Disassembling and assembling tool for cutter head of dicing cutter for producing resin

A technology of granulator and cutter head, which is applied in metal processing and other directions, can solve the problems of spending a lot of time repairing, spline contact surface damage, blade collision damage, etc., to shorten the time of disassembly and assembly, force balance, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

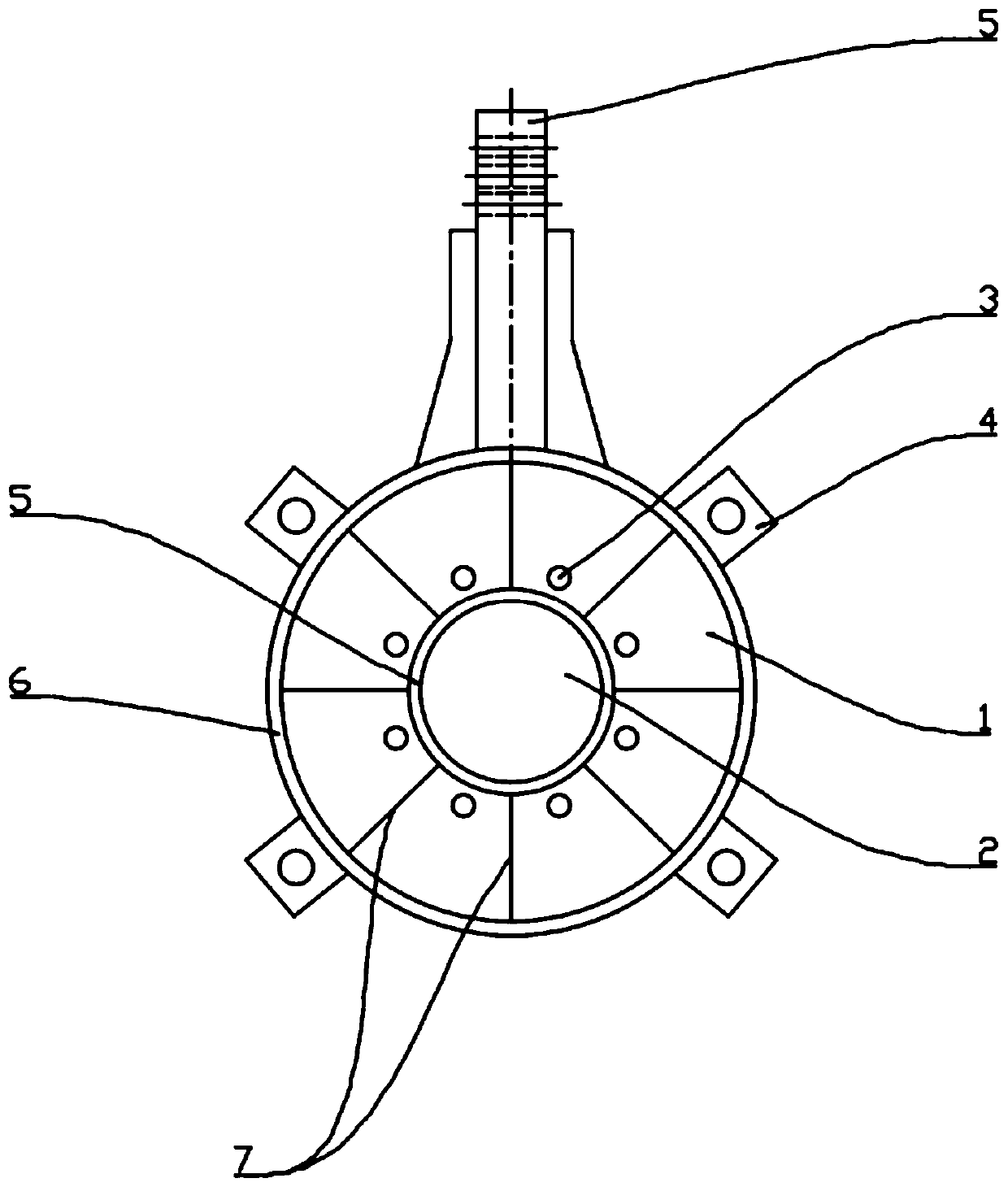

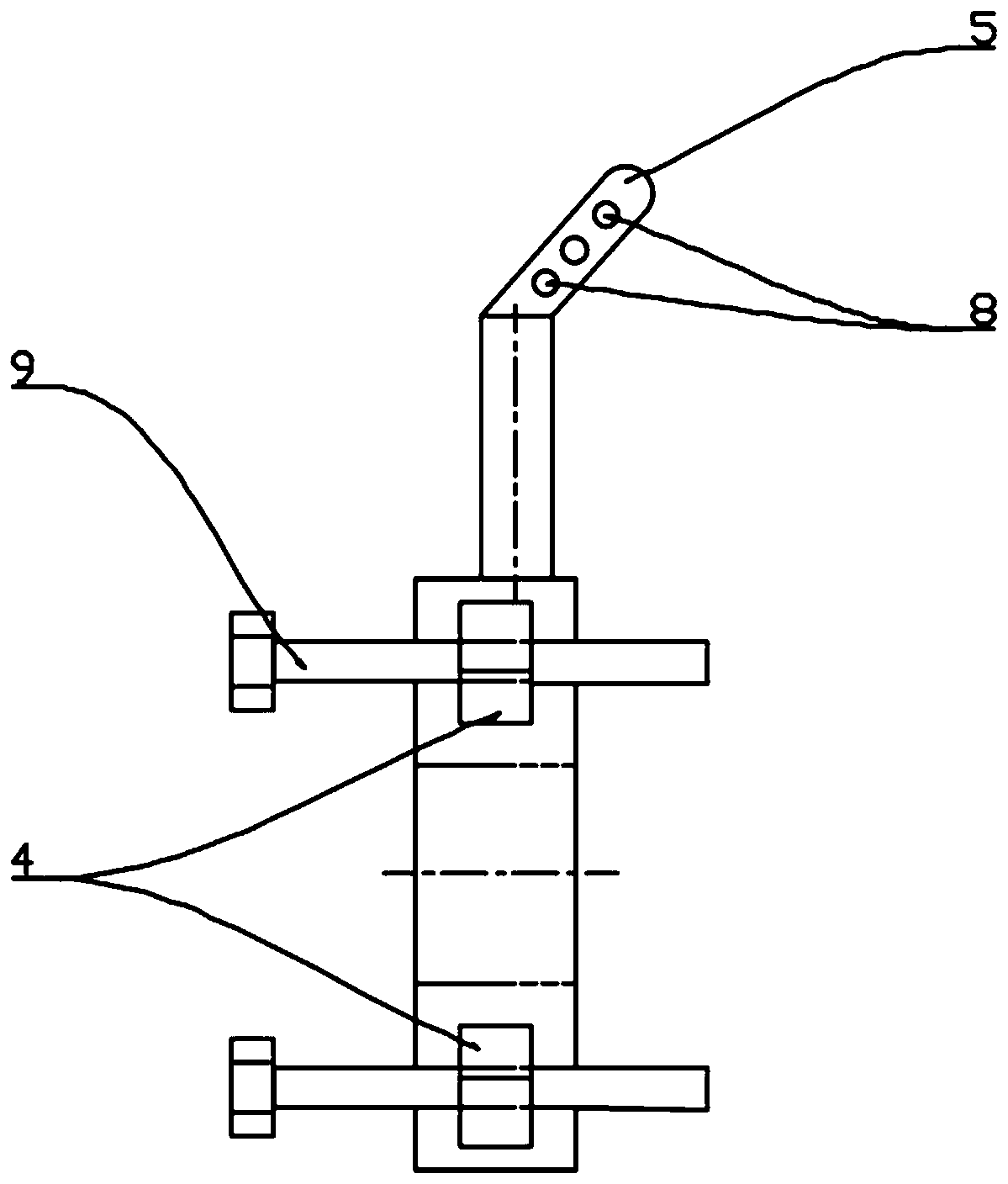

[0022] refer to figure 1 , combined with figure 2 , a disc 1 for disassembling and assembling the cutter head of the pelletizer for producing resin, including a disc 1 that is docked with the cutter disc of the pelletizer and can cover the entire cutter disc of the pelletizer. The center hole 2 of the connecting bolt between the cutter head of the pelletizer and the shaft, four positioning holes 3 that match the mounting holes on the cutter head of the pelletizer are arranged symmetrically around the center hole 2 on the disc 1, and the positioning holes 3 is a through hole, an installation portion is provided on the outer circumference of the disk 1, and a short pipe 4 with an internal thread is fixed on the installation portion. The short pipe 4 is set as four and arranged symmetrically around the center of the circle. The internal thread of the pipe 4 is connected with a top wire 9, one end of the top wire 9 is fixedly connected with a nut, and the other end of the top wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com