Fuel injection pump gear drawing tool

A fuel injection pump and gear technology, applied in the field of fuel injection pump gear drawing tooling, can solve problems such as damage to the fuel injection pump wheel, affecting power transmission, slow work efficiency, etc., to achieve the effect of easy operation, reducing overall weight, and avoiding damage or damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

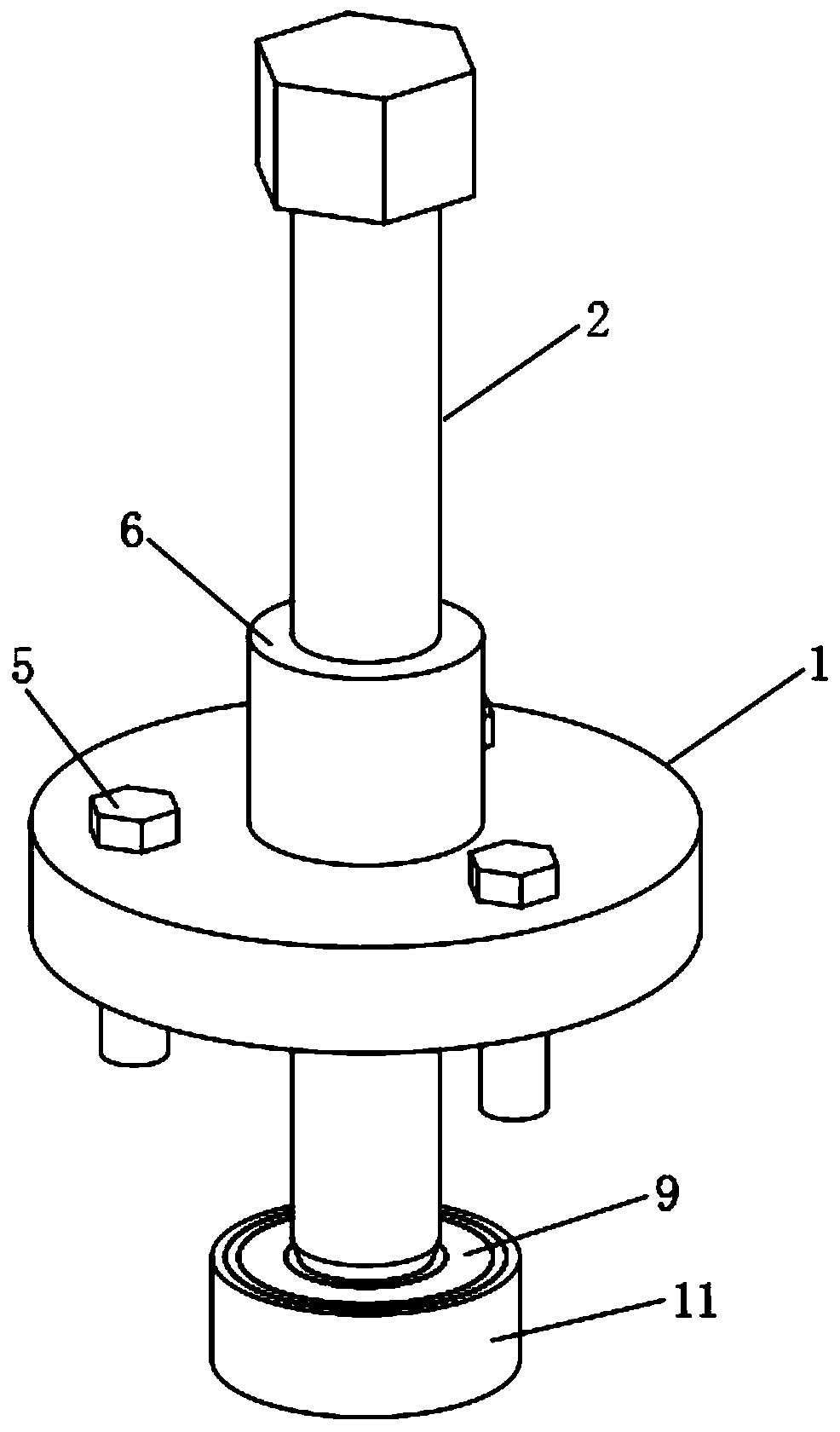

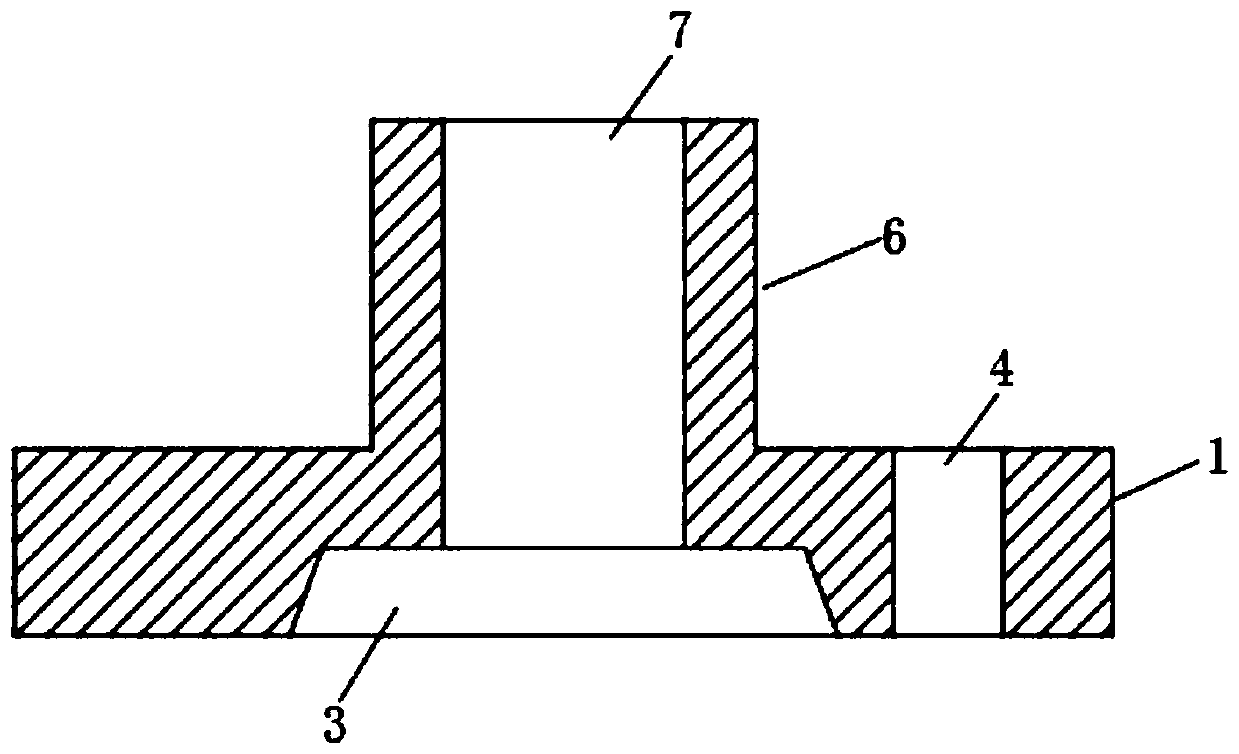

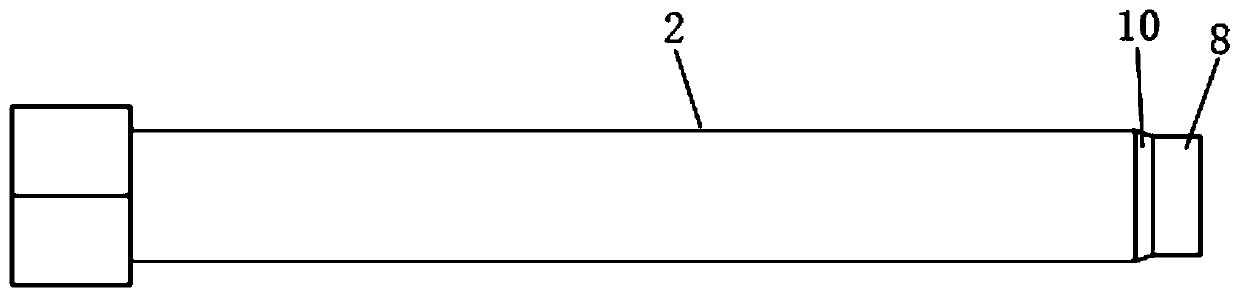

[0022] refer to Figure 1-Figure 2 , a fuel injection pump gear drawing tool of the present invention includes a base 1 and a drawing bolt 2 . The bottom of the base 1 is provided with an insertion groove 3 for inserting the middle protrusion of the fuel injection pump wheel 13, so that the end surface of the base 1 fits with the end surface of the fuel injection pump wheel 13 to protect the middle protrusion of the fuel injection pump wheel 13. The base 1 is provided with a plurality of mounting holes 4 corresponding to the threaded holes of the fuel injection pump wheel 13 , and positioning bolts 5 are installed in the mounting holes 4 . The base 1 can be fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com