Early warning method of head deviation of rough-rolled intermediate billet in steckel mill line

A furnace coil rolling and head technology is applied in the field of early warning of rough rolling intermediate billet head deviation in a furnace coil rolling line, which can solve the problems of rough rolling intermediate billet deviation, scrap steel, and the inaccessibility of the intermediate billet head, etc. Achieve the effect of preventing steel scrap in furnace coil mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0013] The invention provides an early warning method for deviation of the head of a rough rolling intermediate slab in a coil rolling line.

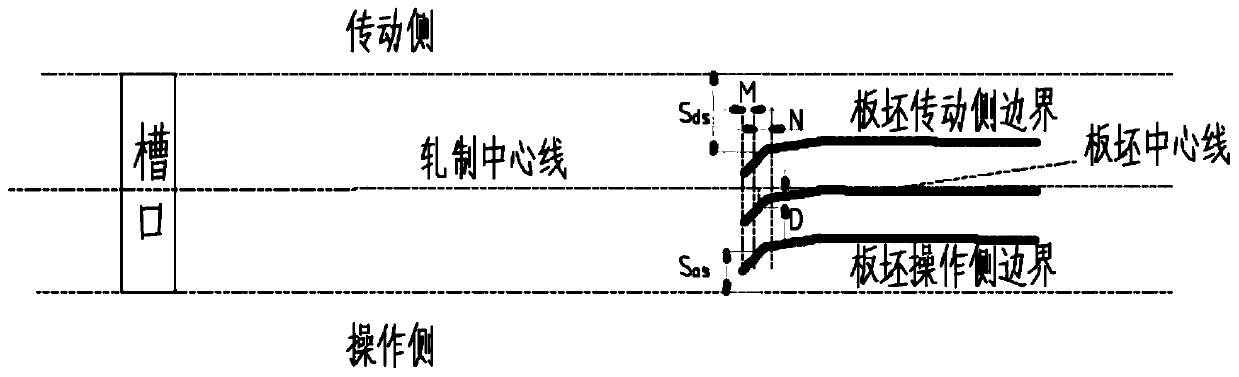

[0014] This method calculates the center line of the intermediate billet within Nmm after the head of the intermediate billet is removed from the head of the flying shear and the shear length Mmm is set according to the billet center line deviation and width deviation measured by the rough rolling exit width measuring instrument at the last pass. Mean D of Deviation D avg And the distance S between the operating side and the driving side and the corresponding side of the coiling furnace notch of the steckel mill os and S ds mean S osavg and S dsavg ; when D avg >D permit When the HMI ejects the center line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com