Process for continuous cationic modification of fabric and dyeing with reactive dyes

A cationic modifier and reactive dye technology, applied in the field of fabric modification and dyeing process, fabric modification and dyeing continuous treatment process, can solve the problems of poor directness, uniform yellowing of modified cotton fabric, uncontrollable color and light, etc. , to achieve the effect of improving the utilization rate of dyes, improving the dyeing fastness and shortening the washing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

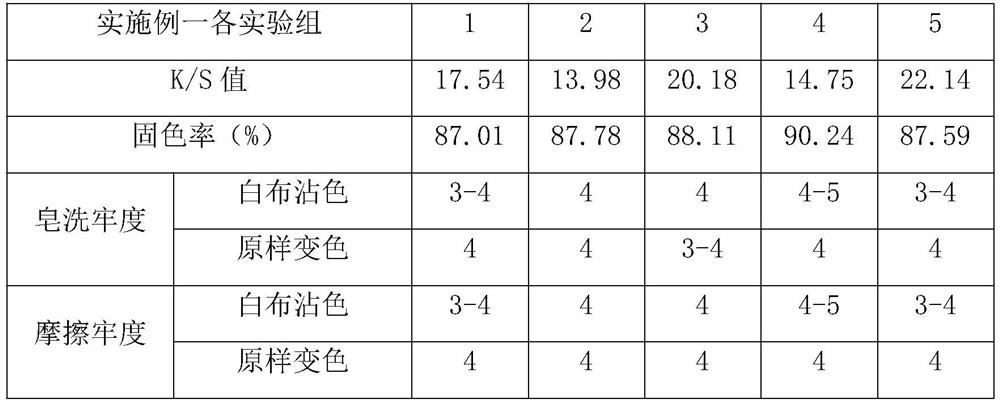

Embodiment 1

[0020] Raw material used in the present embodiment, cationic modifier is commercially available 3-chloro-2-hydroxypropyltrimethyl ammonium chloride product, and reactive dyestuff is the commercially available product of DyStar (Shanghai) Trading Co., Ltd., other All raw materials used are commercially available products. In the present embodiment, a kind of fabric continuous cationic modification and the method for reactive dye dyeing, its steps are as follows:

[0021] (1) padding cationic modification liquid process: prepare the modification liquid containing cationic modifier and caustic soda, dip and roll twice on the padding car at room temperature, and the excess rate is controlled at 65±2%; In the neutral liquid process, the cationic modifier adopted adopts 3-chloro-2-hydroxypropyltrimethylammonium chloride; in the padding cationic modified liquid process, the above-mentioned cationic modifier The mass concentration in the solution is 50-150g / L, and the molar ratio of ...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, especially in that:

[0037] In this embodiment, the process of padding cationic modified liquid and the process of microwave irradiation are carried out twice respectively, and the fabric is firstly subjected to the process of padding cationic modified liquid for the first time, and then microwave irradiation is carried out in a microwave irradiation device to make the fabric Modification; the fabric is subjected to padding cationic modification solution process again, and then microwave irradiation is repeated in the microwave irradiation device to modify the fabric. The cationic modification and reactive dyeing of cotton fabrics by using the device of this embodiment can realize continuous dyeing without salt, reduce the amount of printing and dyeing sewage treatment, and reduce production costs; Under the dye concentration, similar or higher surface color yield and dye fixation rate can be obtained, the color is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com