Spray header and cold rolling system to prevent dripping

A dripping and collecting tube technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems affecting the surface quality of finished products, polluting the surface of strip steel, etc., and achieve the effect of improving surface quality and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

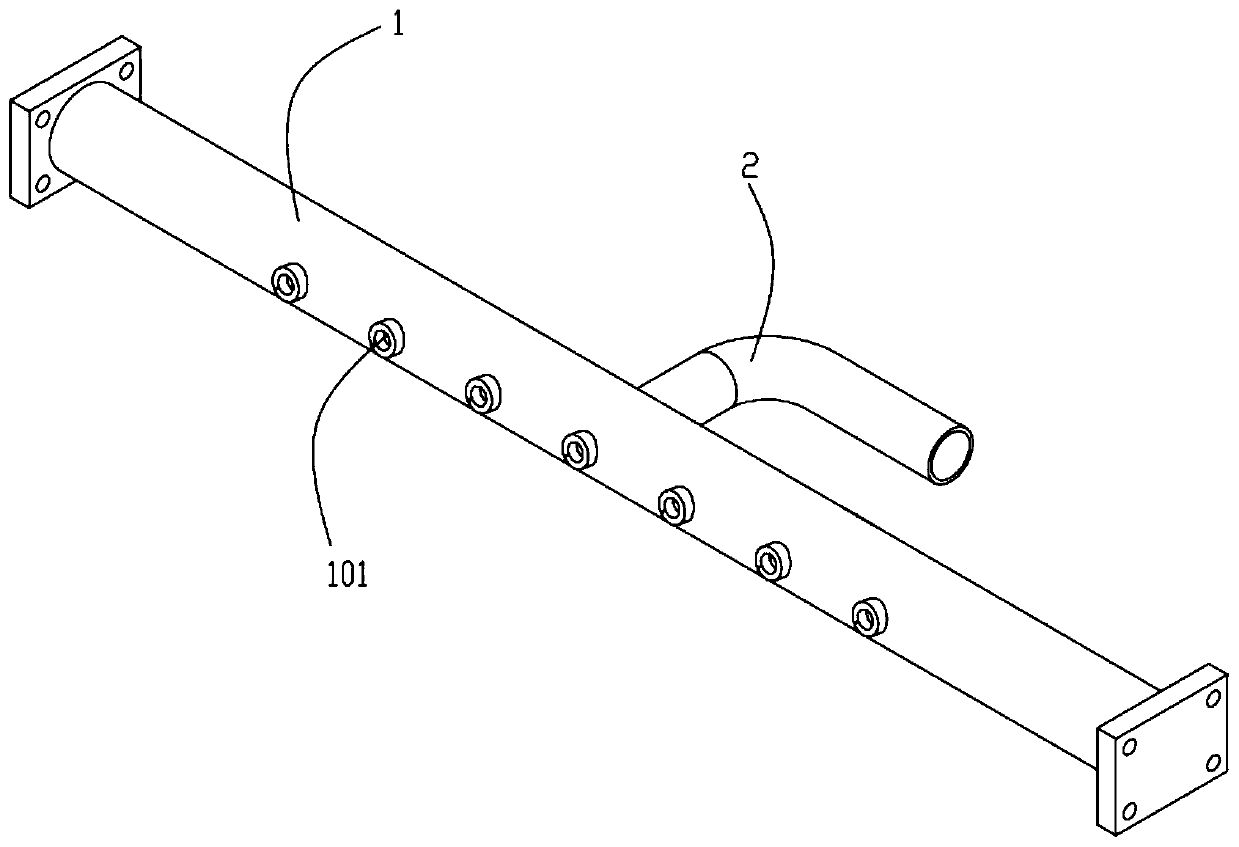

[0024] like figure 1 , is a conventional jetting header, which includes a header 1, which is connected to a header liquid inlet pipe 2, and which is provided with at least one nozzle 101, which can spray the liquid in the tube to a predetermined area The nozzle 101 can be a nozzle hole of a specific shape that can play a role in spraying liquid and is directly processed on the body of the header 1, or a nozzle can be installed on the nozzle 101.

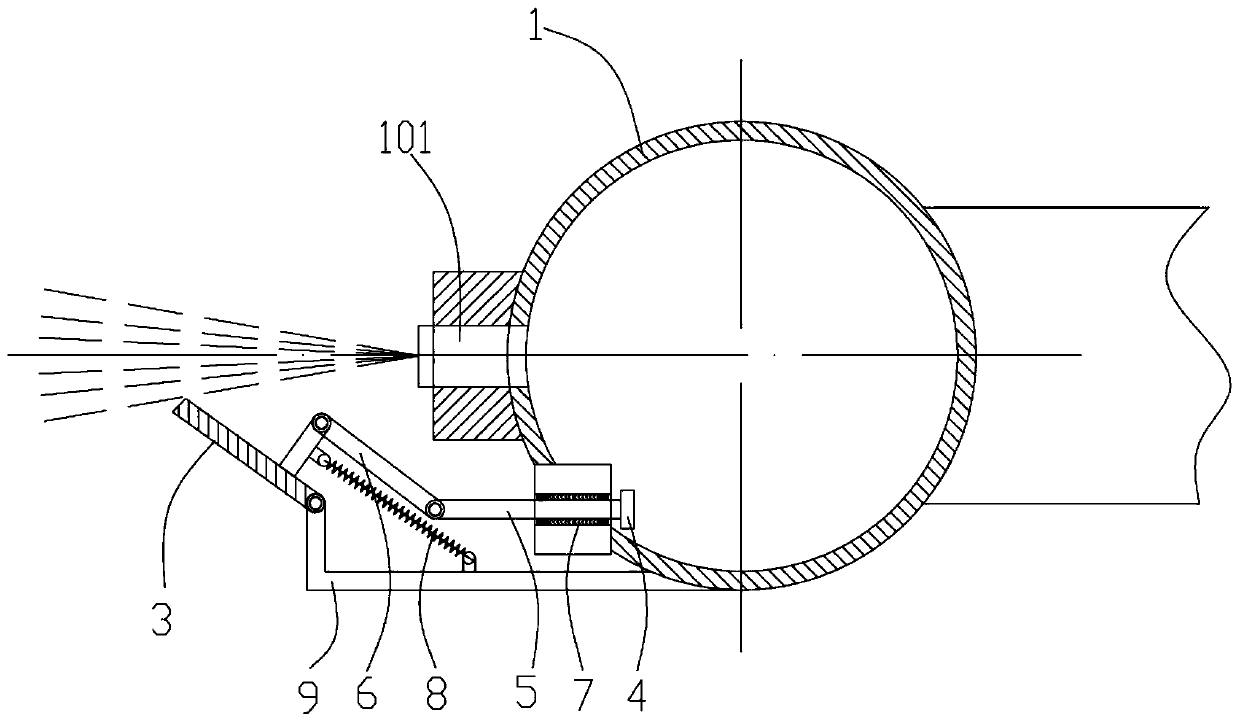

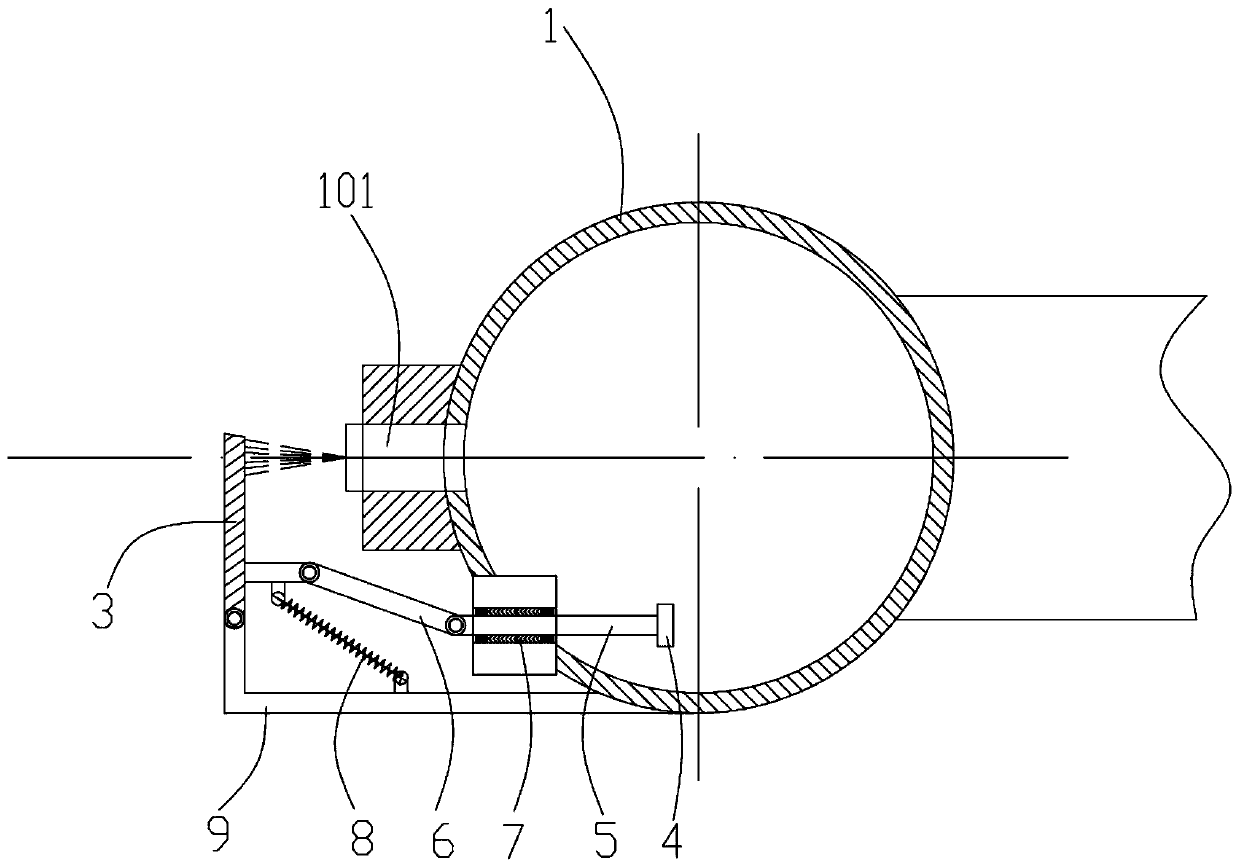

[0025] like figure 2 and image 3 , the embodiment of the present invention provides a spray header for preventing dripping, which is modified on the basis of the above-mentioned conventional spray header, including: a liquid baffle 3 is arranged on the outside of each of the nozzles 101, and each of the baffles The liquid plates 3 are all connected with a drive mechanism that drives itself to switch between the working position and the non-working position. In the non-working position, the liquid baffle plate 3 blocks the liquid...

Embodiment 2

[0038] The embodiment of the present invention relates to a cold rolling system, in which a spray header for spraying process lubricating fluid is arranged on the entrance side and / or exit side of the rolling mill, generally the spray header is arranged on both the entrance side and the exit side of the rolling mill, and Each side is provided with at least one injection header respectively above and below the strip running channel, which is easily determined by those skilled in the art according to the actual situation, and the installation position of the injection header is a conventional technology in the art, and will not be described in detail here . Preferably, each of the spraying headers adopts the spraying header for preventing dripping provided in the first embodiment above, and the specific structure of the spraying header for preventing dripping will not be repeated here.

Embodiment 3

[0040] This embodiment further describes the above-mentioned cold rolling system, which includes a rolling mill, a coiler and a cleaning device arranged between the rolling mill and the coiler, and the cleaning device is optimized as follows:

[0041] like Figure 4-Figure 6 , the embodiment of the present invention provides a floating strip surface cleaning roller, which can be used as the above-mentioned cleaning device, which includes a roll base 200 and a flexible floating roll 400, and the roll base 200 is connected with a The driving mechanism of the running channel; generally, the above-mentioned flexible floating roller 400 is arranged above the strip steel running channel to clean the upper surface of the strip steel 500, then the above-mentioned driving mechanism 300 can drive the roller seat 200 to lift, thereby driving the floating roller 400 lift. Further preferably, the bottom of the roller seat 200 is provided with a floating groove 201 with the notch facing do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com