Method capable of quickly manufacturing LED colorful light cube

A technology of multi-color light and LED SMD light, which is applied in the direction of instruments, identification devices, static indicators, etc., can solve the problems of complex production of LED colorful light cube frames, difficulty in rapid mass production, and inability to ensure consistency in quality, and achieve the goal of manufacturing The process is simple and reliable, quick to build, and the effect of good mass production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the specification and drawings, elements having the same function and structure are denoted by the same reference numerals, and repeated description of these structural elements is omitted.

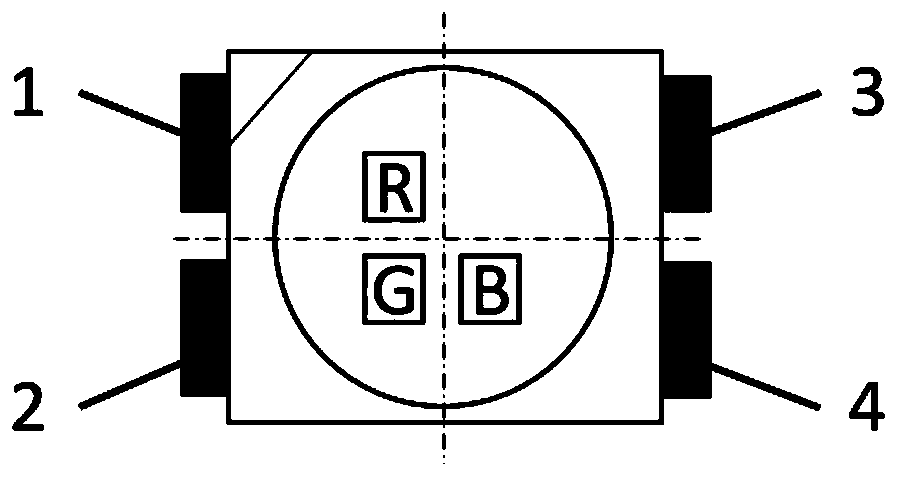

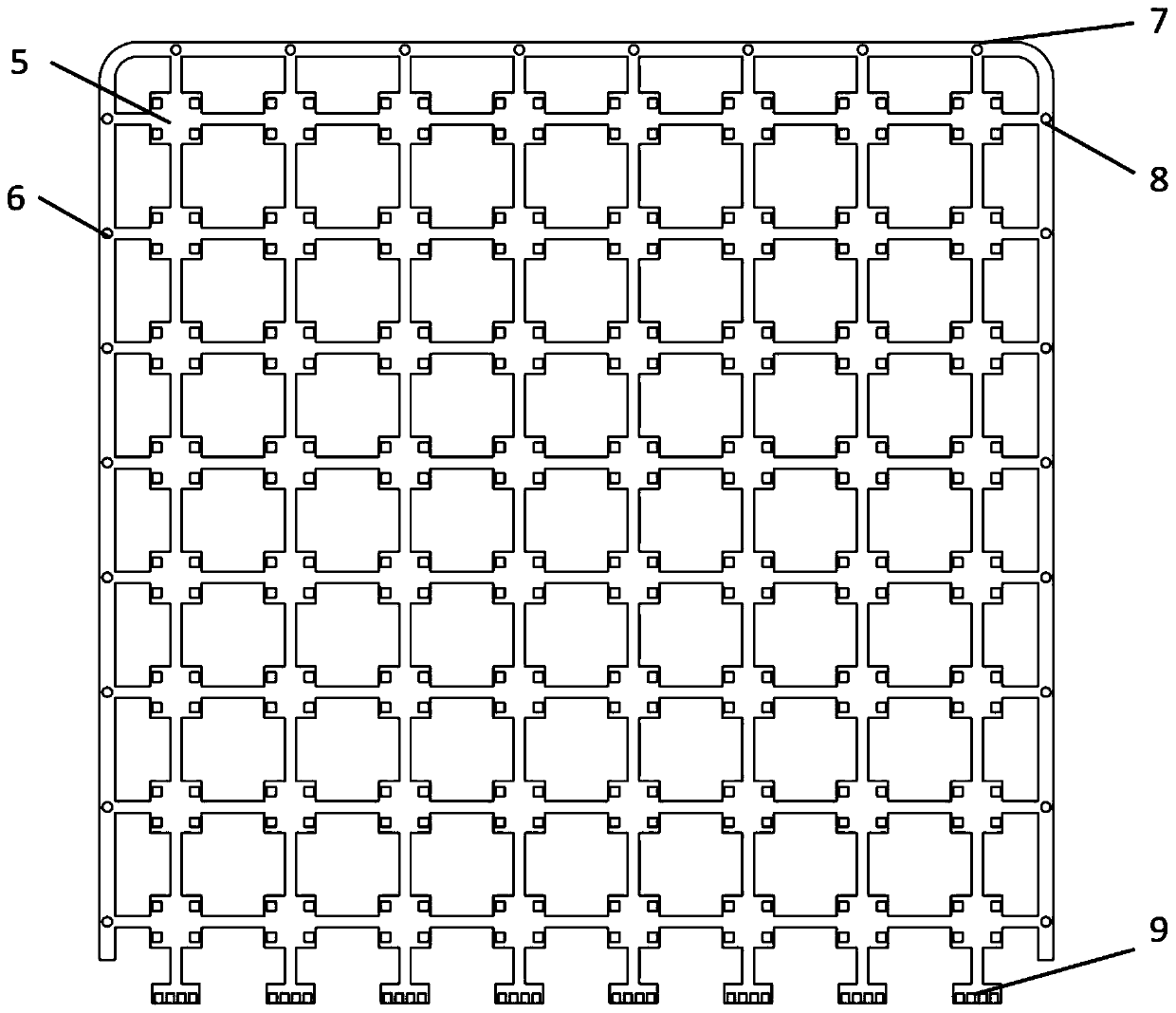

[0020] figure 1 Shown is a four-pin common anode RGB three-color LED patch light, figure 2 Shown is an 8×8 LED aluminum substrate 1 for light control. The welding position 5 of the LED patch lamp is reserved, and the four-pin control point welding position 9 is reserved at the bottom. The other places are hollowed out. This light board has four layers of circuits,

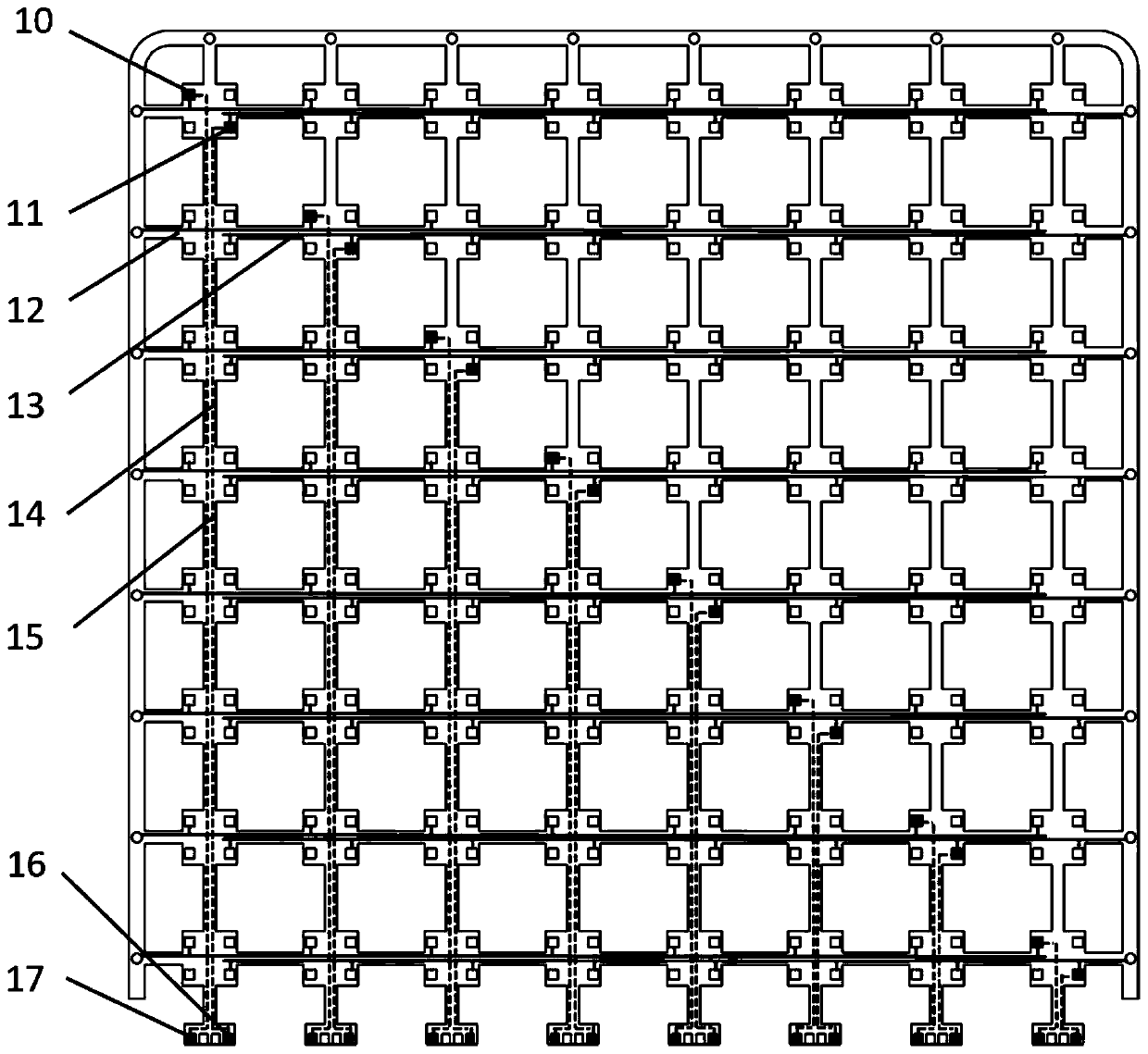

[0021] image 3 Shown are the circuit wiring diagrams of the first and second layers of the light board. Among them, the R pin row series circuit 12 and the B pin row series circuit 13 are located in the first layer of the circuit (solid line), and the R pins and B pins of each row of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap