Smashing device for traditional Chinese medicine machining

A crushing device and technology of traditional Chinese medicinal materials, applied in grain processing, etc., can solve the problems of reduced crushing efficiency, time-consuming and laborious, and increased costs, and achieve the effect of improving the crushing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

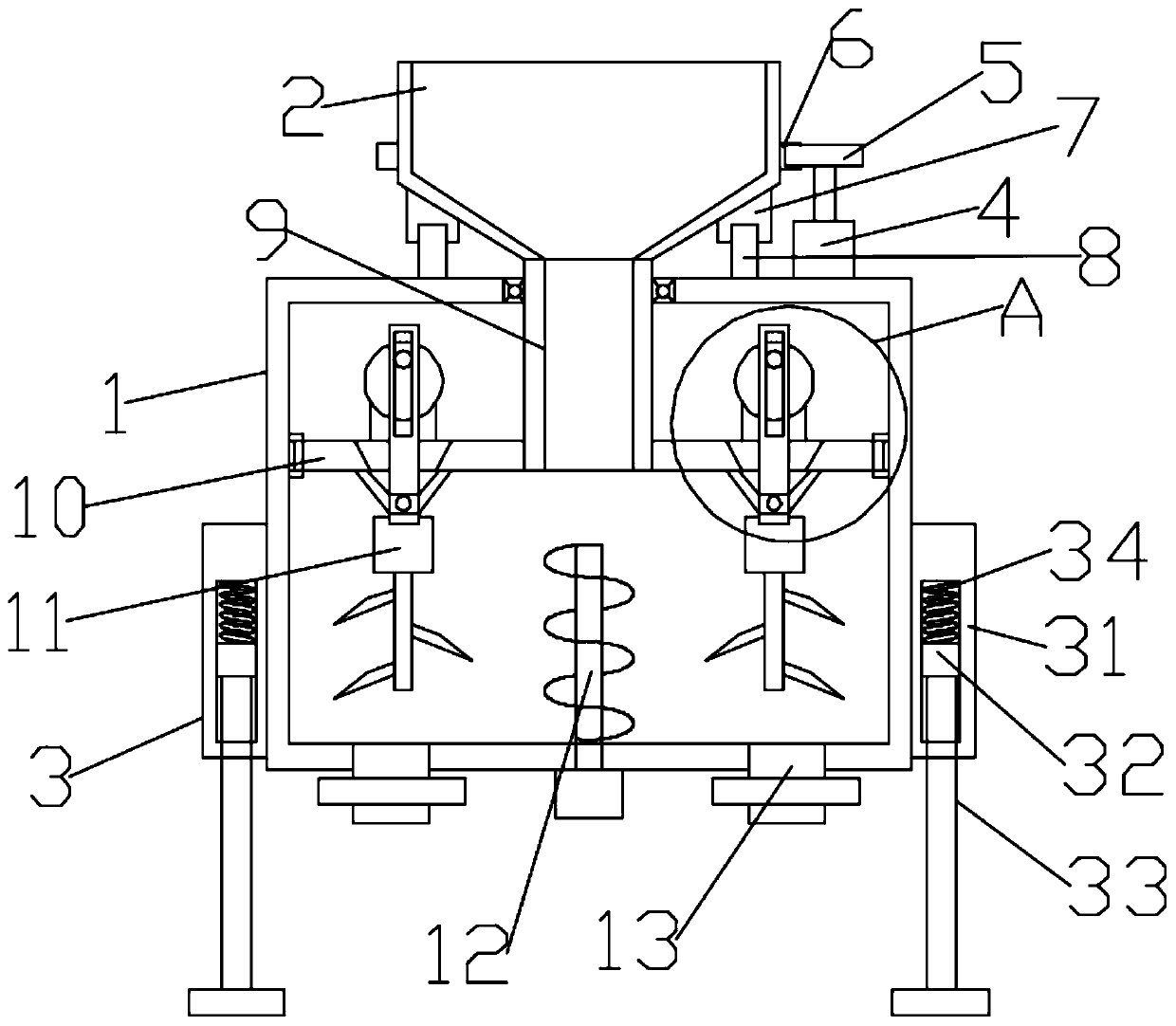

[0027] Such as figure 1 As shown, in the embodiment provided by the present invention, a crushing device for processing Chinese herbal medicines includes a crushing box 1 and a feeding assembly arranged on the top of the crushing box 1, and the crushing box 1 is also rotatably equipped with The rotating disk 10 linked with the feeding assembly; the first drive motor 4 for driving the feeding assembly and the rotating disk 10 to rotate synchronously is also installed on the top plate of the crushing box 1; the bottom surface of the rotating disk 10 is also symmetrically arranged There are two crushing assemblies 11, and the upper surface of the rotating disk 10 is provided with two swinging assemblies, and the two swinging assemblies respectively drive the two crushing assemblies 11 to swing, so that the rotating disk 10 is driven by the first drive motor 4 During the rotation process, the Chinese herbal medicines in the lower inner cavity of the crushing box 1 can be fully cru...

Embodiment 2

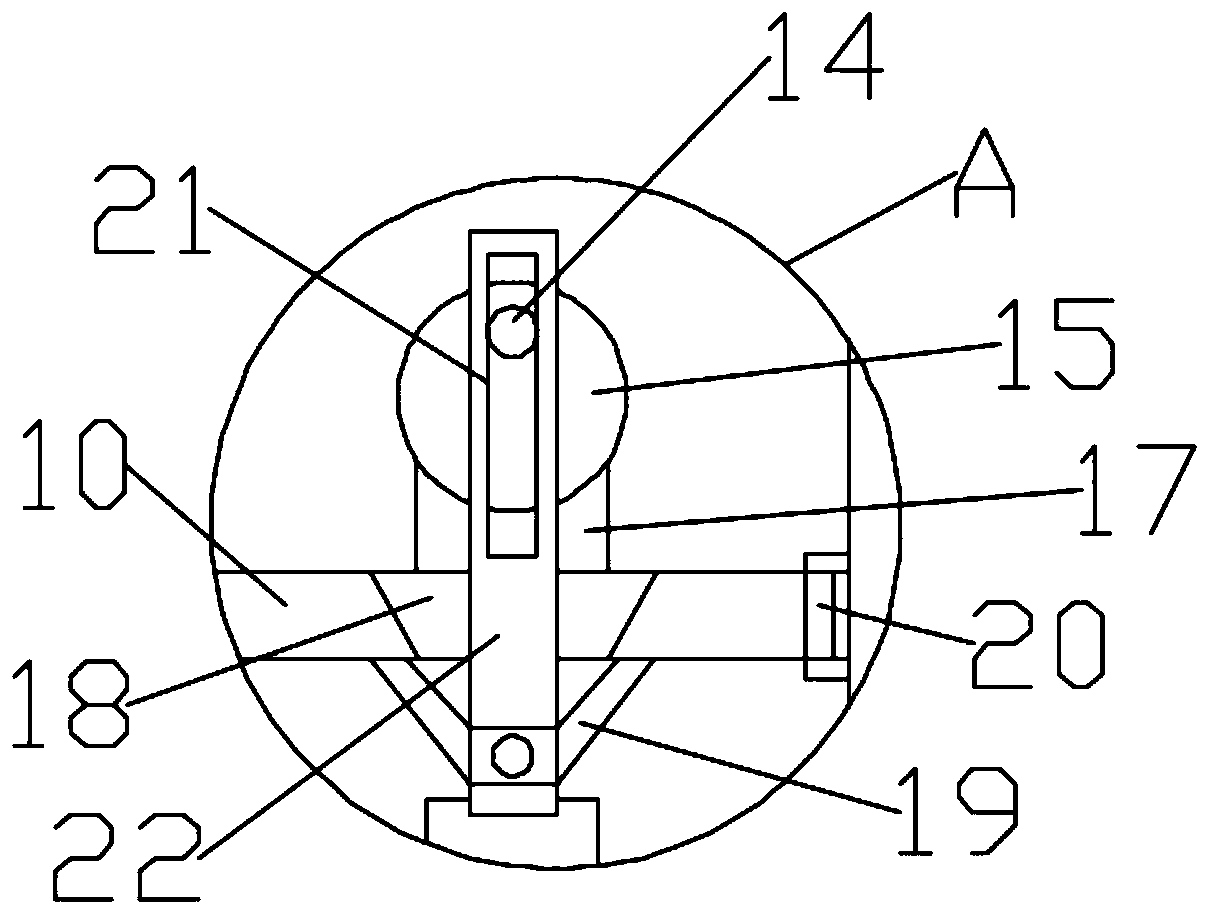

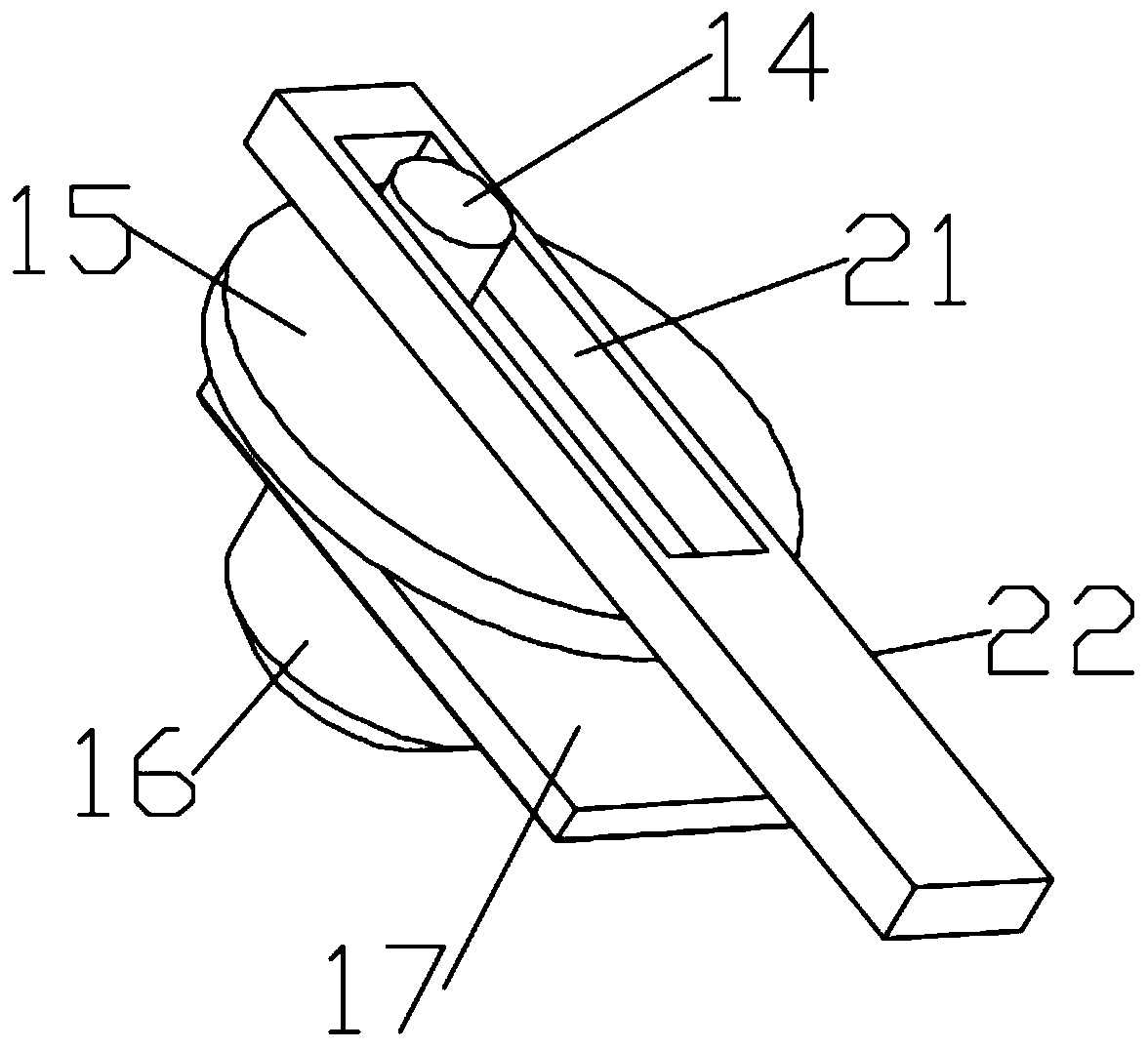

[0035] Such as Figure 1-3As shown, the difference from Embodiment 1 is that in the embodiment of the present invention, the swing assembly includes a support plate 17 fixedly installed on the upper surface of the rotating disk 10, and the rotating frame on the supporting plate 17 is provided with a rotating disk 15, so The support plate 17 is also fixedly installed with a second drive motor 16 for driving the rotation of the rotating disk 15; the end surface of the rotating disk 15 is fixedly equipped with a guide post 14;

[0036] Further, the oscillating assembly also includes a oscillating plate 22, the upper part of the oscillating plate 22 is slidably sleeved on the guide post 14 through the bar-shaped through hole 21 opened thereon; Channel 18, the lower surface of the rotating disk 10 is also fixedly installed with the support rod 19 corresponding to the channel 18, the lower part of the swing plate 22 is rotatably connected to the support rod 19 in a hinged manner, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com