Power strip convenient to use and higher in safety performance

A safe and convenient technology, applied in the direction of circuits, electrical components, parts of connecting devices, etc., can solve the problems of reduced elasticity of the gray plate, reduced dust blocking effect, and cumbersome power consumption process, so as to reduce resistance and reduce Friction, realize the effect of power on and off control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

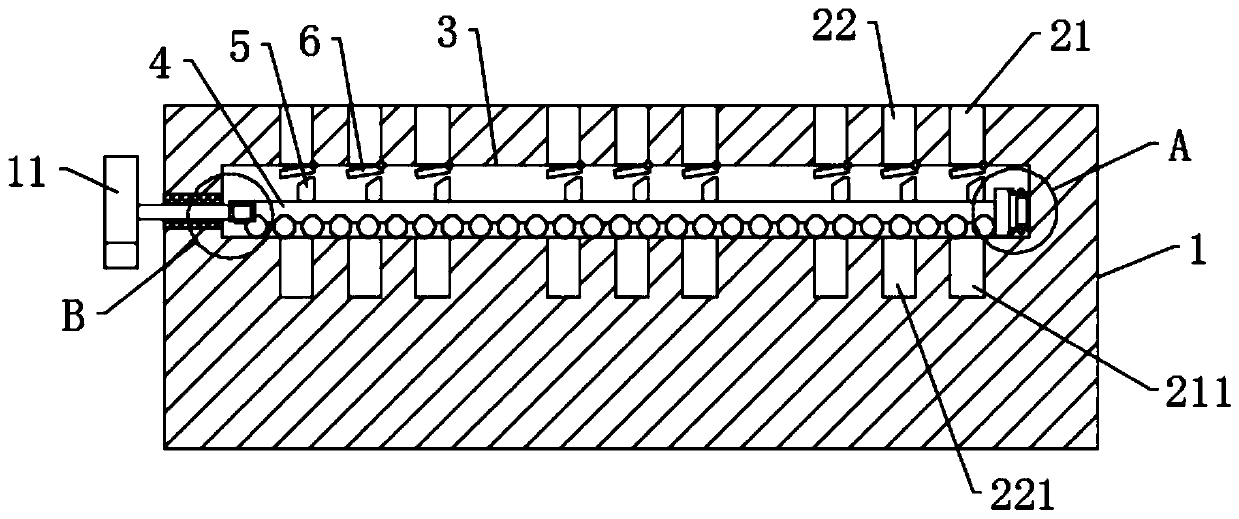

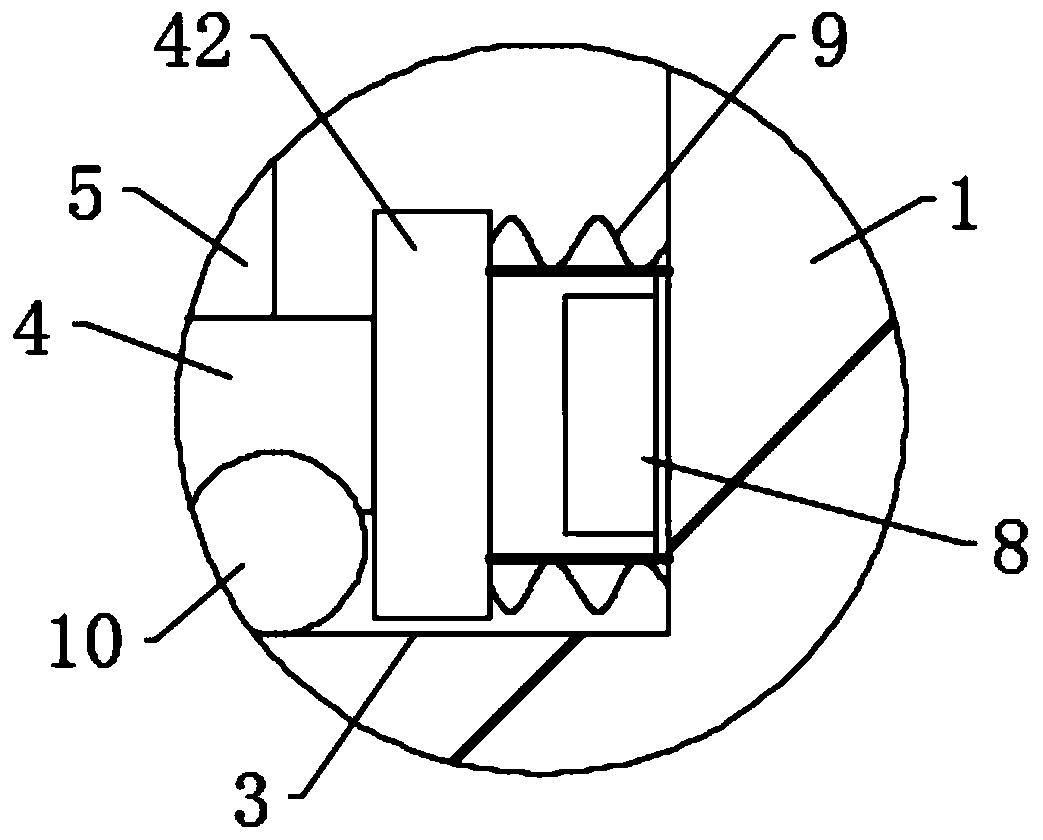

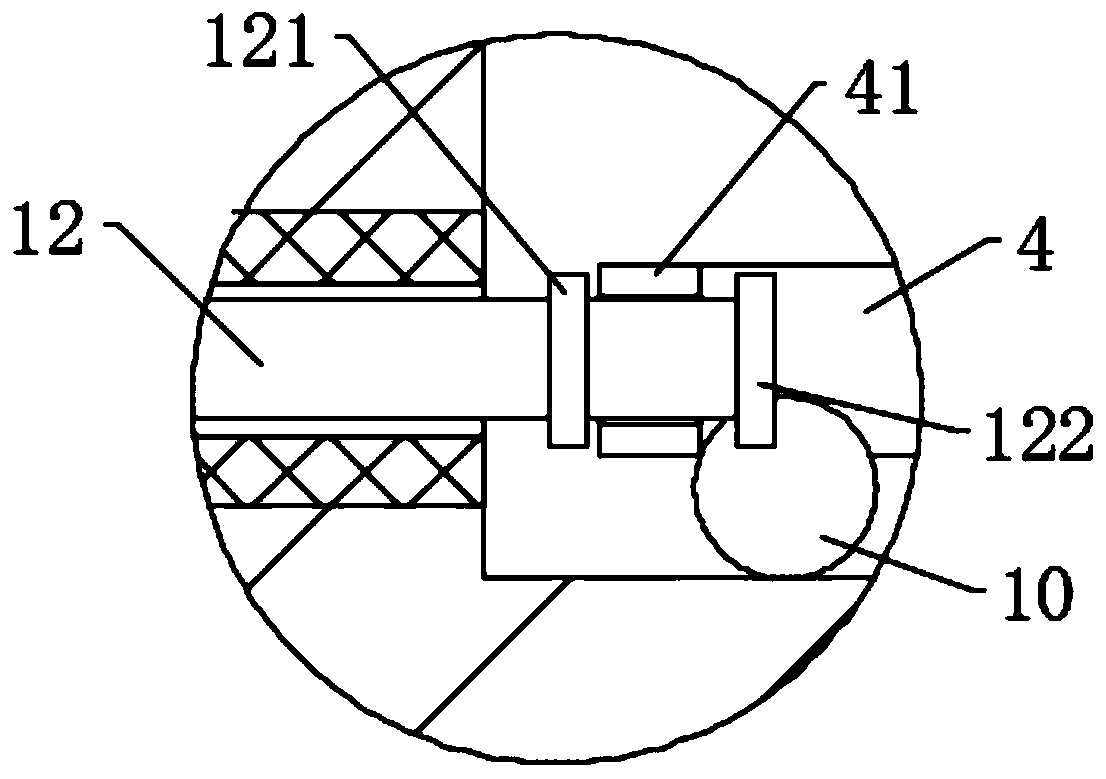

[0042] see figure 1 , an electrified plug-in strip that is convenient to use and has higher safety performance, including a board body 1, on which a plurality of socket groups, an inner cavity 3, and a power slot are drilled in sequence from top to bottom, and the socket group includes three sockets The hole 22 and the double jacks 21 on both sides of the three jacks 22, the energized slots include three slots 221 and the double slots 211 on both sides of the three slots 221, the lower ends of the double jacks 21 and the three jacks 22 are connected with a sealing plate 6. A pair of movable pieces 4 are slidably connected to the inner side of the inner chamber 3, and a plurality of extrusion strips 5 corresponding to the sealing plate 6 are fixedly connected between the pair of movable pieces 4.

[0043] The sealing plate 6 is rotated to the side close to the contact switch 8, and the extruding strip 5 is located between the sealing plate 6 and the contact switch 8. The end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com