Hydraulic stepless speed change power wheel

A continuously variable speed, power wheel technology, used in transmissions, portable lifting devices, belts/chains/gears, etc., can solve problems such as inability to apply high-power vehicles, complex structures, and increased gear positions, to prevent oil circuit entanglement. , the effect of slowing down the negative impact and compressing the overall space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] In the following description, specific details are set forth in order to provide a thorough understanding of the present invention. However, the present invention can be implemented in many other ways than those described here, and those skilled in the art can make similar extensions without departing from the connotation of the present invention. Accordingly, the present invention is not limited to the specific embodiments disclosed below.

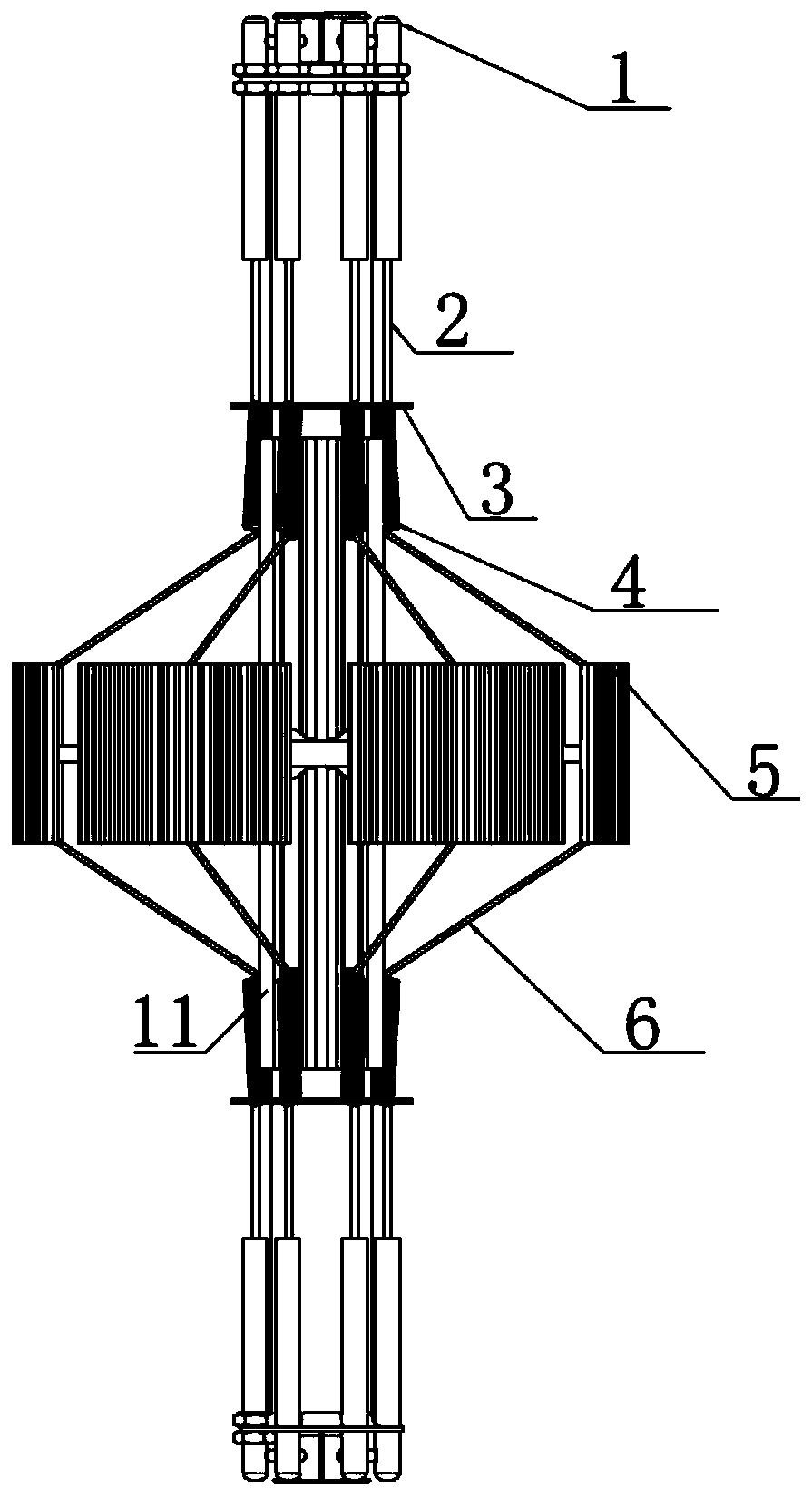

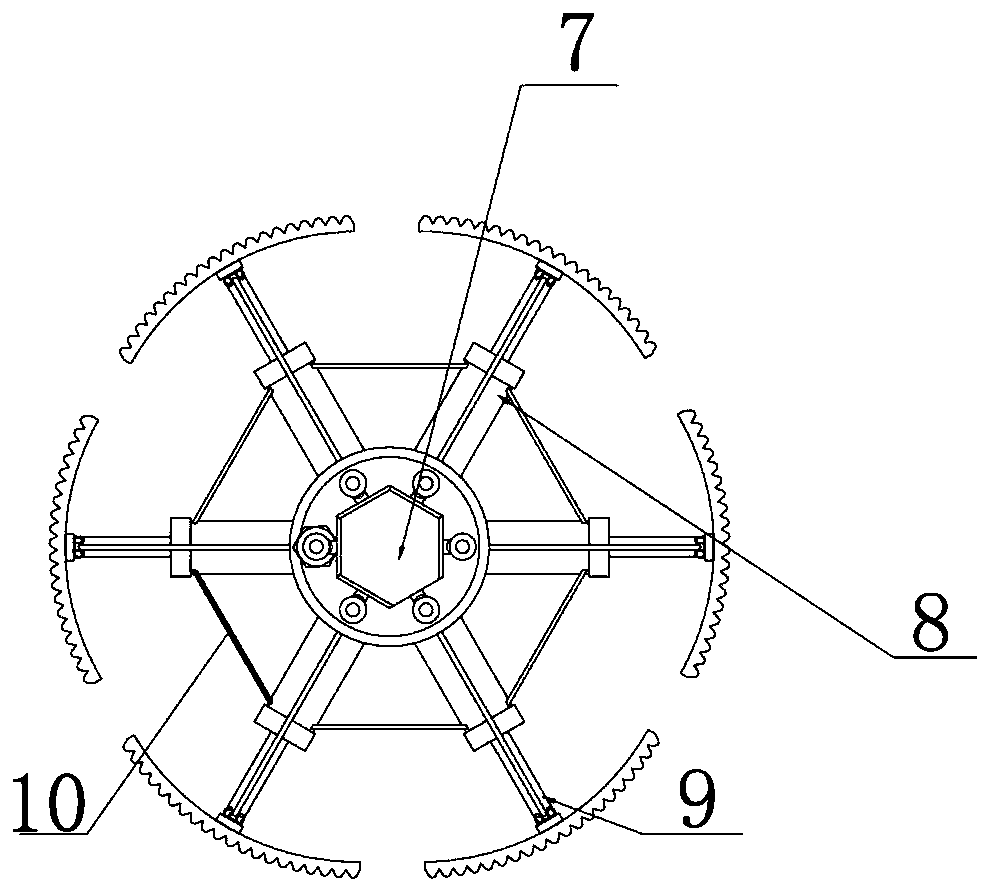

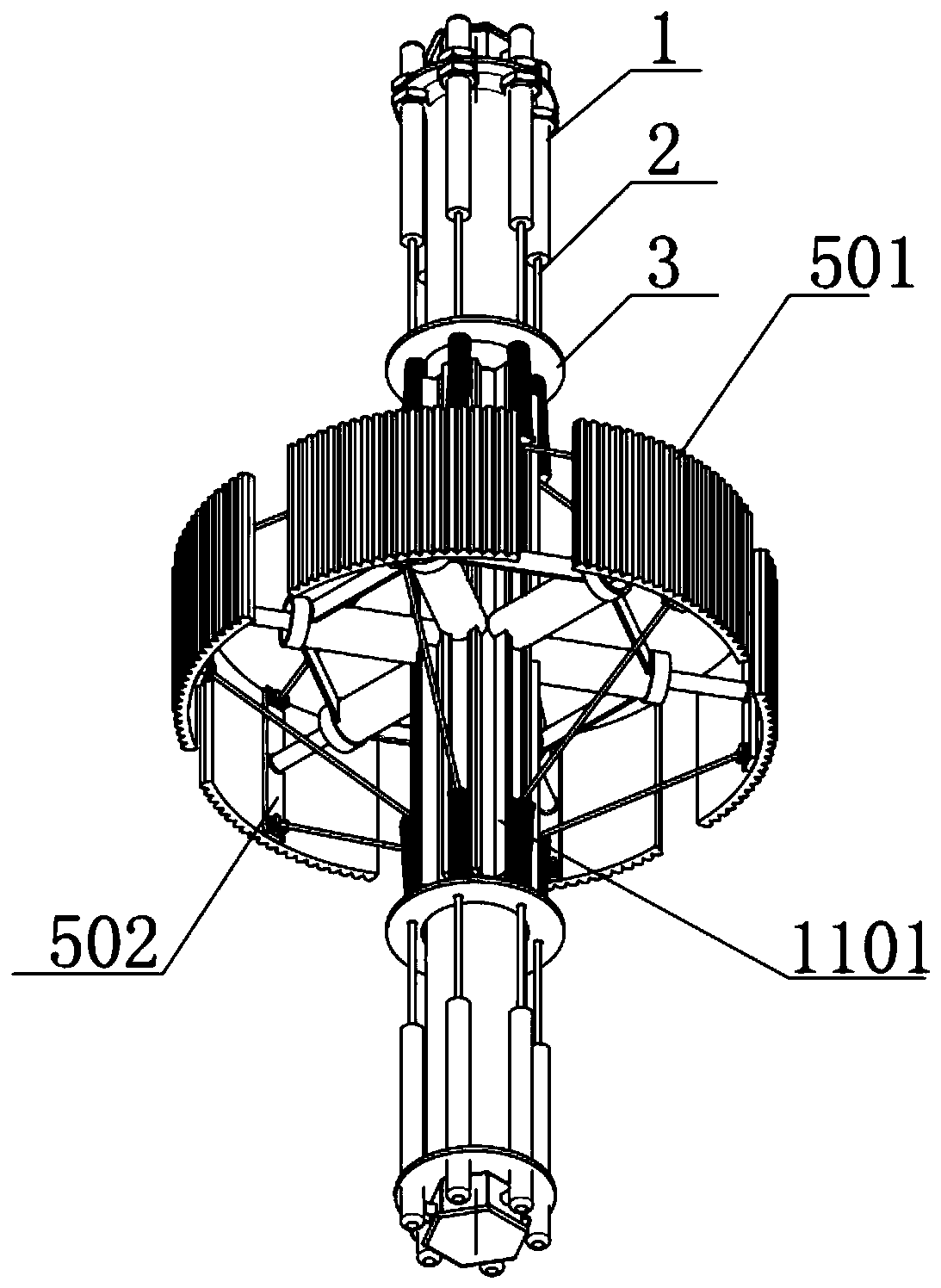

[0025] Figure 1 to Figure 3 The hydraulic continuously variable speed power wheel according to the present invention includes a slide bar 11 and active hydraulic pushing mechanisms respectively arranged at both ends of the slide bar 11. The slide bar 11 is provided with a driven hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com