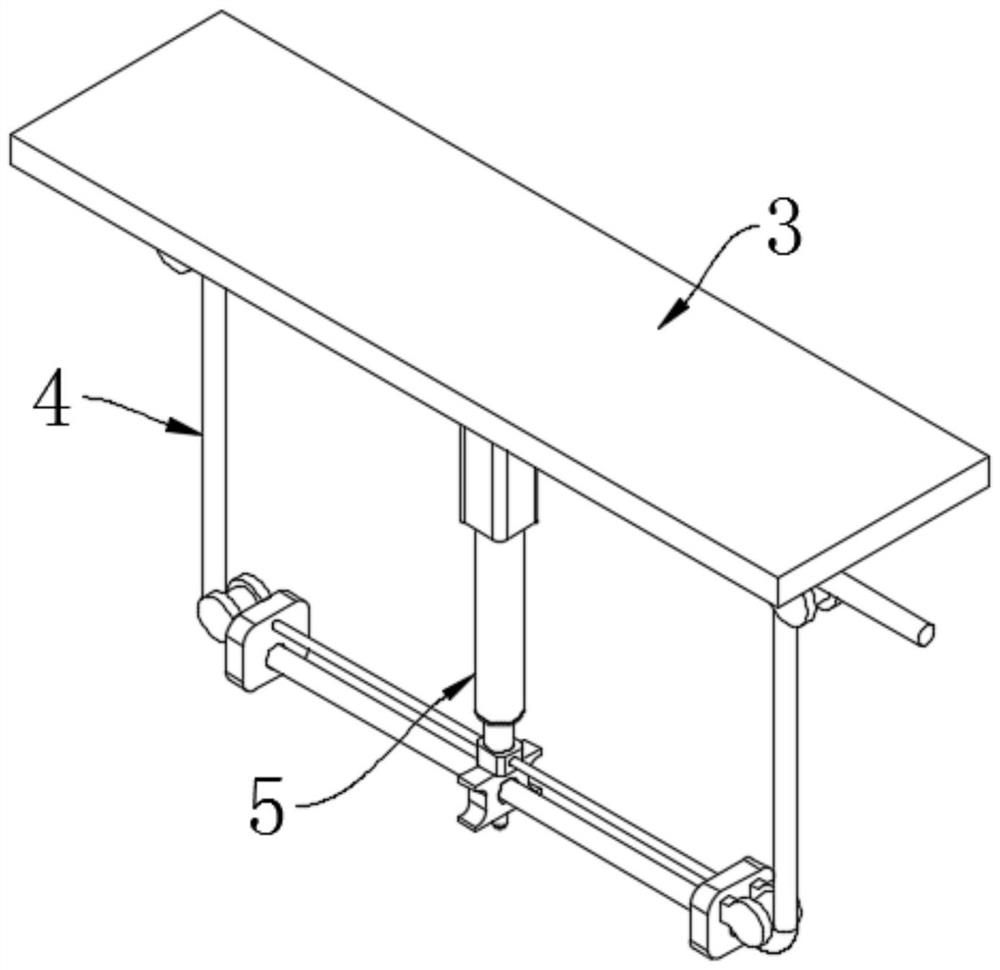

[0037] This embodiment embodies the structure of the lifting and rotating bidirectional cable winding assembly 5 on the basis of the above-mentioned embodiment, such as Figure 5 As shown, the lifting and rotating bidir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com