Combustion device capable of automatically adjusting fuel feeding amount

A technology of fuel feeding and combustion device, which is applied in the direction of adjusting fuel supply, combustion method, and control of combustion. It can solve problems such as cumbersome process, low work efficiency, and safety issues, and achieve the effect of sufficient combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

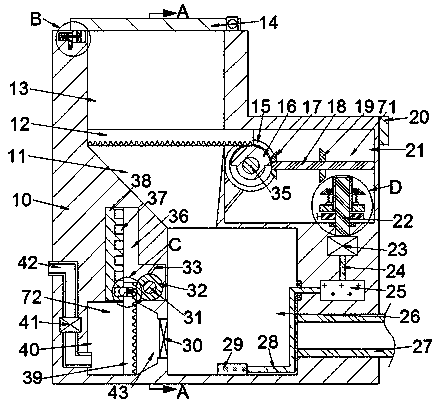

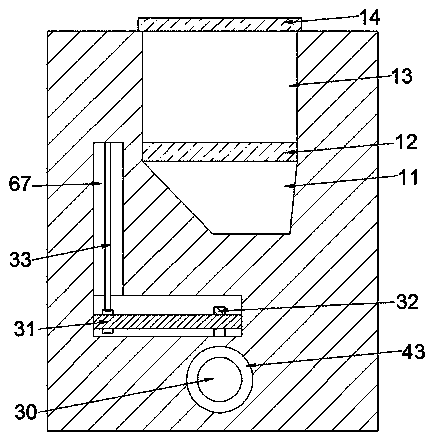

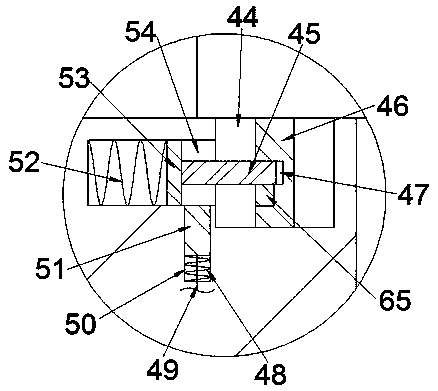

[0019] Such as Figure 1-5 As shown, a combustion device that can automatically adjust the fuel feed includes a work box 10 and a contact button 20 fixedly connected to the outer end surface on the right side of the work box 10, and the contact button 20 can adjust the fuel feed. The working box 10 is provided with an upwardly opening feed chamber 13, which is filled with the fuel required for combustion, and the upper and outer end faces of the working box 10 are hinged to close the The closing plate 14 on the upper mouth of the feed chamber 13, the combustion chamber 26 positioned at the lower right side of the feed chamber 13 is fixed in the working box 10, and the combustion chamber 26 and the feed chamber 13 pass through the first The through hole 11 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap