Bearing residual life prediction method based on ternary Wiener process

A technology of life prediction and Wiener process, which can be used in complex mathematical operations and other directions, and can solve problems such as low prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

[0055] refer to Figure 1 to Figure 6 , a method for predicting the remaining life of a bearing based on a ternary Wiener process, the method comprising the following steps:

[0056] S1. Collect vibration signals and a temperature signal in two mutually perpendicular directions during the bearing degradation stage;

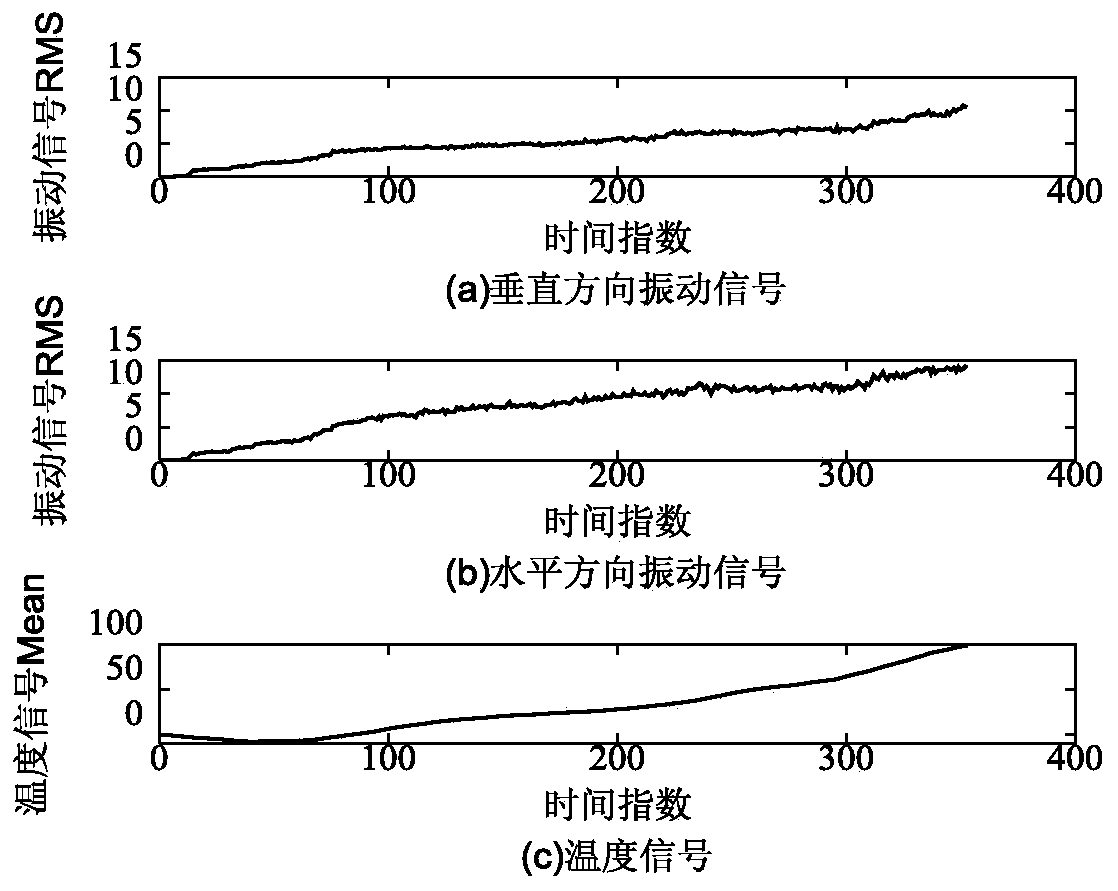

[0057] S2. Calculate the effective value of the vibration signal and the average value of the temperature signal in two directions, and construct three performance indicators representing the healthy state of the bearing (as attached figure 1 Shown), based on these three performance indicators for subsequent steps;

[0058]

[0059]

[0060]

[0061] S3. Test and analyze the three constructed performance indicators, and determine whether the Wiener process can be used to describe their degradation process;

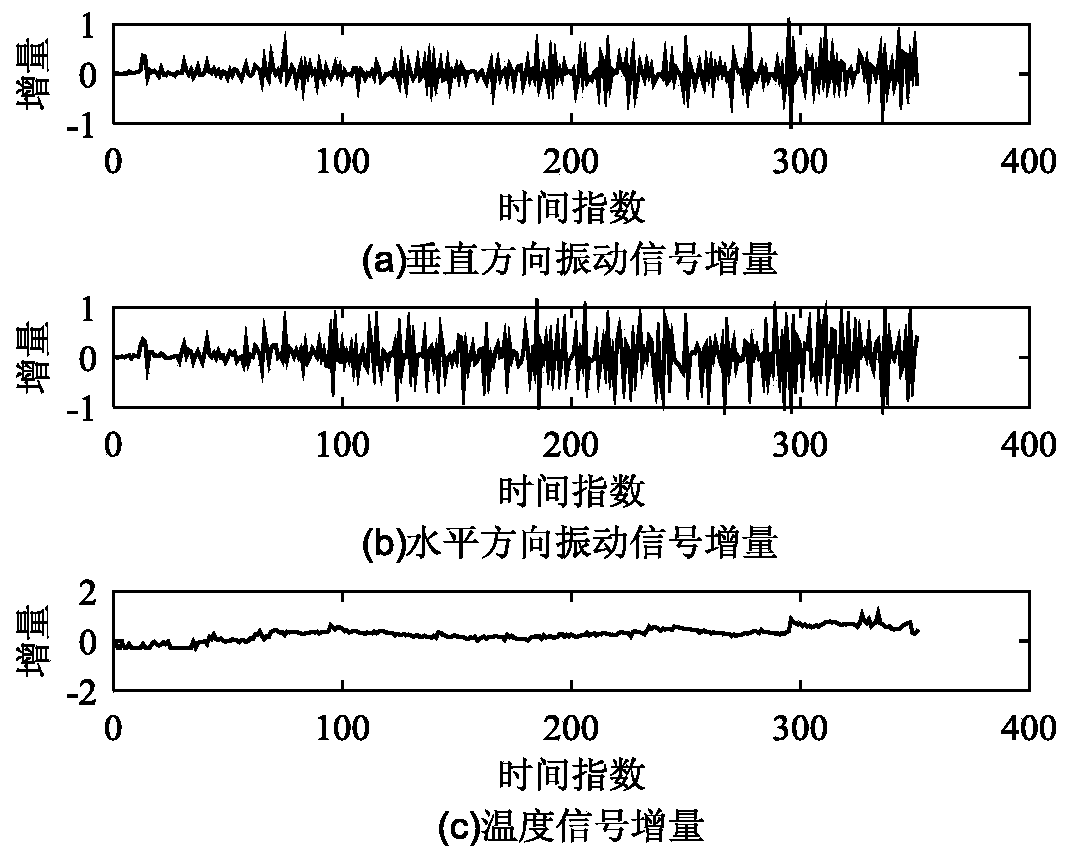

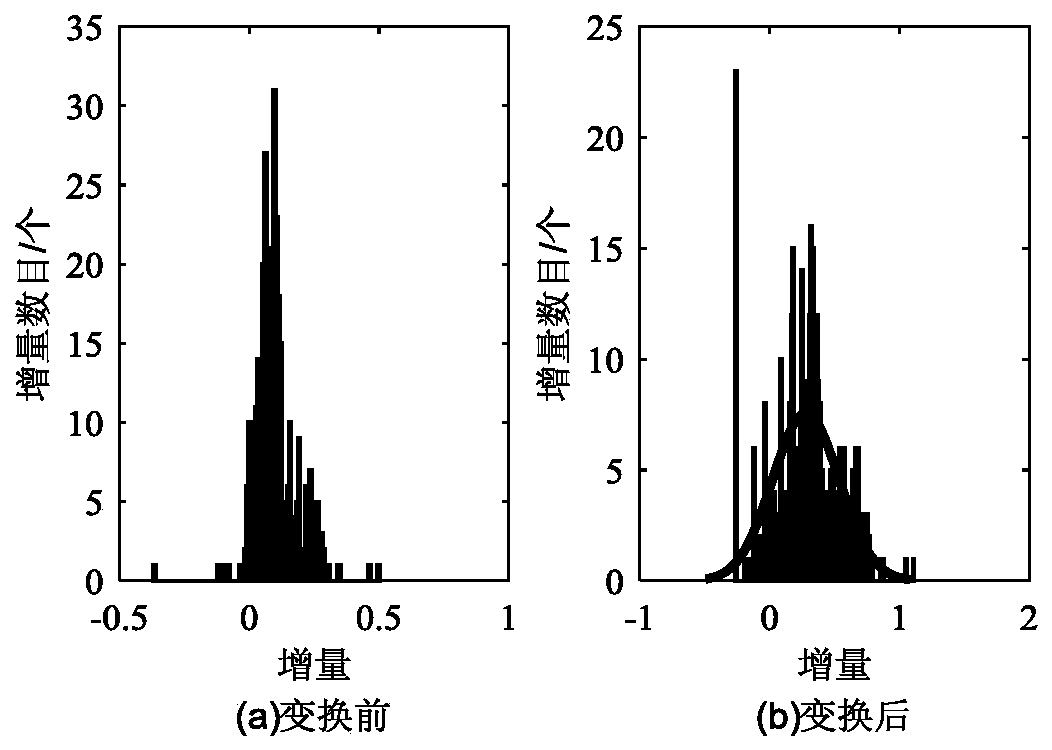

[0062] For the effective value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com