Double-gas-chamber air cylinder for hot runner system

A dual-air chamber and hot runner technology, applied in the field of hot runner cylinders, can solve problems such as affecting the service life of the cylinder and enhancing the output force of the cylinder, achieving the effect of reducing the number of parts, enhancing the output force, and avoiding the use of booster pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

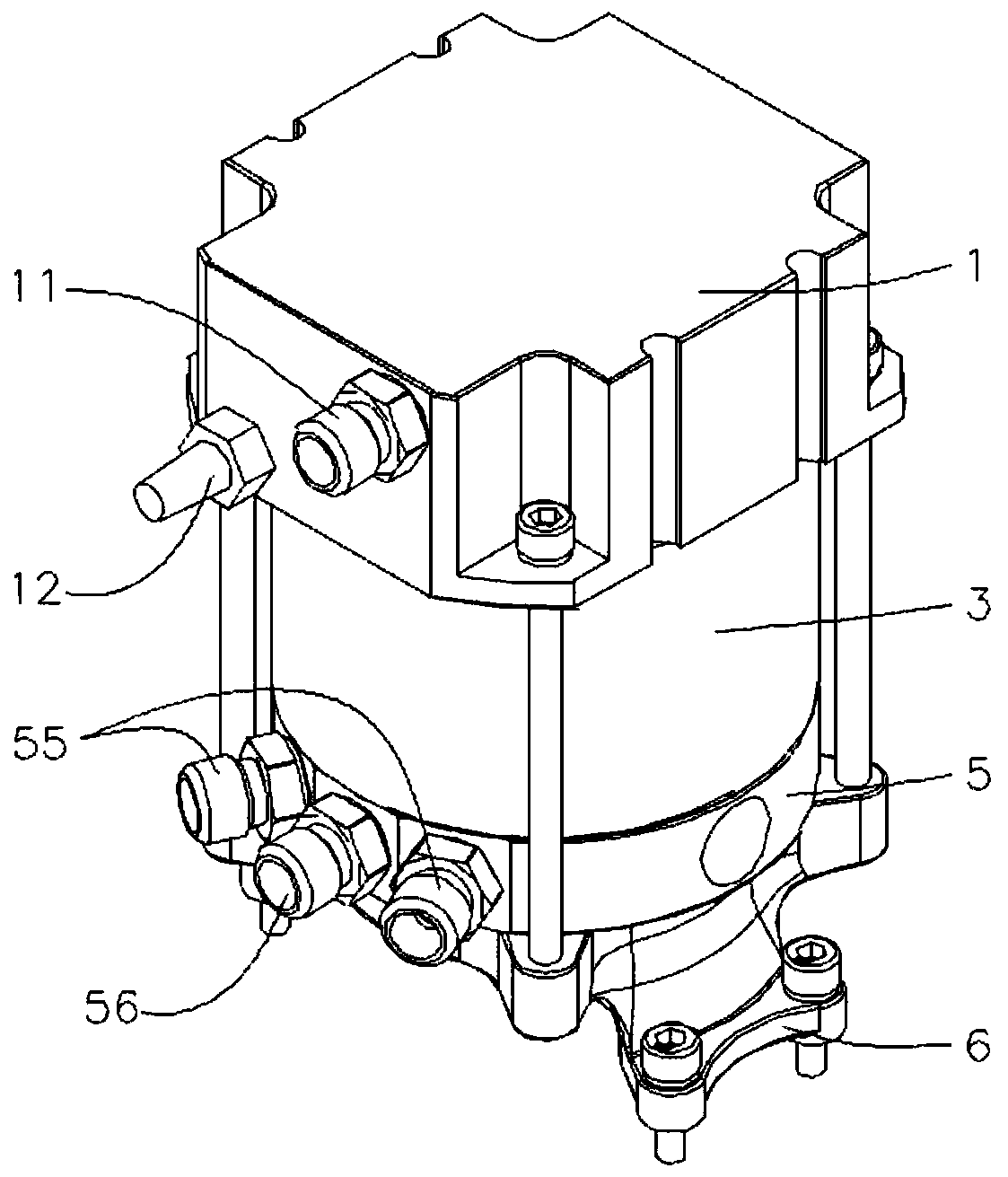

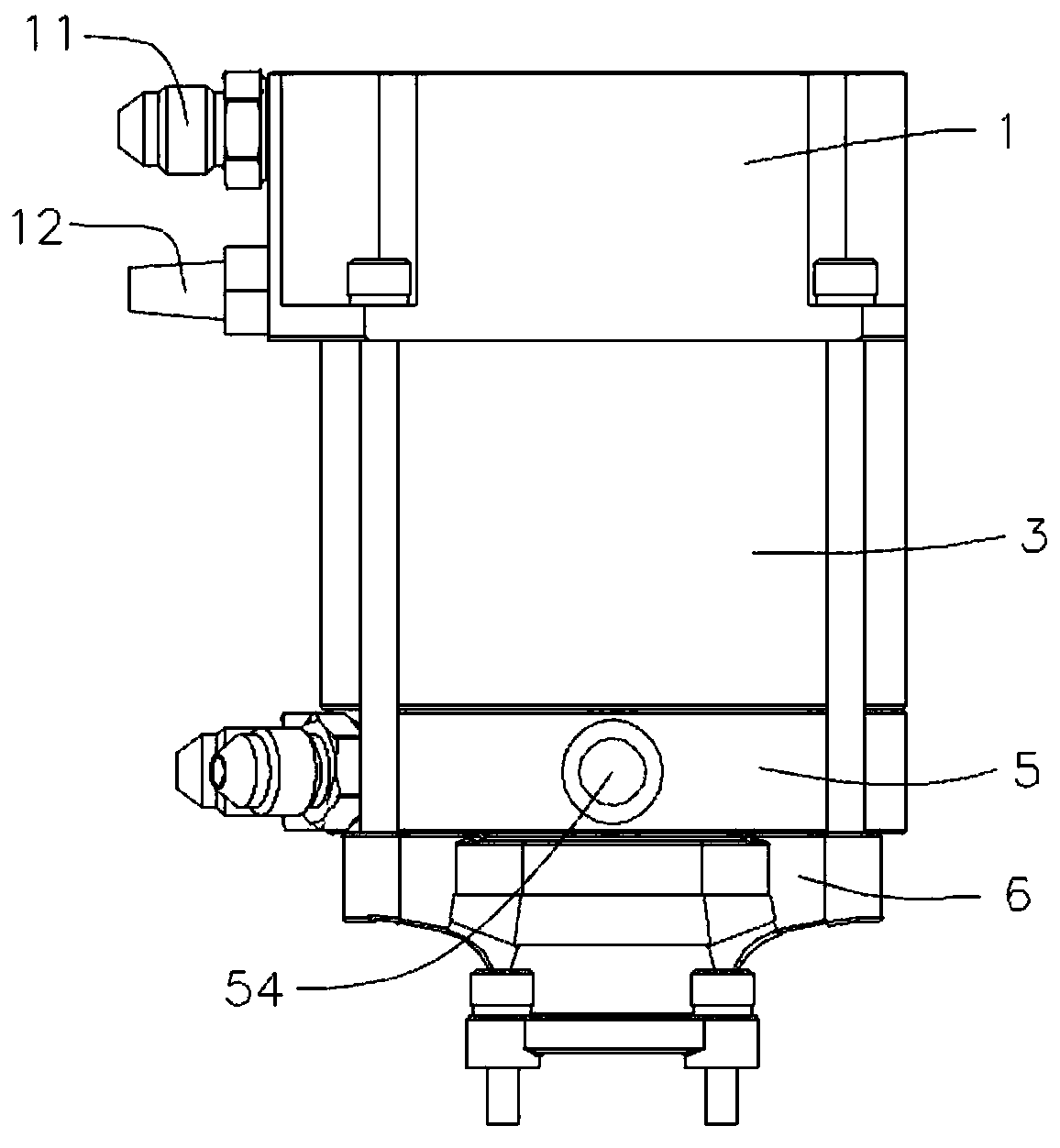

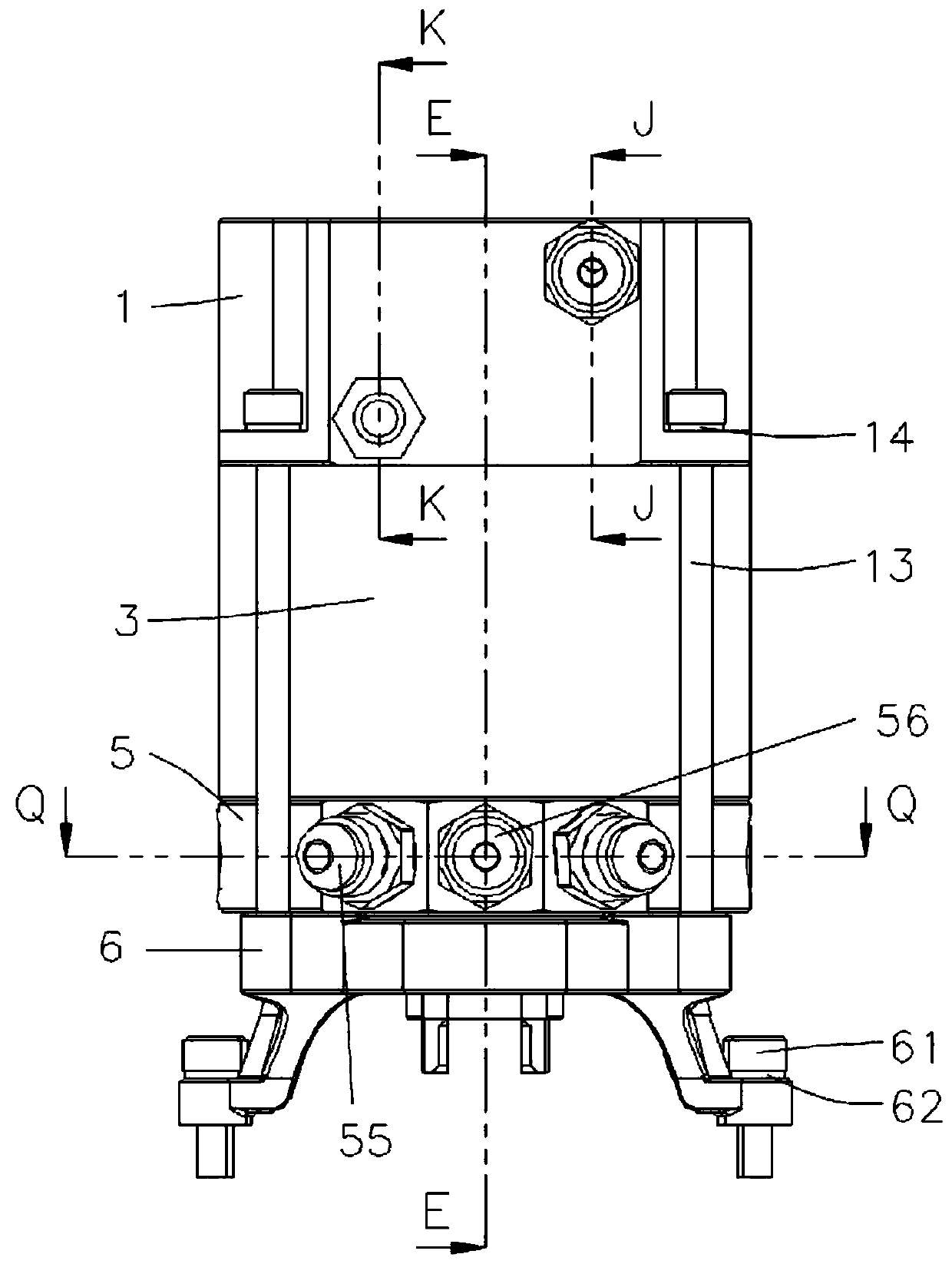

[0044] A double-chamber cylinder used in a hot runner system. The double-chamber cylinder is acted on by pressurized gas. It is characterized in that the double-chamber cylinder includes: an upper cylinder body 1 , a lower cylinder body 3 , a cooling bottom plate 5 and a support seat 6 . Among them, the upper piston 2 acts on the lower piston 4, and the two ends of the first gas channel are respectively connected to the upper piston ejection chamber UC1 and the lower piston ejection chamber UC2; and the pressure gas acts simultaneously through the first gas channel On upper piston 2 and lower piston 4.

[0045] The upper cylinder body 1 has an air chamber with a lower opening. The upper cylinder body 1 is provided with a first air circuit joint 11 and a second air circuit joint 12 , and the upper cylinder body 1 is also provided with an upper piston 2 .

[0046] The upper piston 2, the upper piston 2 is set in the air chamber of the upper rod body, and the upper cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com