Method for removing anodic oxide film on surface of seven-series aluminum alloy and film removing agent

A technology for anodic oxide film and aluminum alloy surface, which is applied in the field of anodic oxide film release treatment method and film release agent on the surface of seven series aluminum alloys, and can solve the problems of high temperature, foggy surface of aluminum alloy, and long release treatment time. , to achieve the effect of long time and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

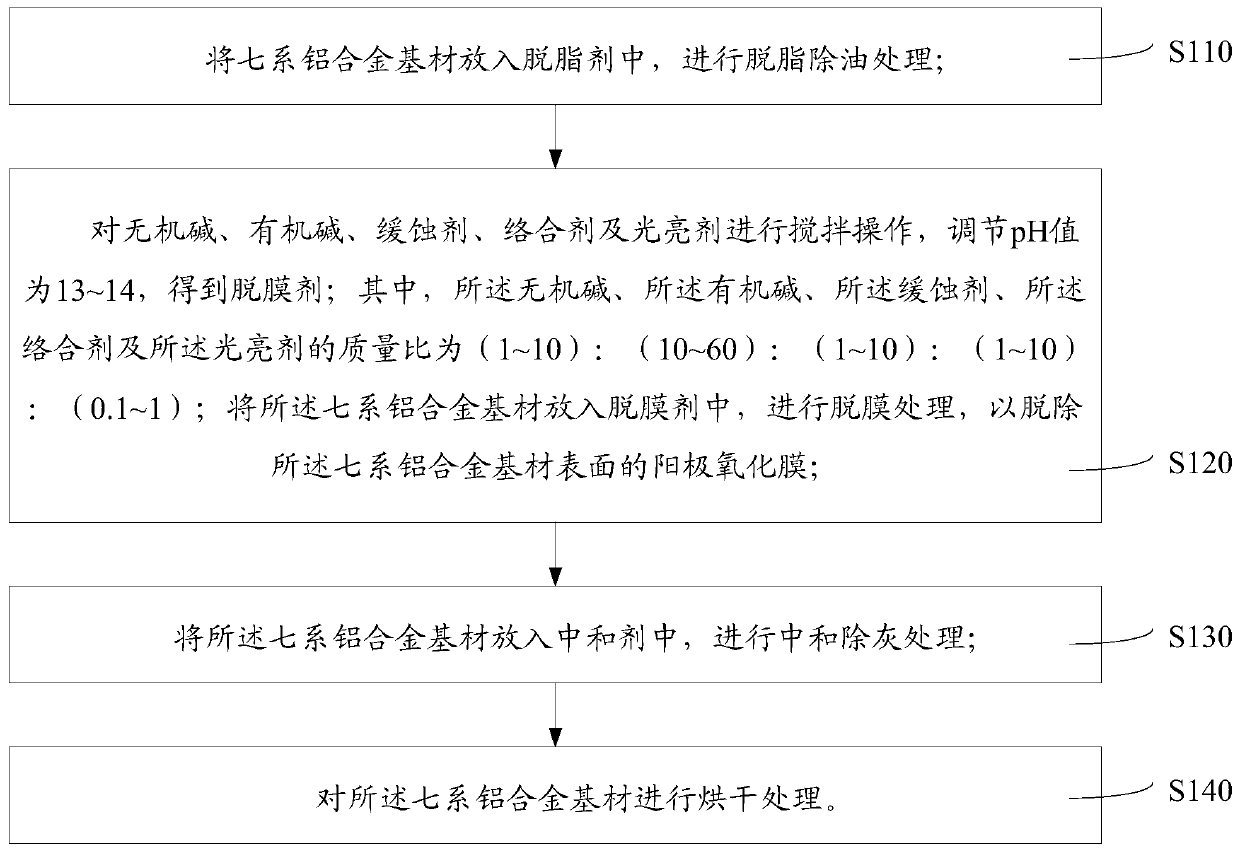

[0051] For an implementation, see figure 1 , a method for removing an anodized film on the surface of a seven-series aluminum alloy, comprising the steps of:

[0052] S110, putting the seven-series aluminum alloy base material into a degreasing agent, and performing degreasing and degreasing treatment.

[0053] In order to better remove the dirt on the surface of the seven-series aluminum alloy substrate after anodic oxidation treatment, for example, in one embodiment, the degreasing agent includes the following components in parts by mass: 10 to 30 parts of sodium carbonate, ethylene di 10-30 parts of disodium amine tetraacetate, 10-30 parts of sodium gluconate, 1-5 parts of alkyl glycoside and 0.5-2 parts of fatty alcohol polyoxyethylene ether.

[0054] It can be understood that the alkalinity of sodium carbonate and sodium gluconate is weak, and disodium edetate is weakly acidic. The combination of the three can obtain a neutral degreasing agent. The cleaning effect of ox...

Embodiment 1

[0075] S111, stirring 10 g of sodium carbonate, 10 g of disodium edetate, 10 g of sodium gluconate, 1 g of alkyl glucoside, 0.5 g of fatty alcohol polyoxyethylene ether, and 1 L of water to obtain a degreasing agent; The base material was put into the degreasing agent, and degreasing and degreasing treatment was performed at a temperature of 55° C. for 3 minutes.

[0076] S121, sodium hydroxide 20g, potassium hydroxide 20g, triethanolamine 500g, sodium silicate 5g, sodium metaaluminate 5g, gelatin 5g, sodium gluconate 10g, sodium citrate 10g, edetate disodium 10g, Trisodium nitrilotriacetate 10g, ethylene thiourea 2g, thiourea 2g, hydroxyethylidene diphosphonic acid 5g and 1L water were stirred, and the pH value was adjusted to 13 to obtain a release agent; the seven-series aluminum alloy substrate put into the release agent, and carry out a release treatment to remove the anodized film on the surface of the seven-series aluminum alloy substrate.

[0077] S131, stir 10 g of s...

Embodiment 2

[0080] S112, stirring 30g of sodium carbonate, 30g of disodium edetate, 30g of sodium gluconate, 5g of alkyl glycoside, 2g of fatty alcohol polyoxyethylene ether and 1L of water to obtain a degreasing agent; Put the material into the degreasing agent, and perform degreasing and degreasing treatment at a temperature of 70° C. for 1 min.

[0081] S122, 30g of sodium hydroxide, 5g of rubidium hydroxide, 5g of cesium hydroxide, 300g of diethanolamine, 300g of triethanolamine, 10g of sodium metaaluminate, 20g of disodium edetate, 5g of thiourea, 2-mercaptobenzo 3g of imidazole and 1L of water were stirred, and the pH value was adjusted to 14 to obtain a release agent; the seven-series aluminum alloy base material was put into the release agent, and a release treatment was performed to remove the Anodized film on the surface of aluminum alloy substrate.

[0082] S132, stirring 50 g of sulfuric acid, 50 g of oxidizing agent, 50 g of stain remover, and 1 L of water to obtain a neutra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap