Rotor skewed slot type generator

A generator and chute technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor heat dissipation performance of the rotor and low service life of the generator, so as to improve the performance and service life and reduce the weight of the rotor , Increase the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

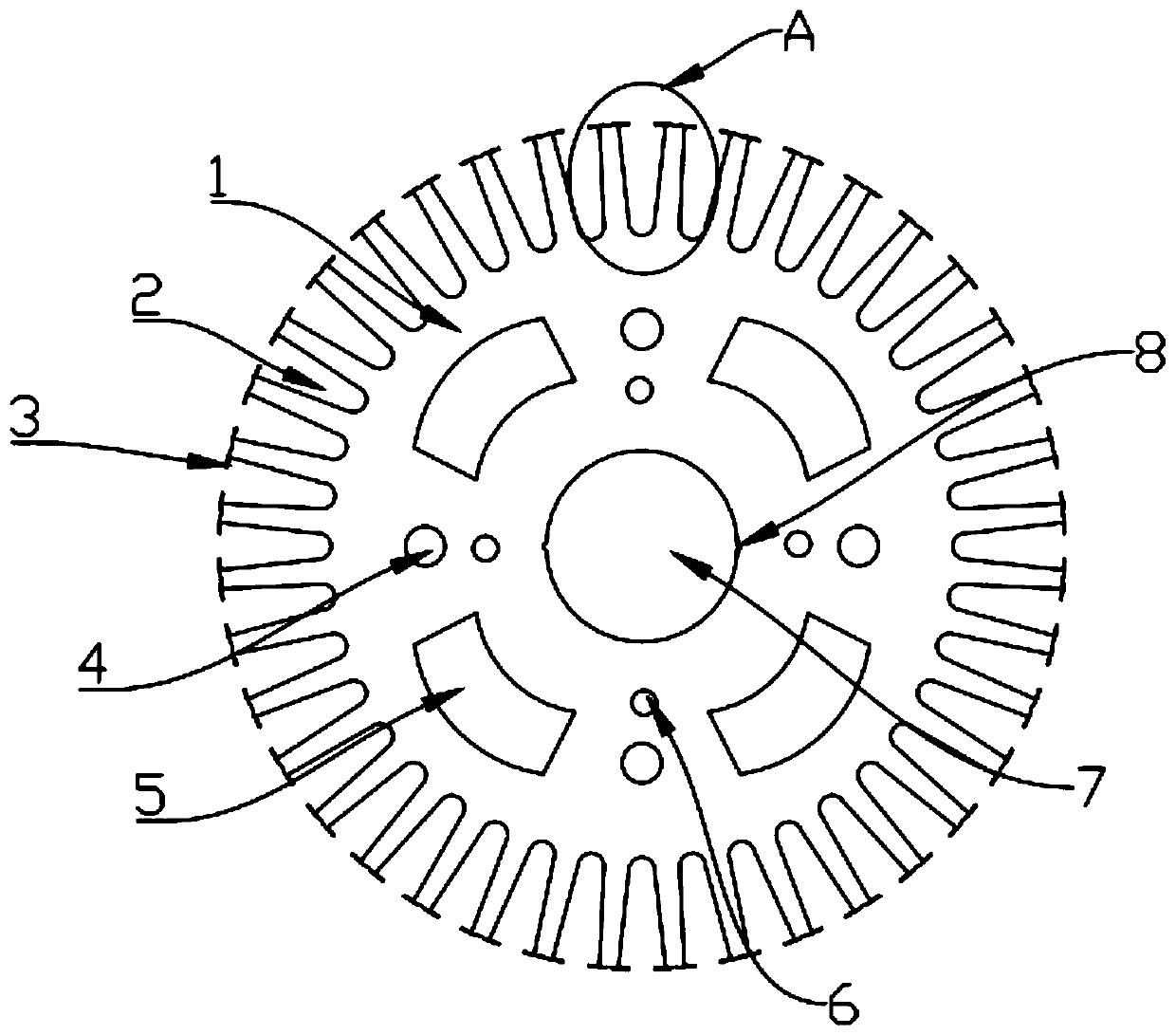

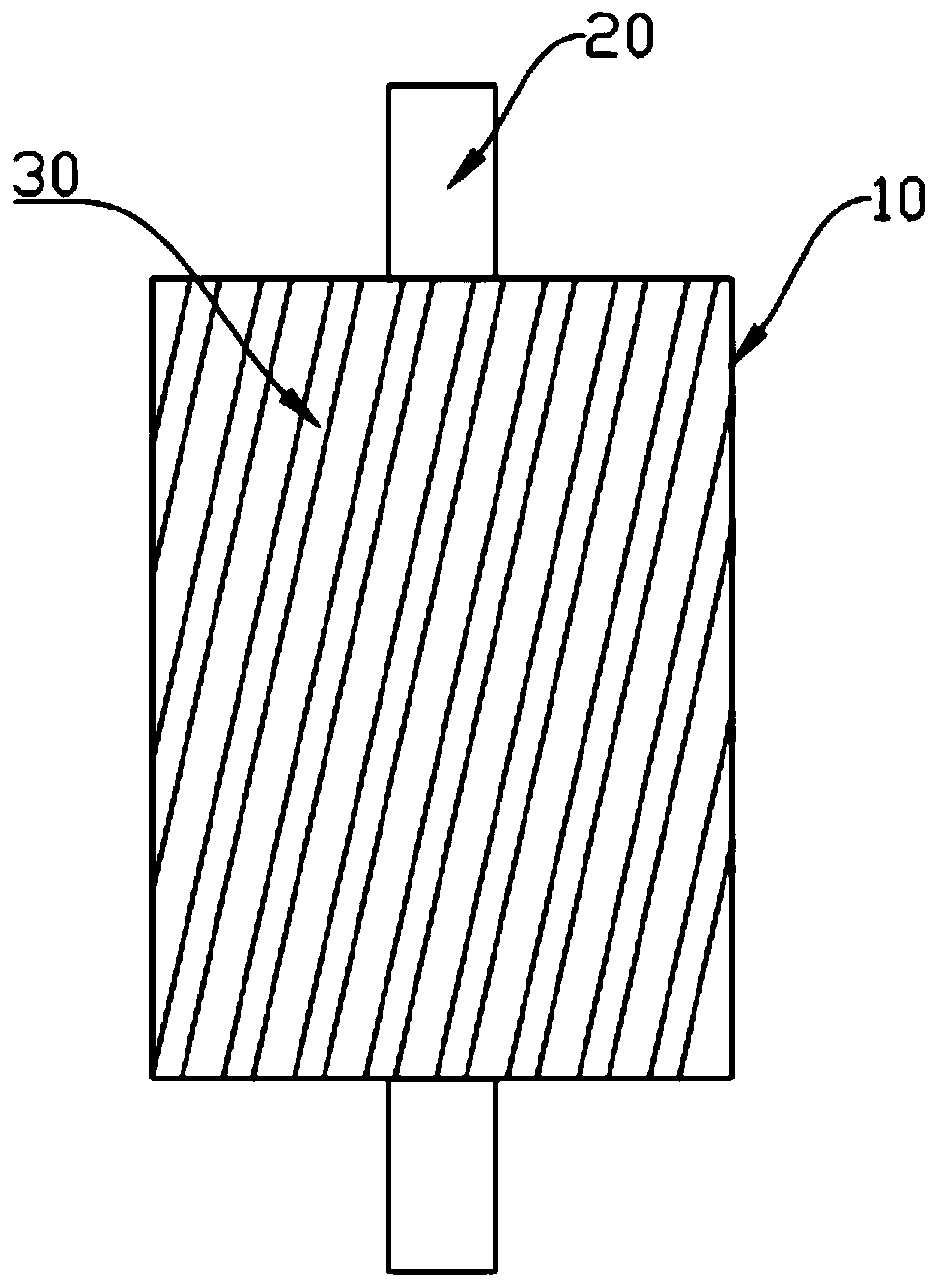

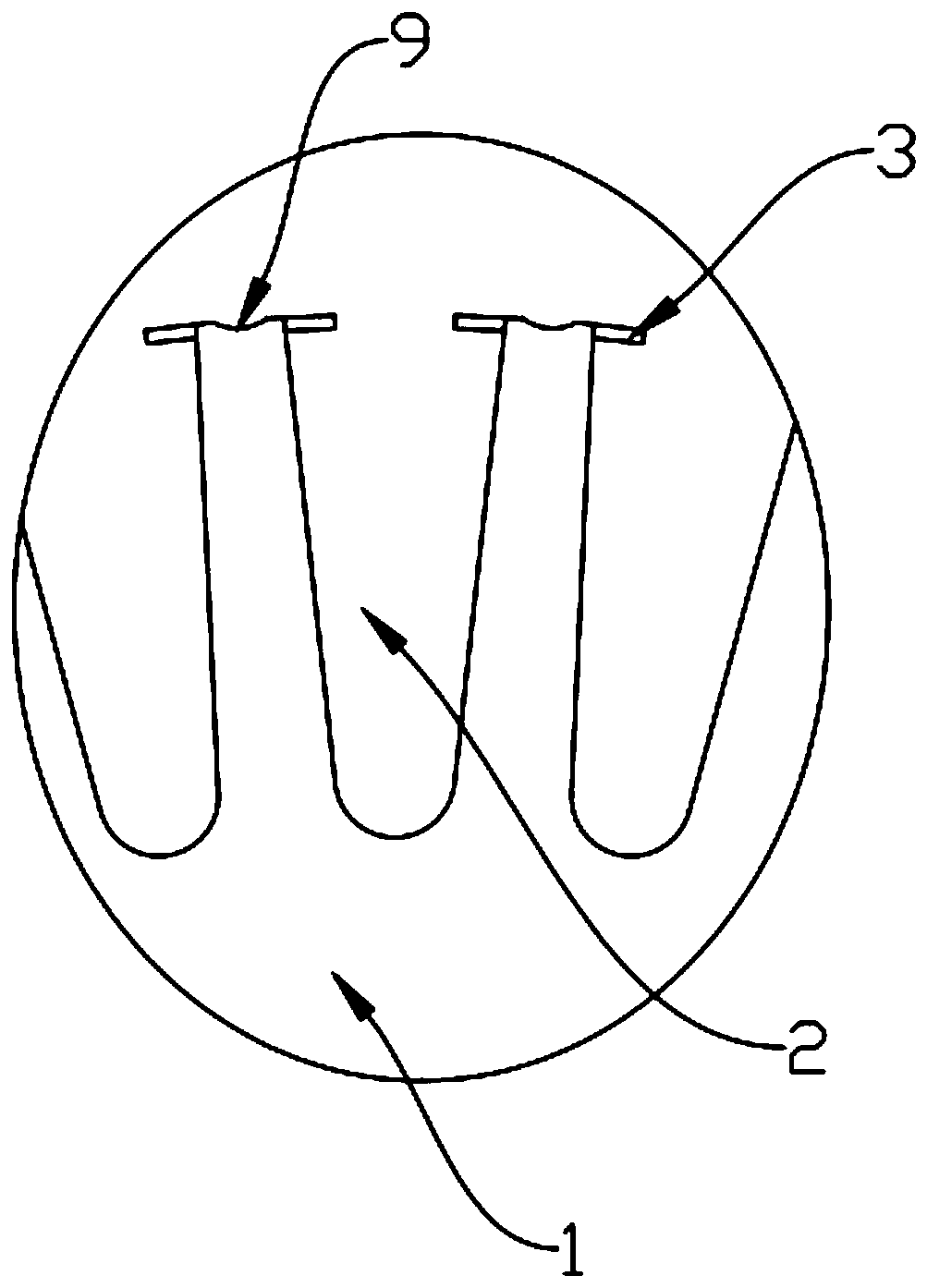

[0019] Such as Figure 1 to Figure 4 As shown, the technical solution of the present invention is a rotor skew generator, which includes a rotor body, and the rotor body includes a rotating shaft 20 and a rotor core 10 sleeved on the rotating shaft 20 . The rotor core 10 is formed by laminating multiple layers of rotor punches 1 with the same shape and size. A rotating shaft hole 7 is arranged in the center of the rotor punch 1 , wire slots 2 are evenly distributed on the outer circumference of the rotor punch 1 , and a number of cooling holes 5 are evenly distributed between the shaft hole 7 and the wire slot 2 . The wire slots 2 on two adjacent rotor punches 1 are smooth and excessive, and all the wire slots 2 on all the rotor punches 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com