Special stainless steel wire machining equipment stable splicing installing frame

A technology for stainless steel wire and processing equipment, which is applied to the field of stable splicing and mounting brackets for stainless steel wire processing equipment, can solve the problems of large workload, low efficiency and high difficulty, and achieve the effects of convenient operation, high efficiency and small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

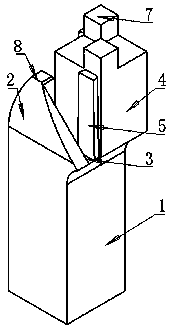

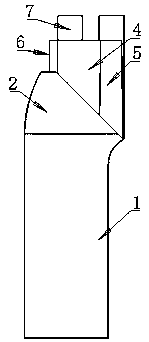

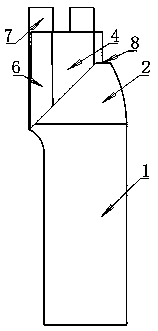

[0019] like Figure 1 to Figure 7 As shown, a special stable splicing installation frame for stainless steel wire processing equipment can be installed in conjunction with multiple fixed positions of the wire drawing equipment during use. It can ensure the overall connection fastness of the assembly, and the overall locking can be completed without using other auxiliary accessories during assembly. The number of parts used in the installation is less, and the operation during assembly is more convenient, ensuring the overall in- The efficiency of installation is higher. When this part is assembled, multiple positions at the upper end are simultaneously spliced, which can make the connection firmer at the connection position and ensure the safety and stability of the wire drawing equipment during use. More reliable , It is also more convenient to disassemble and operate during the maintenance of the equipment in the later stage. It includes a main body installation stable supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com