Preparation device and method for on-line dyeing color dot yarn of cellulose fiber cheese

A technology of cellulose fiber and cheese, which is applied in dyeing, textile material processing, textile material drum processing, etc., can solve the problems of complex process and high cost, and achieve the effect of high efficiency and green production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

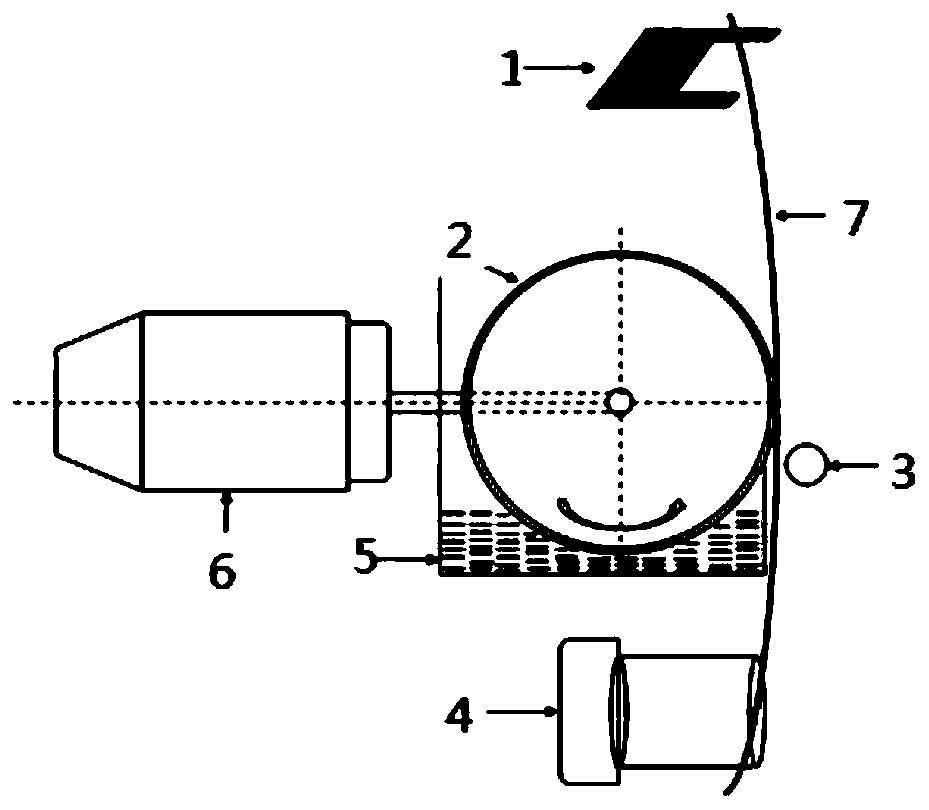

[0040] The device for preparing cellulose fiber cheese yarns for on-line dyeing of color dot yarns of the present invention includes dyeing components, which are composed of dyeing tank 5, dyeing runner 2, motor 6 and yarn pressing rod 3, and the dyeing component is located in the overfeeding device Between 4 and the yarn break automatic stop sensor 1, the motor 6 is connected to the dyeing runner 2 through a rotating shaft. The dyeing runner 2 is located in the dyeing tank 5. The yarn 7 passes through the overfeeding device 4 and is connected to the yarn break automatic stop sensor 1. The pressure rod 3 presses the yarn 7 on the dyeing wheel 2.

[0041] The diameter of the dyeing wheel 2 is 5 cm.

[0042] The dyed yarn adopts 25tex pure cotton yarn. The style of the dyeing wheel is a smooth circular cross section, and the diameter of the wheel is 5cm.

[0043] The method for preparing cellulose fiber cheese yarn dyed on-line color dot yarn of the present invention includes the foll...

Embodiment 2

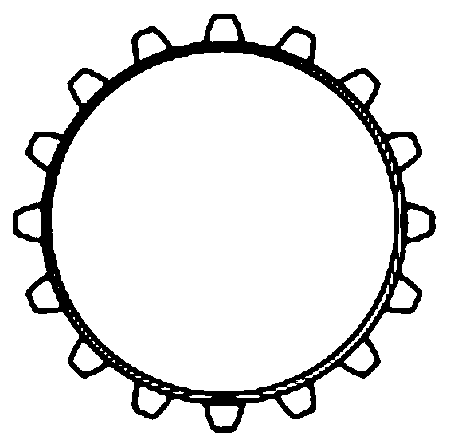

[0049] The cellulose fiber cheese in-line dyeing color dot yarn preparation device described in Example 2 is the same as that in Example 1, except that the dyeing wheel 2 has a tooth-shaped cross section, and the specific style is as attached figure 2 As shown, the diameter of the dyeing wheel 2 is 7 cm.

[0050] The dyed yarn adopts 14.5tex cotton / tencel (50% / 50%) blended yarn.

[0051] The method for preparing cellulose fiber cheese yarn dyed on-line color dot yarn of the present invention includes the following steps:

[0052] The preparation of the dye solution: The dye is selected as Sumitomo medium temperature dye blue-red R3BF (double reactive group dye, monochloros-triazine and vinylsulfone group), and the mass ratio of n-propanol, water and reactive dye is 50:45: 5.

[0053] The pretreatment of pure cotton cheese yarn: the cellulose fiber cheese yarn is pretreated by a cheese yarn dyeing machine. The amount of sodium carbonate and cationic fixing agent used in the pretreatme...

Embodiment 3

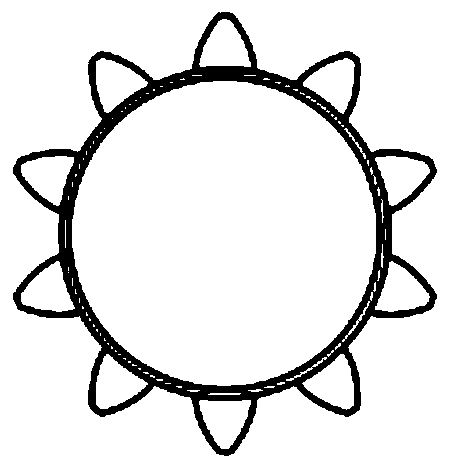

[0057] The cellulose fiber cheese yarn in-line dyeing color dot yarn preparation device described in Example 3 is the same as that in Example 1, except that the specific pattern of the zigzag section of the dyeing wheel 2 is as attached image 3 As shown, the diameter of the dyeing wheel 2 is 9 cm.

[0058] The dyed yarn uses 20tex flax fiber yarn.

[0059] The method for preparing cellulose fiber cheese yarn dyed on-line color dot yarn of the present invention includes the following steps:

[0060] The preparation of the dye solution: The dyes are respectively selected as Sumitomo medium temperature dyes blue B-4R (monofluoros-triazine reactive dyes) and red R3BF (double reactive dyes, monochloros-triazine and vinylsulfone based), alcohol solvents are selected For the mixed solution of ethanol and glycerol (the mass ratio of the two is 3:1), the mass ratio of the alcohol solvent, water, and reactive dye is 60:36:4.

[0061] Pretreatment of pure cotton cheese yarn: pretreatment of ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com